Flaky bismuth subnitrate and preparation method thereof

A technology of bismuth nitrate and flaky base, applied in chemical instruments and methods, bismuth compounds, inorganic chemistry, etc., can solve the problems of low photoconversion efficiency, electrons and holes cannot migrate in time, achieve high catalytic activity, reduce production The effect of wide adjustable range of cost and parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

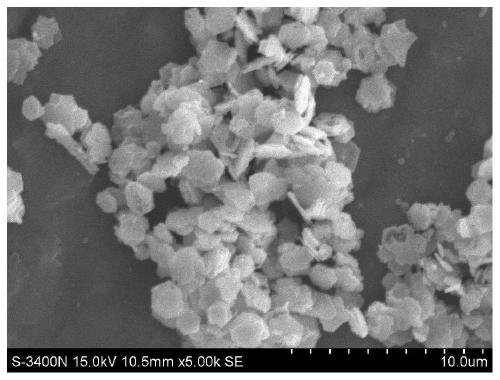

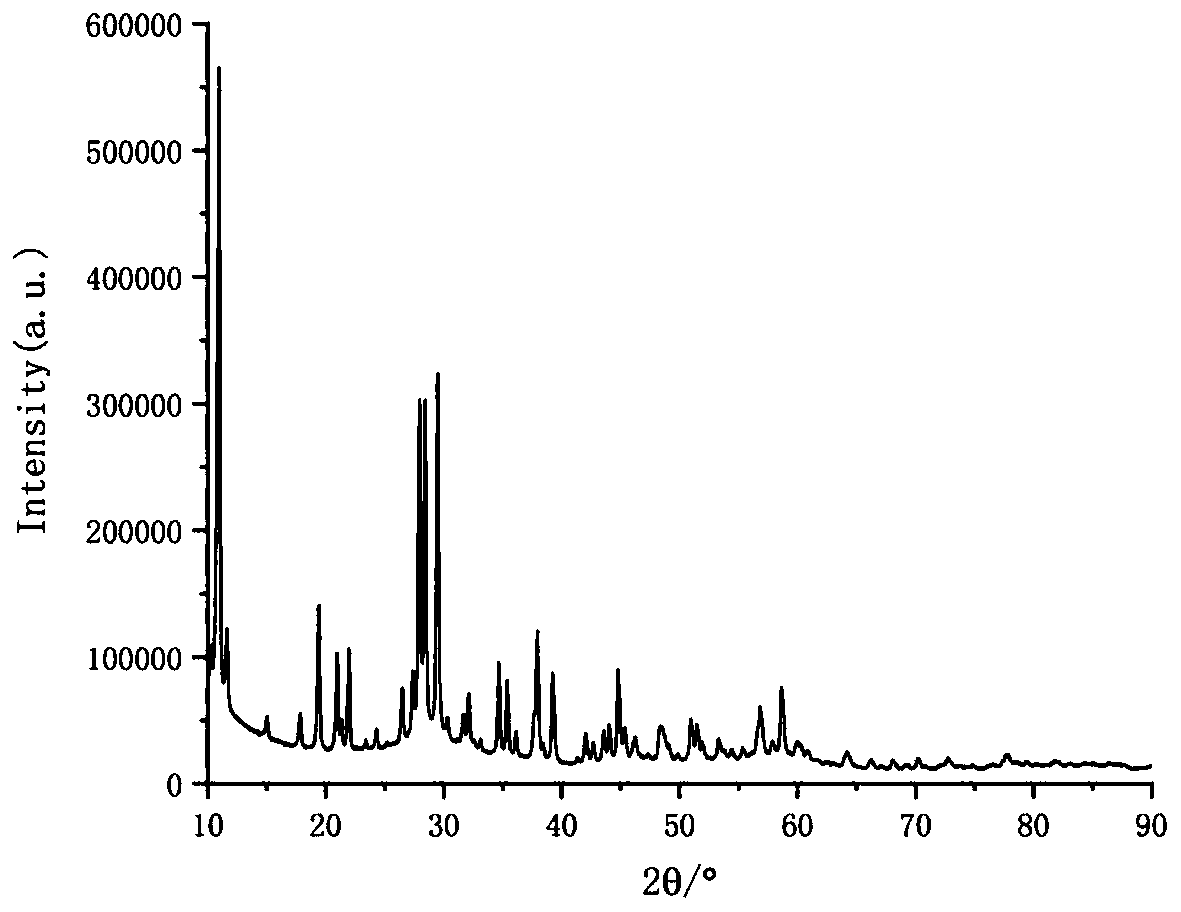

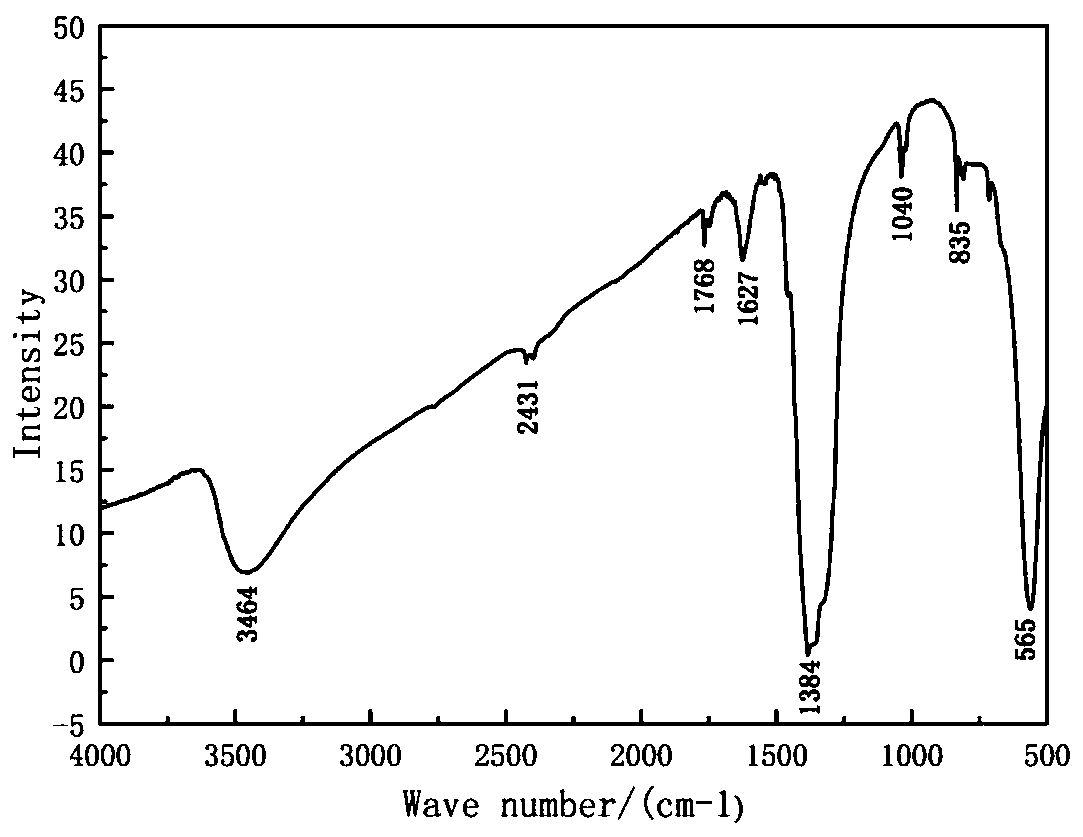

[0037] A flaky bismuth subnitrate with the chemical formula Bi 6 o 6 (OH) 2 (NO 3 ) 4 2H 2 O. The shape of the flaky bismuth subnitrate is hexagonal flaky, and the particle size (diameter) is 2-3um.

[0038] The preparation method of described flaky bismuth subnitrate, concrete steps are:

[0039] 1) Measure 120.0 mL of deionized water into a reaction vessel, add 30.0 mL of concentrated HNO with a concentration of 65-68% by mass 3 , ultrasonic treatment promotes uniform dispersion of the solution to obtain a nitric acid solution;

[0040] 2) Weigh 17.4gBi(NO 3 ) 3 ·5H 2 O, join 150mL above-mentioned step 1) in the solution gained, ultrasonic dispersion, make it dissolve uniformly, obtain bismuth nitrate solution;

[0041] 3) Measure 15mL of the solution obtained in the above step 2), add it to a single-necked flask filled with 85.0mL deionized water, stir continuously and heat to 60°C, add 40mL aqueous solution dissolved with 4gHTMA after 30min, and continue heating...

Embodiment 2

[0046] A flaky bismuth subnitrate with the chemical formula Bi 6 o 6 (OH) 2 (NO 3 ) 4 2H 2 O. The shape of the flaky bismuth subnitrate is hexagonal flaky, and the particle size (diameter) is 2-3um.

