Fuel cell film electrode and preparation method thereof

A fuel cell membrane and fuel cell technology, applied in the direction of fuel cells, battery electrodes, fuel cell components, etc., can solve problems such as difficulty in fully infiltrating catalyst particles into full contact, unsuitable for large-scale production, and large gas transfer resistance. Achieve the effect of improving the comprehensive performance of the battery, improving the utilization rate of the catalyst, and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

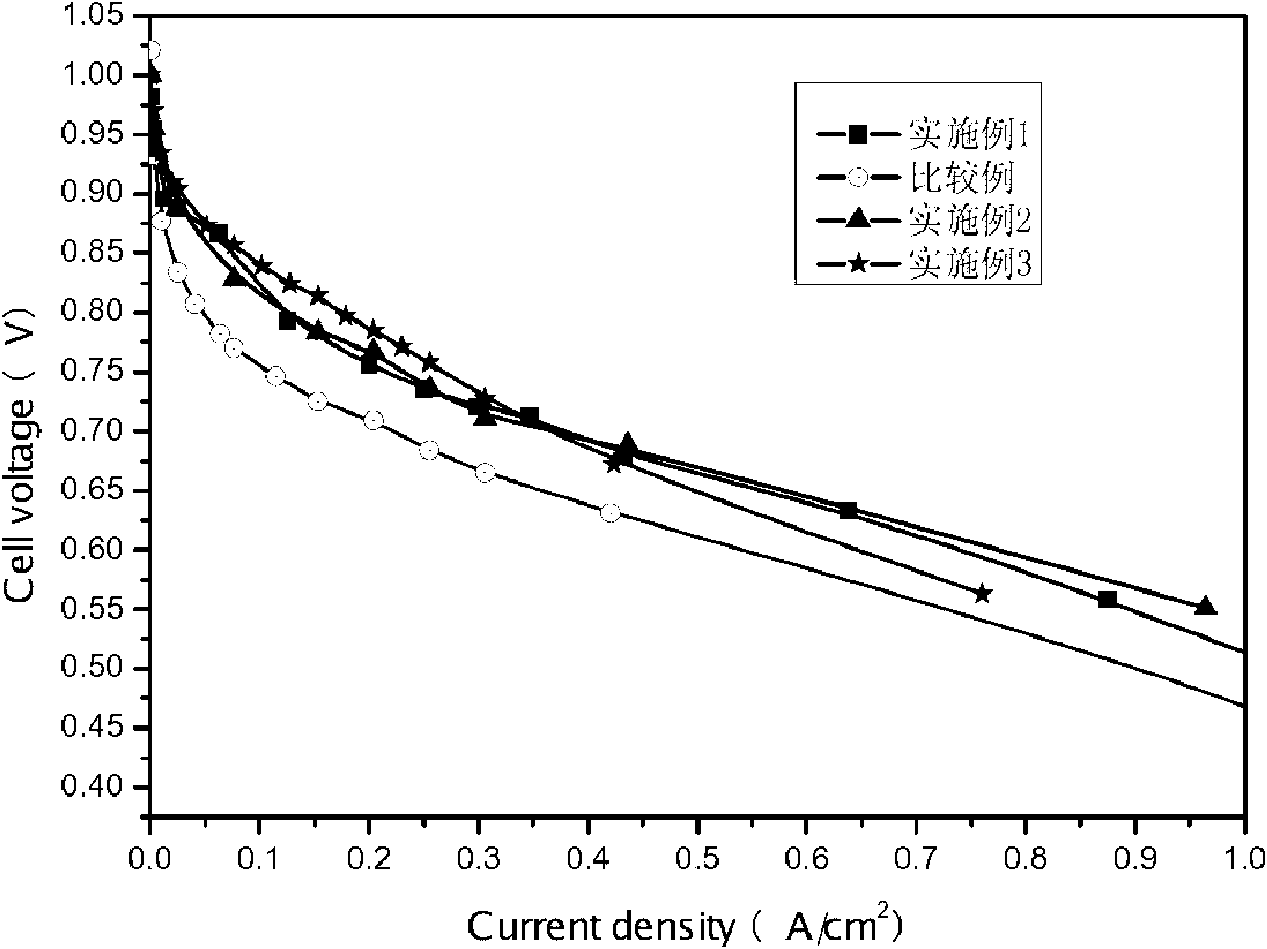

Embodiment 1

[0031] Dilute the PVDF emulsion to 3%, then put the carbon paper (Toray TGPH-090) into the prepared emulsion and soak for 2 minutes, take it out and blow it dry with a hair dryer, repeat 3~4 times until the PVDF content is 20%, and then put Put it in a high-temperature oven at 200°C for 50 minutes.

[0032] Weigh 2g XC-72 carbon powder and 0.5g PVDF powder, put them into a high-speed ball mill, and grind for 2 minutes (25000 rpm). Apply the treated composite dry powder to the surface of the hydrophobically treated carbon paper by scraping, and the carbon powder load is 2.0mg / cm 2 . Then put it into a high-temperature oven at 200°C and burn for 50 minutes.

[0033] Coating part of the hydrophobic catalyst layer on the surface of the microporous layer (anode load 0.2mg / cm 2 , cathode load 0.5mg / cm 2). Weigh John Matthey Pt / C catalyst into a beaker, add a small amount of deionized water to soak the catalyst, add absolute ethanol at 30ml of absolute ethanol / g of catalyst, mix...

Embodiment 2

[0037] Dilute the PTFE emulsion to 3%, then put the carbon cloth (NOK, H2315) into the prepared emulsion and soak for 2 minutes, take it out and blow it dry with a hair dryer, repeat 3 to 4 times until the content of PTFE is 20%, and then put it in Burn in a high temperature oven at 350°C for 50 minutes.

[0038] Weigh 5 g of carbon nanofibers and 1.5 g of PTFE powder, put them into a high-speed ball mill, and grind for 1 minute (20000 rpm). Apply the processed composite dry powder to the surface of the hydrophobically treated carbon paper by electrostatic spraying and rolling, and the carbon powder load is 3.0mg / cm 2 . Then put it into a high-temperature oven at 350° C. and burn for 50 minutes.

[0039] Coating a hydrophobic catalyst layer on the surface of the microporous layer (anode load 0.1mg / cm 2 , cathode load 0.4mg / cm 2 ). Weigh John Matthey Pt / C catalyst into a beaker, add a small amount of deionized water to soak the catalyst, add isopropanol at 50ml isopropanol...

Embodiment 3

[0044] Dilute the PTFE emulsion to 1%, then put carbon paper (Toray TGPH-090) into the prepared emulsion and soak for 2 minutes, take it out and dry it in the oven, repeat 5~6 times until the content of PTFE is 50%, then put Put it in a high-temperature oven at 350°C for 50 minutes.

[0045] Weigh 5g of acetylene black and 1.5g of PTFE powder, put them into a high-speed ball mill, and grind for 1 minute (20000 rpm). Apply the treated composite dry powder to the surface of the hydrophobically treated carbon paper by electrostatic spraying and rolling, and the loading of acetylene black is 1.0mg / cm 2 . Then put it into a high-temperature oven at 350° C. and burn for 50 minutes.

[0046] Coating a hydrophobic catalyst layer on the surface of the microporous layer (anode load 0.1mg / cm 2 , cathode load 0.4mg / cm 2 ). Weigh the John Matthey Pt / C catalyst into a beaker, add a small amount of deionized water to wet the catalyst, add isopropanol at 50ml ethylene glycol / g catalyst, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com