Method for preparing silver-loaded titanate-zirconium phosphate composite nanometer material

A technology of composite nanomaterials, silver titanate phosphate, applied in botany equipment and methods, chemicals for biological control, animal repellants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 2 grams of potassium titanate powder into 100 milliliters of deionized water, and stir evenly. 6 ml of phosphoric acid was added, and the pH of the solution was adjusted to 2 with ammonia. Afterwards, 0.08 g of silver nitrate was added under light-shielding conditions, and stirred to dissolve. It was then stirred for 30 hours in the dark. At the same time, 0.8 g of zirconium oxychloride octahydrate was added into 20 ml of deionized water, and stirred to dissolve. After the stirring in the dark, the zirconium oxychloride solution was added to the former solution, and the stirring was continued in the dark for 8 hours. After stirring, the precipitate was washed with deionized water until the pH of the washing solution was neutral, and then dried. Afterwards, it was fired at 800 degrees for 2 hours to obtain the target silver-loaded titanate zirconium phosphate composite nanomaterial.

[0023] The obtained silver-loaded titanate zirconium phosphate composite nanoma...

Embodiment 2

[0025] Add 2 grams of sodium titanate powder into 100 milliliters of deionized water, and stir evenly. 5 ml of phosphoric acid was added, and the pH of the solution was adjusted to 3 with ammonia. Then add 0.04 g of silver nitrate and stir to dissolve. It was then stirred in the dark for 24 hours. At the same time, 1.0 g of zirconium nitrate pentahydrate was added to 30 ml of deionized water, and stirred to dissolve. After the stirring in the dark, the zirconium nitrate solution was added to the former solution, and the stirring was continued in the dark for 6 hours. After stirring, the precipitate was washed with deionized water until the pH of the washing solution was neutral, and then dried. Afterwards, it was fired at 600 degrees for 3 hours to obtain the target silver-loaded titanate zirconium phosphate composite nanomaterial.

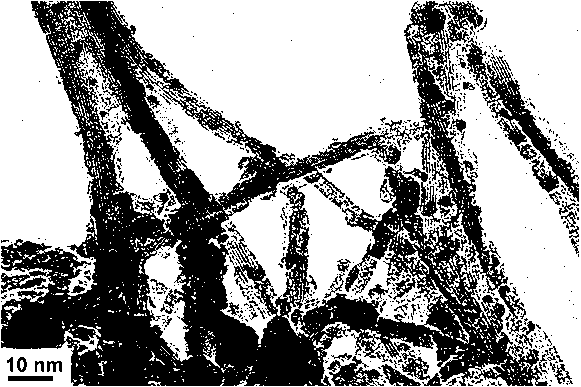

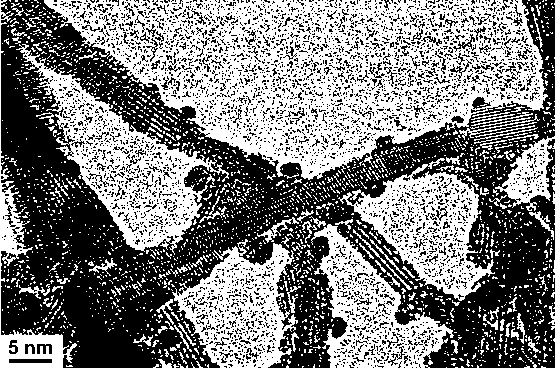

[0026] The obtained silver-loaded titanate zirconium phosphate composite nanomaterial has a dendritic or network morphology formed by stackin...

Embodiment 3

[0028] Add 5 grams of potassium titanate powder into 200 milliliters of deionized water, and stir evenly. 10 ml of phosphoric acid was added, and the pH of the solution was adjusted to 2 with aqueous ammonia. Afterwards, 0.2 g of silver nitrate was added under light-shielding conditions, and stirred to dissolve. It was then stirred for 36 hours in the dark. At the same time, 1.5 grams of zirconium carbonate was added to 30 milliliters of deionized water, and stirred to dissolve. After the stirring in the dark, the zirconium carbonate solution was added to the former solution, and the stirring was continued in the dark for 5 hours. After stirring, the precipitate was washed with deionized water until the pH of the washing solution was neutral, and then dried. Afterwards, it was fired at 900 degrees for 2 hours to obtain the target silver-loaded titanate zirconium phosphate composite nanomaterial.

[0029] The obtained silver-loaded titanate zirconium phosphate composite nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com