Preparation method of cellulose based 3D printing wire

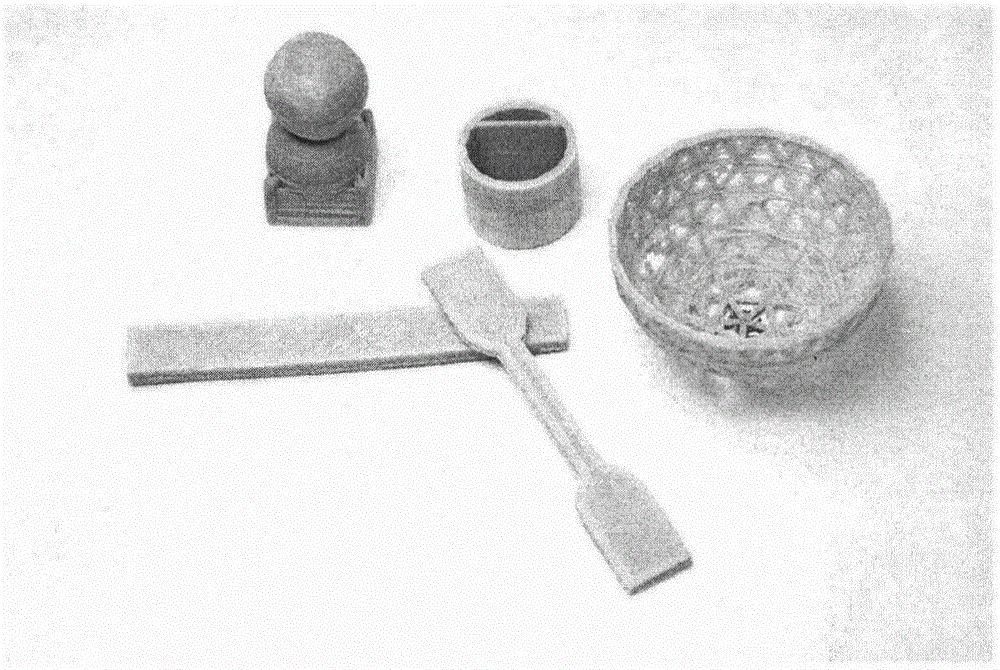

A 3D printing, cellulose-based technology, applied in the field of preparation of cellulose-based 3D printing filaments, can solve the problem of unusable addition of cellulose, and achieve the effects of good shape, low production cost, and widening uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

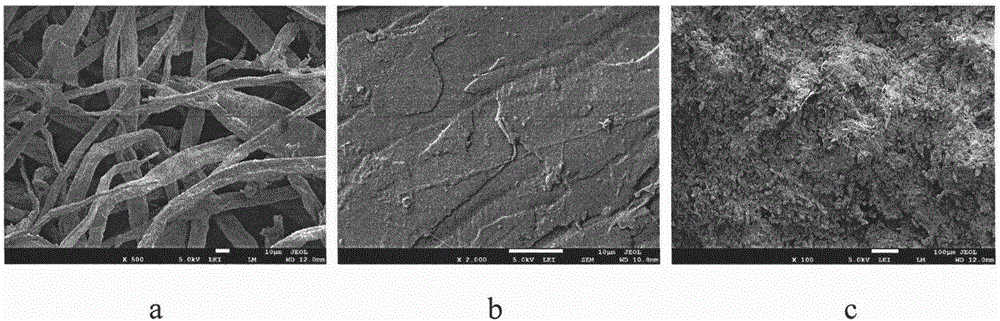

Embodiment 1

[0036] Take 20g of bleached coniferous wood chemical pulp board as a cellulose sample, use a pulverizer to grind it into powder, add 100g of polyethylene glycol with a molecular weight of 400, heat and swell at 120°C in an oil bath for 2h, and swell the swollen The final cellulose is crushed with high strength by a mechanical screw pressing device, and then the polyethylene glycol solution of the crushed cellulose is dispersed in a homogenizer for 10 minutes to obtain a polyethylene glycol dispersion of cellulose microfibers. Use a vacuum pump to filter and remove a large amount of polyethylene glycol in the polyethylene glycol dispersion of cellulose microfibers, then add dichloromethane to disperse and wash the cellulose microfibers under a homogenizer, and remove polyethylene glycol by repeated washing through filtration , until fully washed to obtain a dichloromethane suspension of cellulose microfibrils.

