Holmium/ytterbium-codoped bisumth tungstate fluorescent powder and preparation method thereof

A phosphor powder and co-doping technology is applied in the field of new functional materials to achieve the effects of wide adjustable range of parameters, high purity and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Dissolve 1.46g of bismuth nitrate pentahydrate in 30mL of ethylene glycol solution, and dissolve 0.49g of sodium tungstate in 30mL of dilute nitric acid solution with a concentration of 0.6mol / L; mix the above two solutions evenly, and use 2mol / L L sodium hydroxide adjusts the pH of the solution to 5;

[0037](2) Move to a hydrothermal reaction kettle, and place in a blast drying oven and heat to 180°C for hydrothermal treatment for 2 hours;

[0038] (3) Naturally cool to room temperature after taking it out, centrifuge the obtained product, wash with deionized water and absolute ethanol three times respectively, dry at 80° C. for 12 hours, and grind to obtain bismuth tungstate powder.

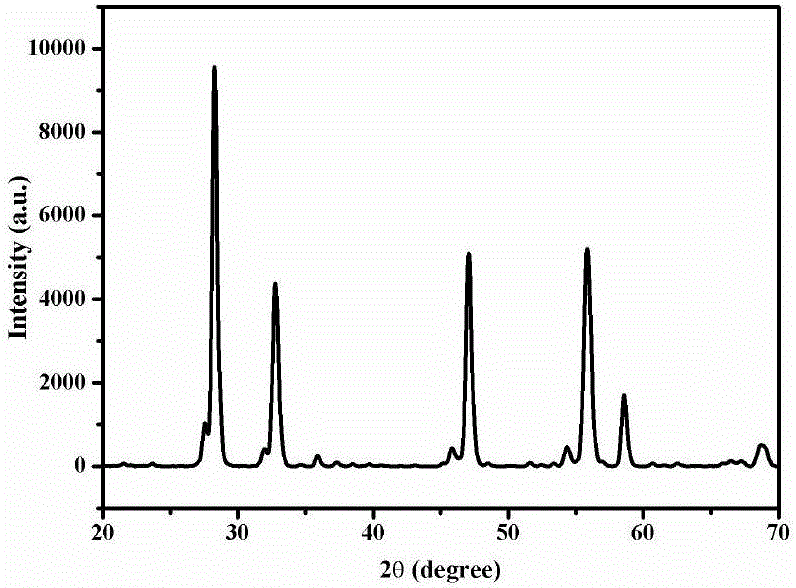

[0039] figure 1 It is the powder XRD pattern of bismuth tungstate. The position of each characteristic diffraction peak of the sample is consistent with the JCPDS card No.39-0256 standard card of the orthorhombic crystal system. It belongs to the orthorhombic crystal system. The sp...

Embodiment 2

[0041] (4) Dissolve 1.46g of bismuth nitrate pentahydrate in 30mL of ethylene glycol solution, and dissolve 0.49g of sodium tungstate in 30mL of dilute nitric acid solution with a concentration of 0.6mol / L; mix the above two solutions evenly;

[0042] (5) 0.0085g of holmium oxide and 0.0443g of ytterbium oxide were dissolved in nitric acid solution with a mass concentration of 20%, and then added dropwise to the above mixed solution, and the pH of the solution was adjusted to 5 with 2mol / L sodium hydroxide;

[0043] The suspension was moved to a hydrothermal reaction kettle, hydrothermally treated at 180°C for 2 hours, then cooled to room temperature, the obtained product was centrifuged, washed three times with deionized water and absolute ethanol, and dried at 80°C for 12 hours;

