Two-dimensional anatase TiO2/g-C3N4 composite material, as well as preparation method and application thereof

A technology of composite materials and anatase, which is applied in the field of two-dimensional anatase TiO2/g-C3N4 composite materials and its preparation, can solve the problems of inability to exert photocatalytic performance, poor photocatalytic performance, and enlarged band gap , to achieve high-efficiency photocatalytic hydrogen production and photodegradation of organic matter performance, excellent stability, and large lateral size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

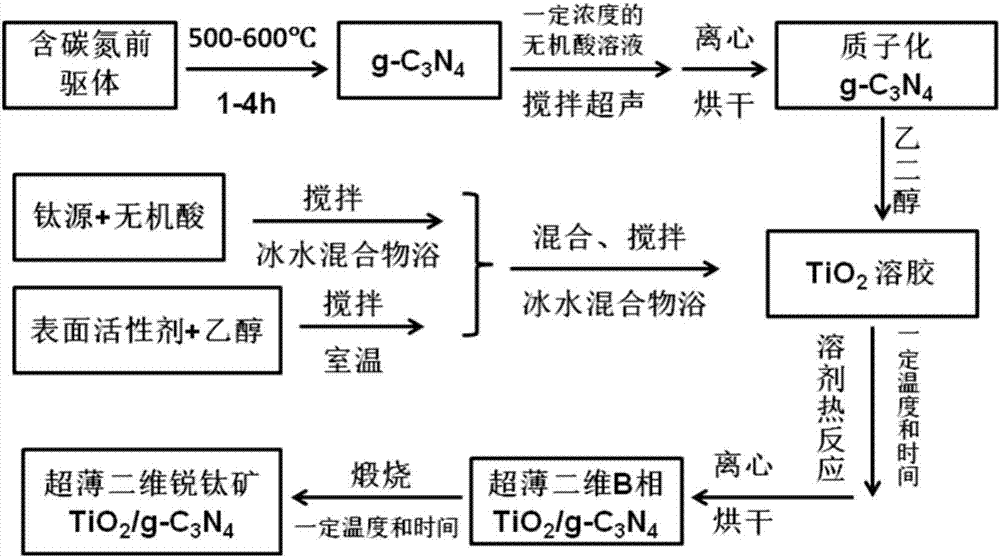

[0048] A two-dimensional anatase TiO 2 / g -C 3 N 4 The manufacturing process of composite materials is as follows: figure 1 shown, including the following steps:

[0049] 1) Using melamine as the precursor of carbon-nitrogen compounds, calcining at 550°C in an air atmosphere to obtain bulk g-C 3 N 4 ; 100 mg block g-C 3 N 4 , after ultrasonic protonation in 0.5M hydrochloric acid for 6h, add to 40mL ethylene glycol and ultrasonically stir until uniformly dispersed;

[0050] 2) Add 0.2mL of surfactant P123 into 4mL of ethanol and stir for 15min;

[0051] 3) Add 1 mL of tetraisopropyl titanate (TTIP) to 0.6 mL of concentrated hydrochloric acid under ice-water bath and magnetic stirring, then continue to stir for 15 min, and add the obtained solution to ethanol containing surfactant obtained in step 2). solution, continue to stir for 30min;

[0052] 4) Add the product obtained in step 3) to the solution obtained in step 1), stir it evenly with ultrasonic waves, then tran...

Embodiment 2

[0058] A two-dimensional anatase TiO 2 / g -C 3 N 4 The preparation of composite material, method is with embodiment 1, difference is:

[0059] In step 1), melamine is calcined twice to obtain flake g-C 3 N 4 , and the sheet g-C 3 N 4 The dosage is 240mg;

[0060] Step 4) React 24h in the hydrothermal reactor; Get the TiO of 200mg gained Bronze phase 2 / g -C 3 N 4 The composite powder was calcined in a muffle furnace at 450 °C for 4 h to obtain anatase phase two-dimensional TiO 2 / g -C 3 N 4 composite material.

Embodiment 3

[0062] A two-dimensional anatase TiO 2 / g -C 3 N 4 The preparation of composite material, method is with embodiment 1, difference is:

[0063] In step 1), melamine is calcined twice to obtain flake g-C 3 N 4 , and the sheet g-C 3 N 4 The dosage is 140mg;

[0064] Step 4) react 20h in the hydrothermal reactor; The TiO of Bronze phase 2 / g -C 3 N 4 The composite powder was calcined in a muffle furnace at 420 °C for 4 h to obtain anatase phase two-dimensional TiO 2 / g -C 3 N 4 composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com