Embodiment 2

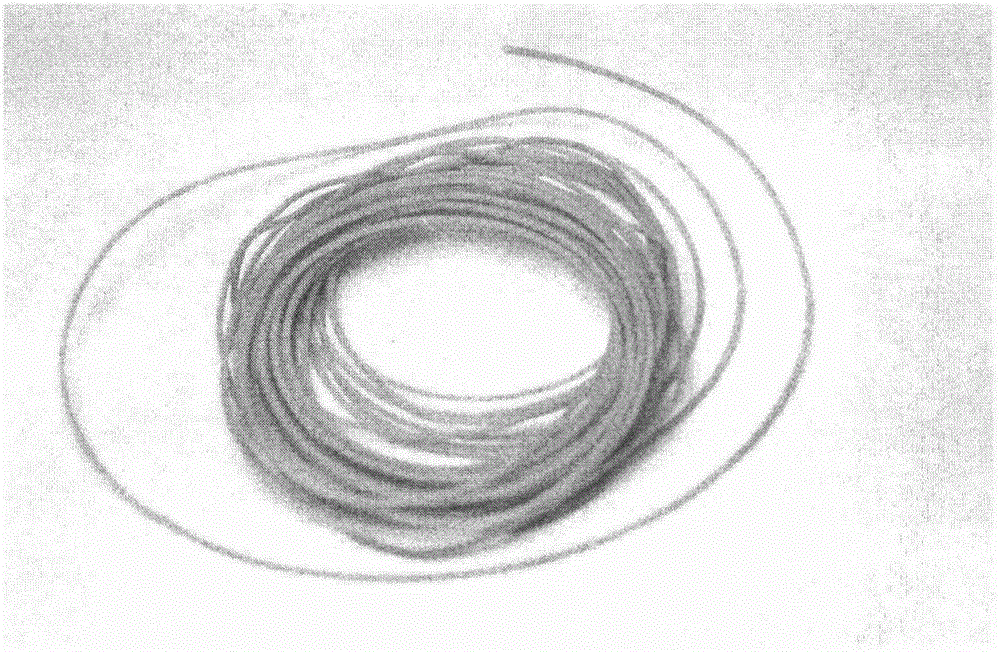

[0038] Take the cellulose microfiber dichloromethane suspension containing 1g of cellulose microfibrils and the PLA dichloromethane solution containing 9g PLA, mix them well at room temperature, stir them evenly at room temperature, mechanically stir them in a water bath at 60°C, and recover a large amount of Dichloromethane solvent, the remaining small amount of dichloromethane was removed by air drying and the cellulose microfiber / PLA composite material was obtained. The mechanical properties were tested by injection molding dumbbell and bar samples. The results showed that the tensile strength of the cellulose microfiber / PLA composite was 70.4MPa, the bending strength was 103.8MPa, and the elongation at break was 10.4%. The melt flow rate of the lower cellulose microfiber / PLA composite was 9.72g / 10min.

Embodiment 3

[0040] Take the cellulose microfiber dichloromethane suspension containing 3g of cellulose microfibers and the PLA dichloromethane solution containing 7g PLA and mix them well at room temperature and mix them evenly, mechanically stir them in a water bath at 60°C, and recover a large amount of Dichloromethane solvent, the remaining small amount of dichloromethane was removed by air drying and the cellulose microfiber / PLA composite material was obtained. The mechanical properties were tested by injection molding dumbbell and bar samples. The results showed that the tensile strength of the cellulose microfiber / PLA composite was 78.8MPa, the bending strength was 105.4MPa, and the elongation at break was 8.9%. The melt flow rate of the lower cellulose microfiber / PLA composite was 0.17g / 10min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com