3D lithium-philic porous metal current collector, negative electrode, and preparation and application thereof

A technology of porous current collectors and porous metals, applied in battery electrodes, lithium batteries, electrode carriers/current collectors, etc., can solve the problems of insufficient current density reduction and inability to effectively suppress lithium dendrites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] The thickness of the copper foam current collector is 50 μm, the porosity is 50%, and the hole spacing is 100 μm;

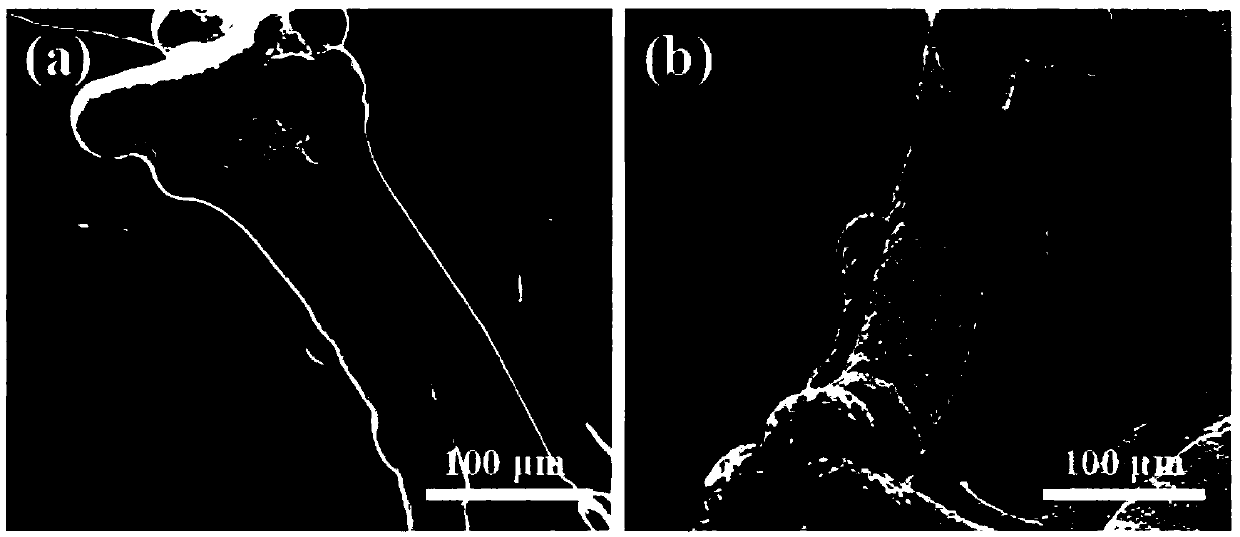

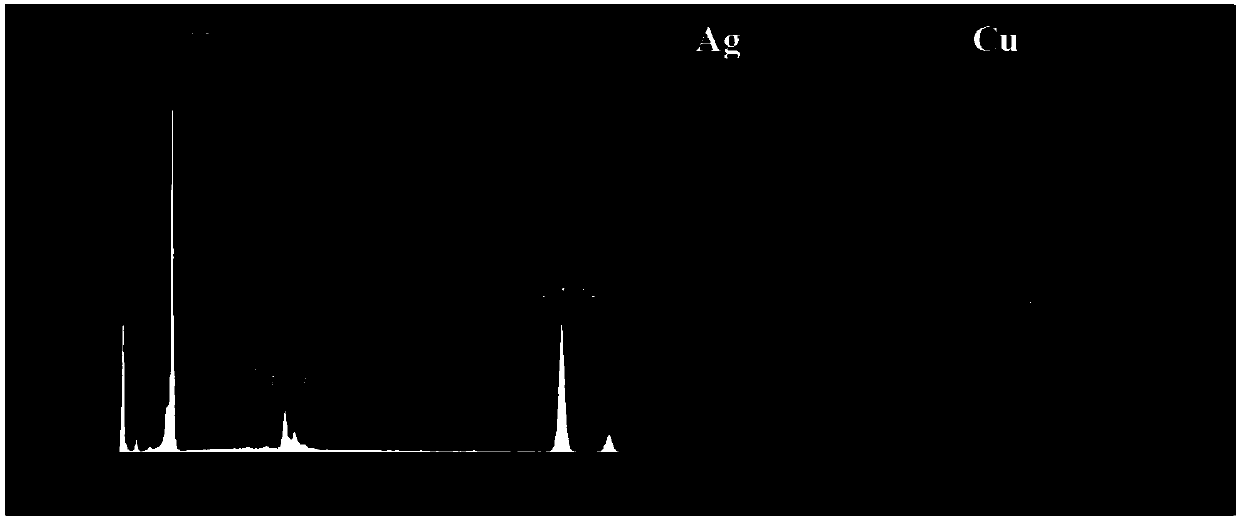

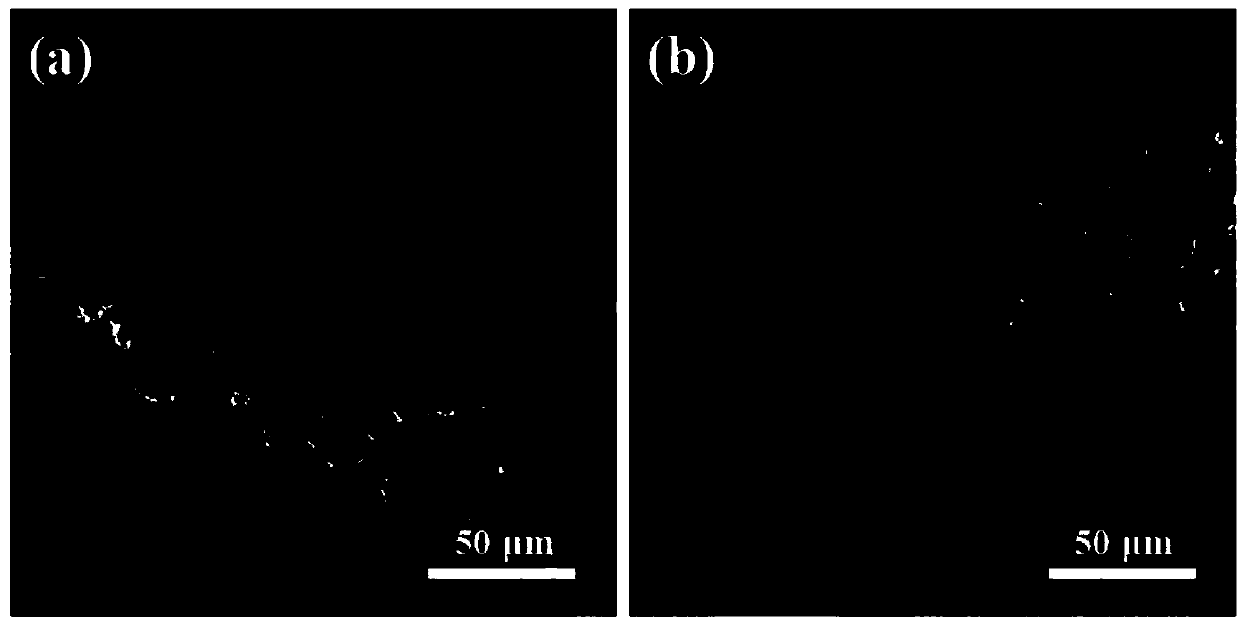

[0087] The copper foam current collector (Cu foam) is the working electrode, and Ag is the counter electrode, and silver particles are electrodeposited on the copper foam current collector (Cu foam) (the plating solution for electrodeposition is: sodium thiosulfate (200g / L), coke Potassium sulfite (40g / L), silver nitrate (30g / L), OP-10 (1mL / L) and the balance is water), at 1mA / cm 2 Ag@Cu foam was obtained by lower deposition for 10s; the particle size of Ag was ~500nm.

[0088] The prepared Ag@Cu foam was used as the working electrode, the metal lithium sheet was used as the counter electrode, and 1M LiTFSI / DOL:DME (volume ratio=1:1) contained 1%wt LiNO 3 Assemble coin cells for the electrolyte, conduct lithium deposition tests and charge-discharge cycle tests. At the same time, the corresponding deposition test and charge-discharge cycle test were carri...

Embodiment 2

[0092] The thickness of the titanium foam current collector is 20 μm, the porosity is 30%, and the pore spacing is 80 μm;

