A controlled preparation method of ordered titanium dioxide nanomaterials

A titanium dioxide and nanomaterial technology, applied in the directions of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of expensive titanium substrates, uncontrollable preparation of different morphologies, etc., achieving convenient post-processing and strong repeatability , the effect of easy availability of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Measure 12.5ml mass fraction respectively and be that the concentrated hydrochloric acid of 37% and 12.5ml deionized water form mixed solution;

[0034] (2) Drop 2.5ml of tetra-n-butyl titanate into the above solution, and stir vigorously to mix evenly while the titanate is rapidly hydrolyzed;

[0035] (3) Put the homogeneously mixed suspension into a polytetrafluoroethylene-lined stainless steel autoclave, and conduct a hydrothermal reaction at 180° C. for 3 hours;

[0036] (4) After the reaction, the precipitated product was washed with distilled water and absolute ethanol, and then dried at 80° C. to obtain nanoclusters composed of titanium dioxide nanorods.

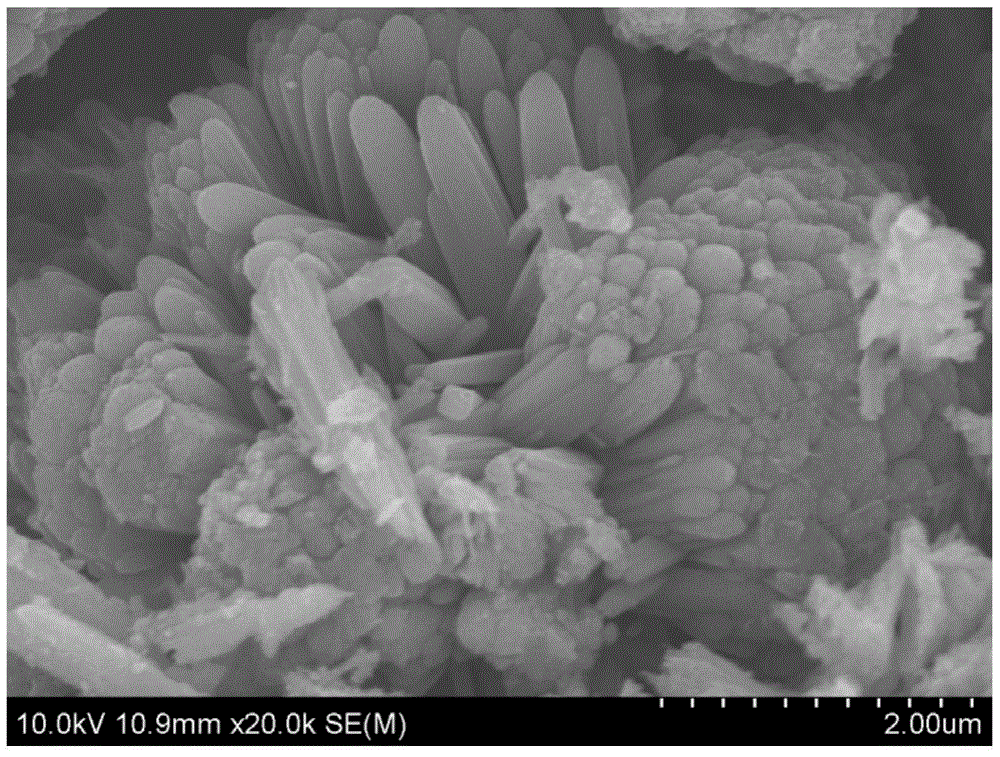

[0037] The product obtained in step (4) is characterized by its structure and crystal form with SEM and XRD respectively, figure 1 The TiO obtained under this reaction condition 2 Morphology of nanoclusters. It can be seen from the figure that the obtained TiO 2 Nanoclusters are composed of nanorods, an...

