Preparation method of multilevel structural titanium dioxide nano flower string

A technology of titanium dioxide and nanoflowers, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., to achieve the effects of low cost, wide adjustable range of parameters, and simple process and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Take 0.5 milliliters of tetrabutyl titanate, 40 milliliters of acetic acid and 0.1 gram of silver nitrate to prepare a mixed solution, and stir;

[0031] (2) Disperse 0.05 gram of titanium dioxide nanobelts in the above-mentioned solution, stir to make it evenly mixed;

[0032] (3) Put the above suspension into a polytetrafluoroethylene-lined stainless steel autoclave, and conduct a hydrothermal reaction at 150° C. for 6 hours;

[0033] (4) After the reaction, the precipitated product is washed with distilled water and absolute ethanol, dried at 80° C. for 6 to 24 hours, and ground into powder;

[0034] (5) The obtained powder is placed in a muffle furnace and calcined at 450° C. for 30 minutes to obtain a multi-level titanium dioxide nano flower string.

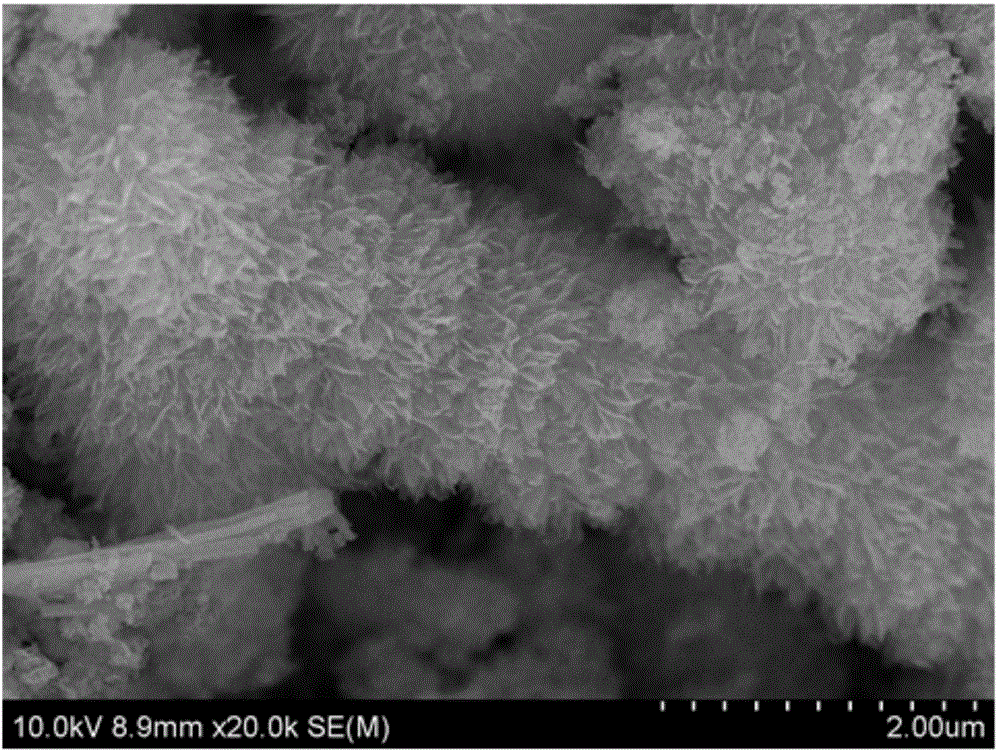

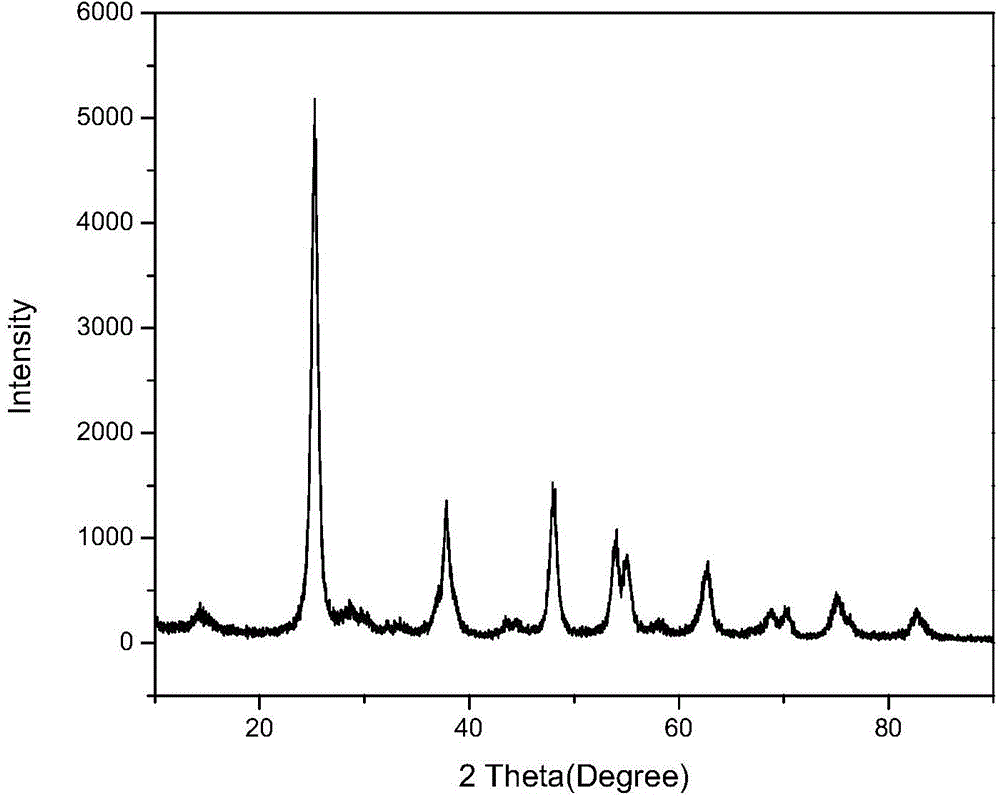

[0035] The resulting product was characterized by its structure and crystal form by SEM and XRD, respectively, figure 1 The morphology of titanium dioxide obtained under this reaction condition. It can be seen ...

Embodiment 2

[0037] (1) Take 0.5 milliliters of tetrabutyl titanate, 40 milliliters of acetic acid and 0.1 gram of silver nitrate to prepare a mixed solution, and stir;

[0038] (2) Disperse 0.05 gram of titanium dioxide nanobelts in the above-mentioned solution, stir to make it evenly mixed;