[0093] The porous titanium current collector (porous Ti) is the working electrode, platinum is the counter electrode, and the platinum particles are electrodeposited on the porous titanium (porous Ti) current collector (the plating solution for electrodeposition is: chloroplatinic acid hexahydrate (1.2g / L) , Tween 20 (0.6g / L) and the balance is water), at 1.5mA / cm 2 The Pt@porous Ti prepared by deposition for 20s. The particle size of Pt is 200 nm.

[0094] The prepared Pt@porous Ti was used as the working electrode, the metal lithium sheet was used as the counter electrode, and 1M LiTFSI / DOL:DME (volume ratio=1:1) contained 1%wt LiNO 3 Assemble coin cells for the electrolyte, conduct lithium deposition tests and charge-discharge cycle tests. At the same time, the corresponding deposition test and charge-discharge cycle test were carried out with pure ...

Embodiment 3

[0097] The thickness of the porous nickel-manganese current collector is 30 μm, the porosity is 45%, and the pore spacing is 70 μm;

[0098] The porous Ni-Mn current collector is used as the working electrode, and the Ag-Au alloy is used as the counter electrode. On the porous Ni-Mn current collector, Ag-Au particles are electrodeposited (the plating solution for electrodeposition is sulfur Sodium disulfate (180g / L), potassium metabisulfite (30g / L), silver nitrate (20g / L), chloroauric acid (1g / L), sodium dodecylbenzenesulfonate (0.3 / L) and The balance is water), at 1.5mA / cm 2 Ag-Au@porous Ni-Mn prepared by deposition for 30s; the particle size of Ag-Au particles is 100nm.

[0099] The prepared Ag-Au@porous Ni-Mn was used as the working electrode, the metal lithium sheet was used as the counter electrode, and 1MLiTFSI / DOL:DME (volume ratio=1:1) contained 1%wt LiNO 3 Assemble coin cells for the electrolyte, conduct lithium deposition tests and charge-discharge cycle tests. At...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com