Embodiment 2

[0039] (1) measure the vitriol oil of 12.5ml and the deionized water of 12.5ml respectively to form mixed solution;

[0040] (2) Drop 5ml of isopropyl titanate into the above solution, and stir vigorously to make it evenly mixed while the titanate is rapidly hydrolyzed;

[0041] (3) Put the homogeneously mixed suspension into a polytetrafluoroethylene-lined stainless steel autoclave, and conduct a hydrothermal reaction at 170°C for 6 hours;

[0042] (4) After the reaction, the precipitated product was washed with distilled water and absolute ethanol, and then dried at 60° C. to obtain ordered nanoflowers composed of titanium dioxide nanorods.

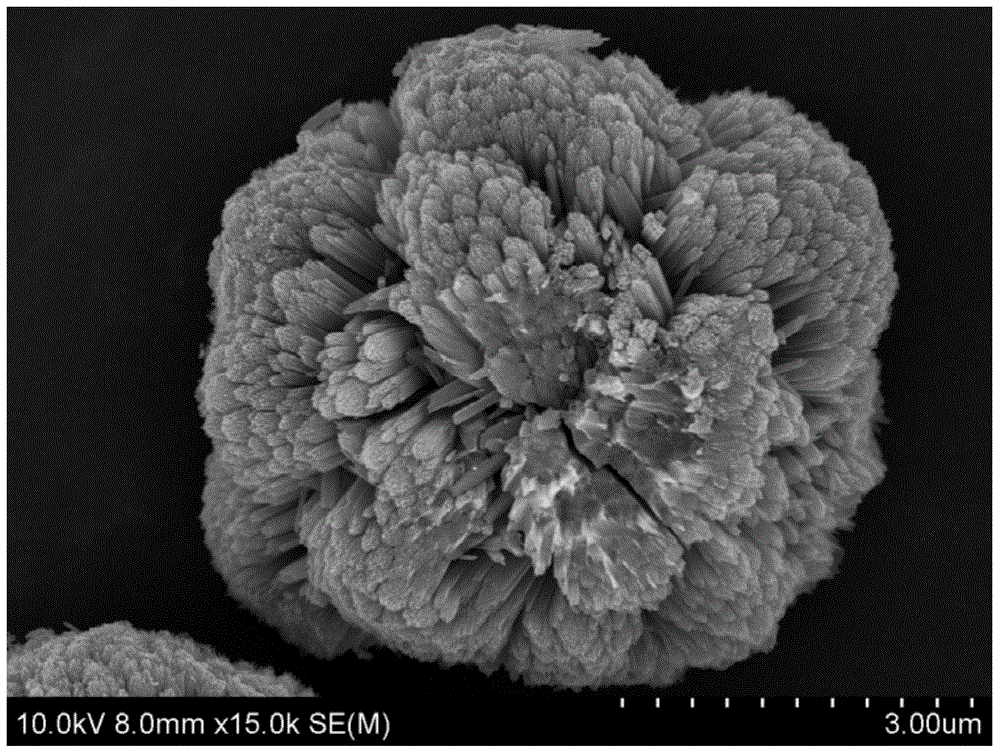

[0043] The product obtained in step (4) is characterized by its structure and crystal form with SEM and XRD respectively, figure 2 The TiO obtained under this reaction condition 2 Morphology of nanoflowers. It can be seen from the figure that the obtained TiO 2 Nanoflowers are more ordered. It can be seen from the XRD pattern that...

Embodiment 3

[0045] (1) Measure the concentrated nitric acid of 5ml and 15ml deionized water respectively to form a mixed solution;

[0046] (2) Drop 3ml of tetraethyl titanate into the above solution, and stir vigorously to make it evenly mixed while the titanate is rapidly hydrolyzed;

[0047](3) Put the evenly mixed suspension into a PTFE-lined stainless steel autoclave, and perform a hydrothermal reaction at 180°C for 3 hours;

[0048] (4) After the reaction, the precipitated product is washed with distilled water and absolute ethanol, and then dried at 80° C. to obtain titanium dioxide microspheres composed of titanium dioxide nanorods.

[0049] The product obtained in step (4) was characterized by SEM and XRD for its structure and crystal form, respectively, image 3 TiO obtained for this reaction condition 2 Morphology of the microspheres. As can be seen from the figure, the obtained TiO 2 The diameter of the microspheres is about 8 μm, and the microspheres are also made of TiO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com