Method for preparing gold nano particle and graphene composite material through fast reduction

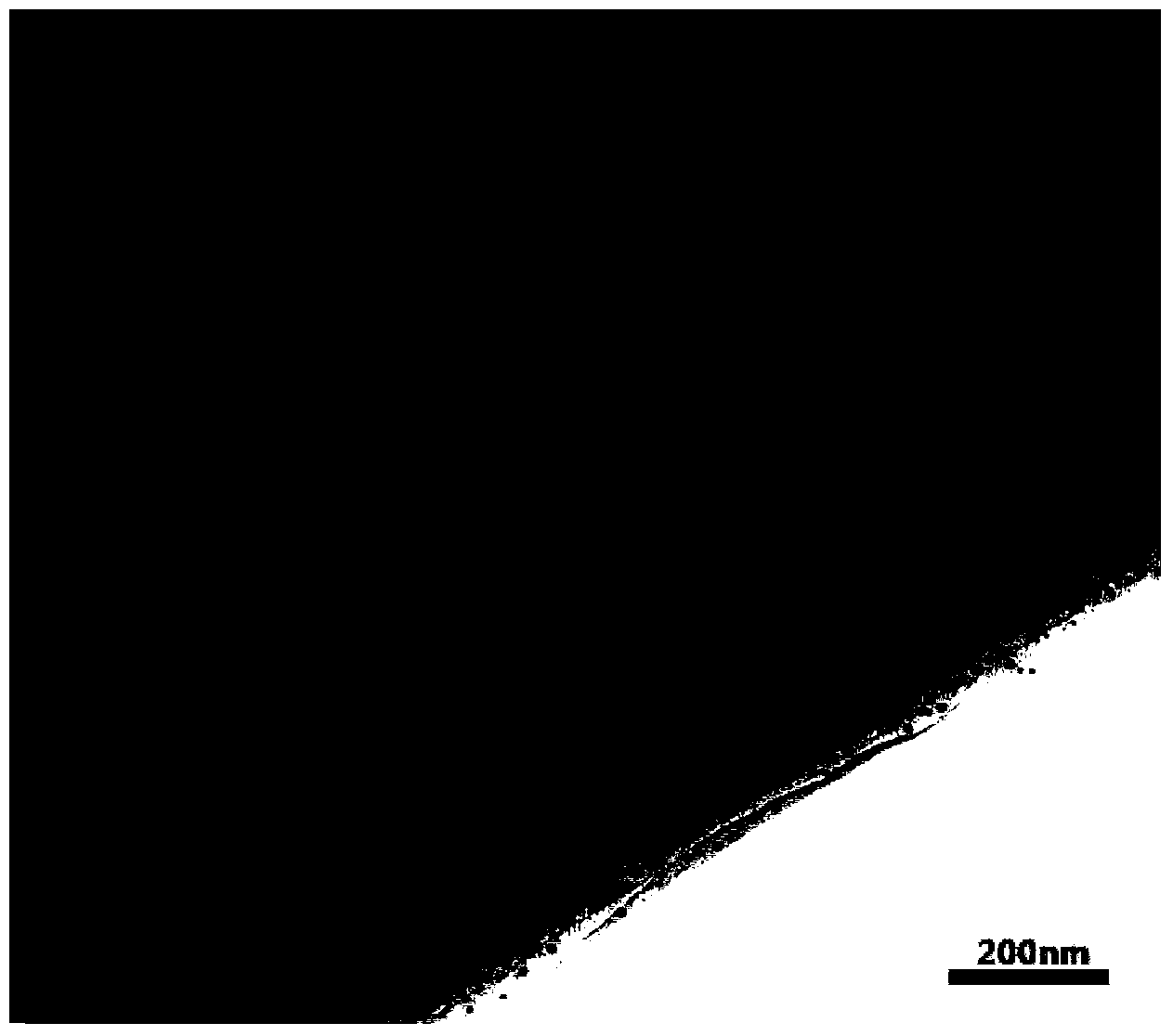

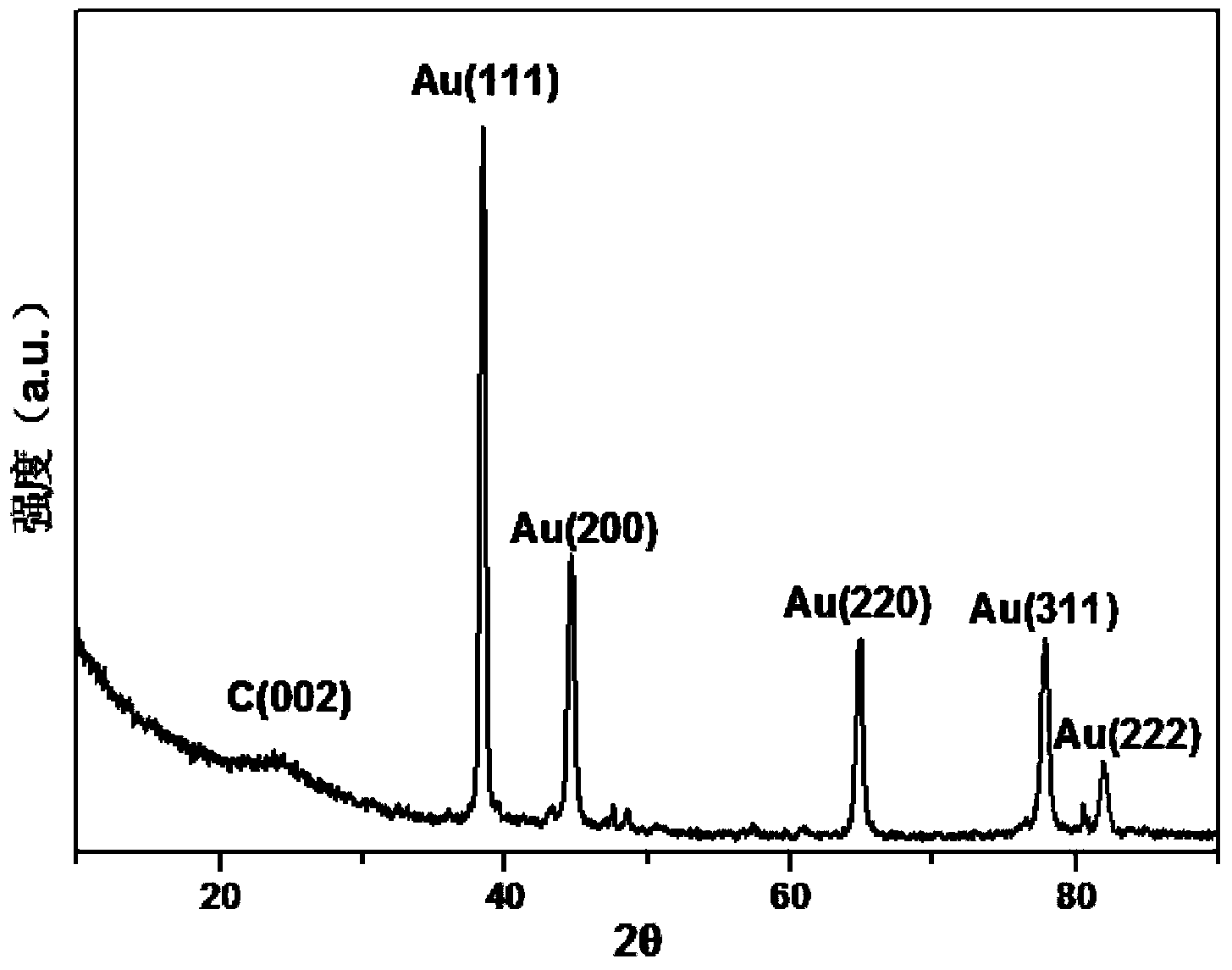

A technology of gold nanoparticles and composite materials, applied in the field of preparation of reduced graphene oxide sheets, gold nanoparticles and composite materials of the two, can solve the problems of poor stability, easy agglomeration, and excessive surface energy of nanoparticles, and achieves The effect of strong repeatability, uniform distribution and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