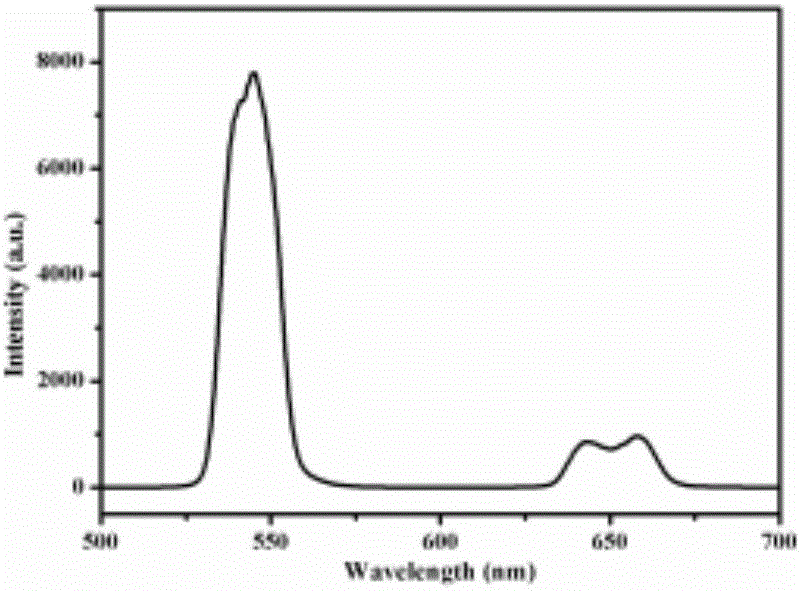

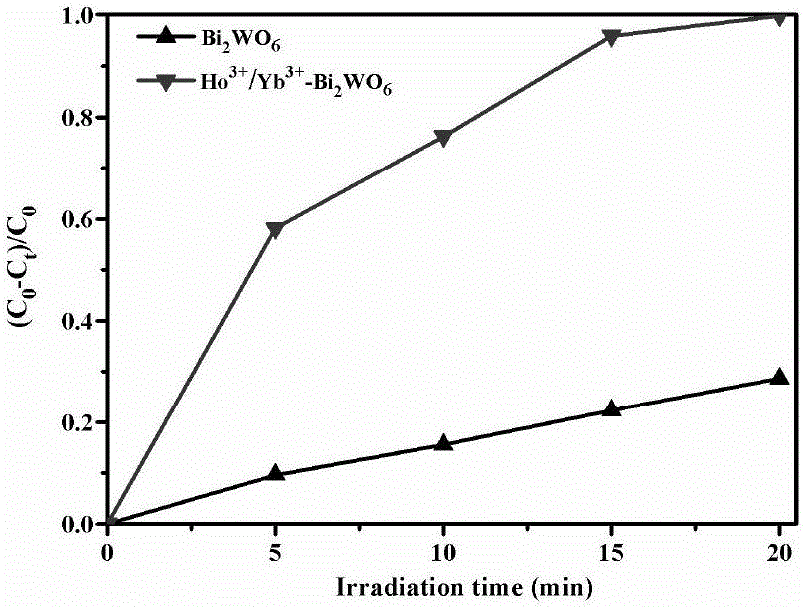

[0044] (1) The ground product was calcined and kept in a muffle furnace at 550°C for 4 hours, and then ground again to obtain holmium-ytterbium co-doped bismuth tungstate Bi 1.94 Ho 0.01 Yb 0.05 ...

Embodiment 3

[0047] (1) Dissolve 1.46g of bismuth nitrate pentahydrate in 30mL of ethylene glycol solution, and dissolve 0.49g of sodium tungstate in 30mL of dilute nitric acid solution with a concentration of 0.6mol / L; mix the above two solutions evenly;

[0048] (2) Dissolving 0.0085g of holmium oxide and 0.0443g of ytterbium oxide in a nitric acid solution with a mass concentration of 20%, then adding the above mixed solution dropwise, and adjusting the pH of the solution to 5 with 2mol / L sodium hydroxide;

[0049] (3) Move the suspension to a hydrothermal reaction kettle, hydrothermally treat it at 200°C for 2 hours, then cool to room temperature, centrifuge the obtained product, wash with deionized water and absolute ethanol three times, and dry at 80°C 12 hours;

[0050] (4) The ground product was calcined and kept in a muffle furnace at 600°C for 4 hours, and then ground again to obtain holmium-ytterbium co-doped bismuth tungstate Bi 1.94 Ho 0.01 Yb 0.05 WO 6 powder.

[0051] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com