[0047] The preparation method of described flaky bismuth subnitrate, concrete steps are:

[0048] 1) Measure 120.0 mL of deionized water into a reaction vessel, add 30.0 mL of concentrated HNO with a concentration of 65-68% by mass 3 , ultrasonic treatment promotes uniform dispersion of the solution to obtain a nitric acid solution;

[0049] 2) Weigh 17.4gBi(NO 3 ) 3 ·5H 2 0, join in the solution that 150mL above-mentioned step (1) gains, ultrasonic dispersion makes it dissolve uniformly, obtains bismuth nitrate solution;

[0050] 3) Measure 15mL of the solution obtained in the above step (2), add it to a single-necked flask filled with 100mL deionized water, stir continuously and heat to 80°C, add 40mL aqueous solution dissolved with 6gHTMA after 30min, and continue h...

Embodiment 3

[0054] Degradation experiment of dye wastewater

[0055] Weigh 0.03 g of the sample, add 100 mL of RhB aqueous solution respectively, in which the concentration of RhB is 10 mg / L, and stir for 30 min in the dark to make the dye reach the adsorption / desorption equilibrium on the surface of the catalyst. Then turn on the xenon lamp light source (300W xenon lamp, the optical filter filters out light waves with a wavelength below 400nm), carry out photocatalytic reaction under visible light irradiation, and detect the supernatant with a spectrophotometer. According to the Lambert–Beer law, the change in the intensity of the characteristic absorption peak of organic matter can be used to quantitatively calculate the change in its concentration. When the light-absorbing substances are the same and the thickness is the same, the change of the absorbance can be used to directly represent the change of the solution concentration. Because RhB has a characteristic absorption peak at 554...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com