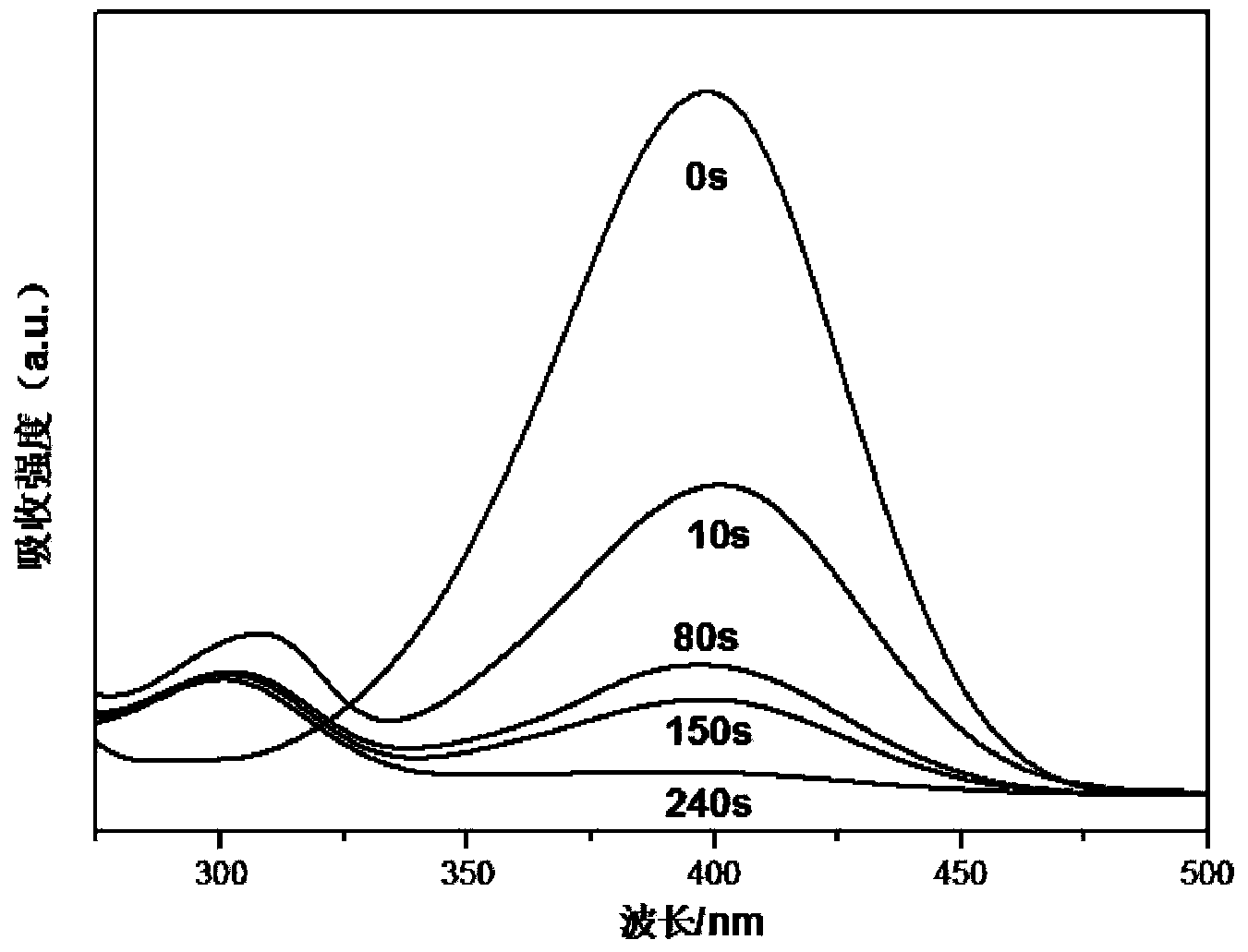

Examples

preparation example Construction

[0031] Preparation of graphene oxide: using the improved Hummers method to prepare graphite oxide to obtain graphite oxide gel;

[0032] Described utilizing improved Hummers method to prepare graphite oxide specific steps are:

[0033] A. Low temperature reaction stage:

[0034] A1. Under the condition of an ice-water bath, take 20-23ml of concentrated sulfuric acid with a mass fraction of 98% in a three-necked flask, stir for 5-10mins, then add graphite powder that is 4.35-4.55% by weight with the concentrated sulfuric acid solution, Particle size ≤ 30um, stirring for 15-30mins to obtain a mixed solution of concentrated sulfuric acid and graphite powder,

[0035] A2. Take by weighing the sodium nitrate that is 2.50-3.60% by weight of the above-mentioned concentrated sulfuric acid and graphite powder mixed solution and join in the concentrated sulfuric acid and graphite powder mixed solution, stir for 10-15mins,

[0036] A3. Finally, the weight ratio of the mixed solution ob...

Embodiment 1

[0049] 1. Low temperature reaction: 20-23ml of concentrated sulfuric acid (98%), stirred in an ice-water bath for 5-8mins, added 1000mg of graphite powder, reacted for 15-20mins, added 0.5-0.9g of sodium nitrate, mixed for 10-15mins, 3000mg high Potassium manganate was added slowly to prevent the temperature from rising suddenly, and stirred for 80-100mins, and the above steps were all in ice water bath.

[0050] 2. Medium temperature reaction: heat up, water bath temperature is about 35-36°C, and react for 30-50mins

[0051] 3. High temperature reaction: Add 40-50ml deionized water, add dropwise, then raise the temperature to 90-100°C, stir for 30-40mins, add 10-15ml hydrogen peroxide dropwise, stir for 10-20mins, wait for the solution after reaction Cool, add deionized water, let stand, remove supernatant

[0052] 4. Repeat the centrifugation of the solution obtained in 3 for 5-6 times, the rotating speed is 13000-15000rpm, the time of each centrifugation is 10-15mins, and ...

Embodiment 2

[0061] The difference between this embodiment and Example 1 is that in step 7, the water bath is at 90° C. for 2 hours, and the others are the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com