[0039] (3) Put the above suspension into a polytetrafluoroethylene-lined stainless steel autoclave, and conduct a hydrothermal reaction at 150° C. for 8 hours;

[0040] (4) After the reaction, the precipitated product is washed with distilled water and absolute ethanol, dried at 80° C. for 6 to 24 hours, and ground into powder;

[0041] (5) The obtained powder is placed in a muffle furnace and calcined at 450° C. for 30 minutes to obtain a multi-level titanium dioxide nano flower string.

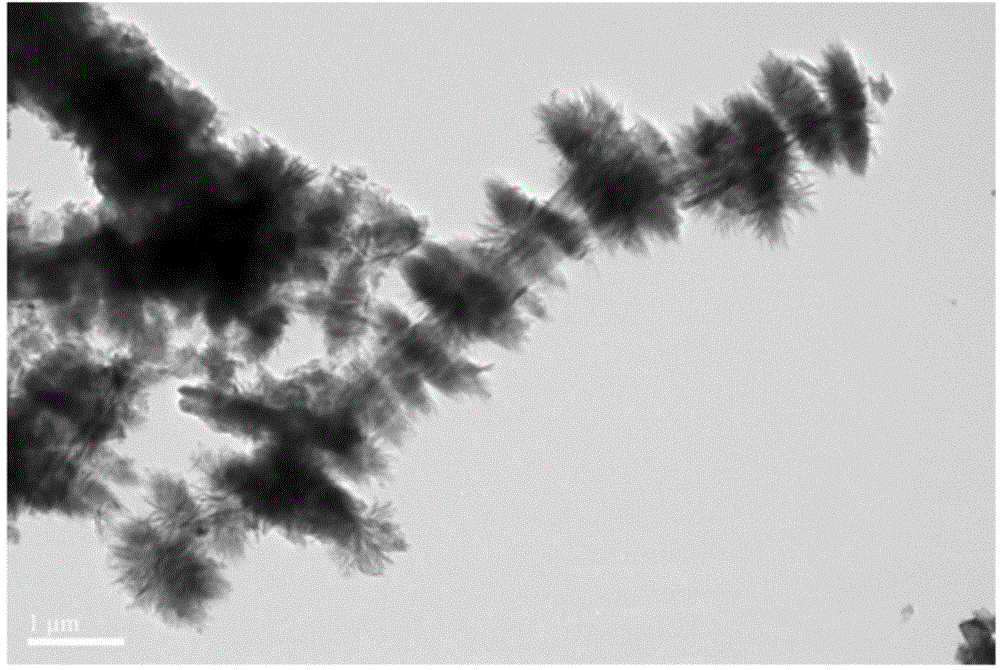

[0042] The structures of the obtained products were characterized by TEM, figure 2 The morphology of titanium dioxide obtained under this reaction condition. It can be seen from the figure that under this cond...

Embodiment 3

[0044] (1) Take 3.5 milliliters of tetraethyl titanate, 35 milliliters of oxalic acid and 0.35 grams of silver citrate to prepare a mixed solution, and stir;

[0045] (2) 0.35 gram of titanium dioxide nanobelts are dispersed in the above-mentioned solution, and stirred to make it evenly mixed;

[0046] (3) Put the suspension into a polytetrafluoroethylene-lined stainless steel autoclave, and conduct a hydrothermal reaction at 180° C. for 6 hours;

[0047] (4) After the reaction, the precipitated product is washed with distilled water and absolute ethanol, dried at 80° C. for 6 to 24 hours, and ground into powder;

[0048] (5) The obtained powder is placed in a muffle furnace and calcined at 450° C. for 30 minutes to obtain a multi-level titanium dioxide nano flower string.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com