Preparation method for coating metal nanoparticles on surface of nano-titania

A technology of metal nanoparticles and nano-titanium dioxide, which is applied in the field of preparation of loaded metal nanoparticles, can solve problems such as poor surface dispersion of titanium dioxide, loaded metal nanoparticles, and large particle size of metal particles, achieving strong repeatability, stable performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 0.222g of copper nitrate hexahydrate, 3.124g of sodium nitrate and 0.1 milliliter of methanol were successively added to 65 milliliters of ammonia water with a mass fraction of 10%, stirring and dissolving completely; 8 milliliters of isopropyl titanate was directly added to the above-mentioned ammonia solution, and The isopropyl titanate is rapidly hydrolyzed while stirring vigorously to make it evenly mixed. Then the suspension was put into a Teflon-lined stainless steel autoclave and reacted at 443K for 72 hours. After the reaction, the precipitated product was washed with deionized water, and then vacuum-dried at 333K for 12 hours to obtain brookite-type titanium dioxide nanoparticles supported by copper nanoparticles.

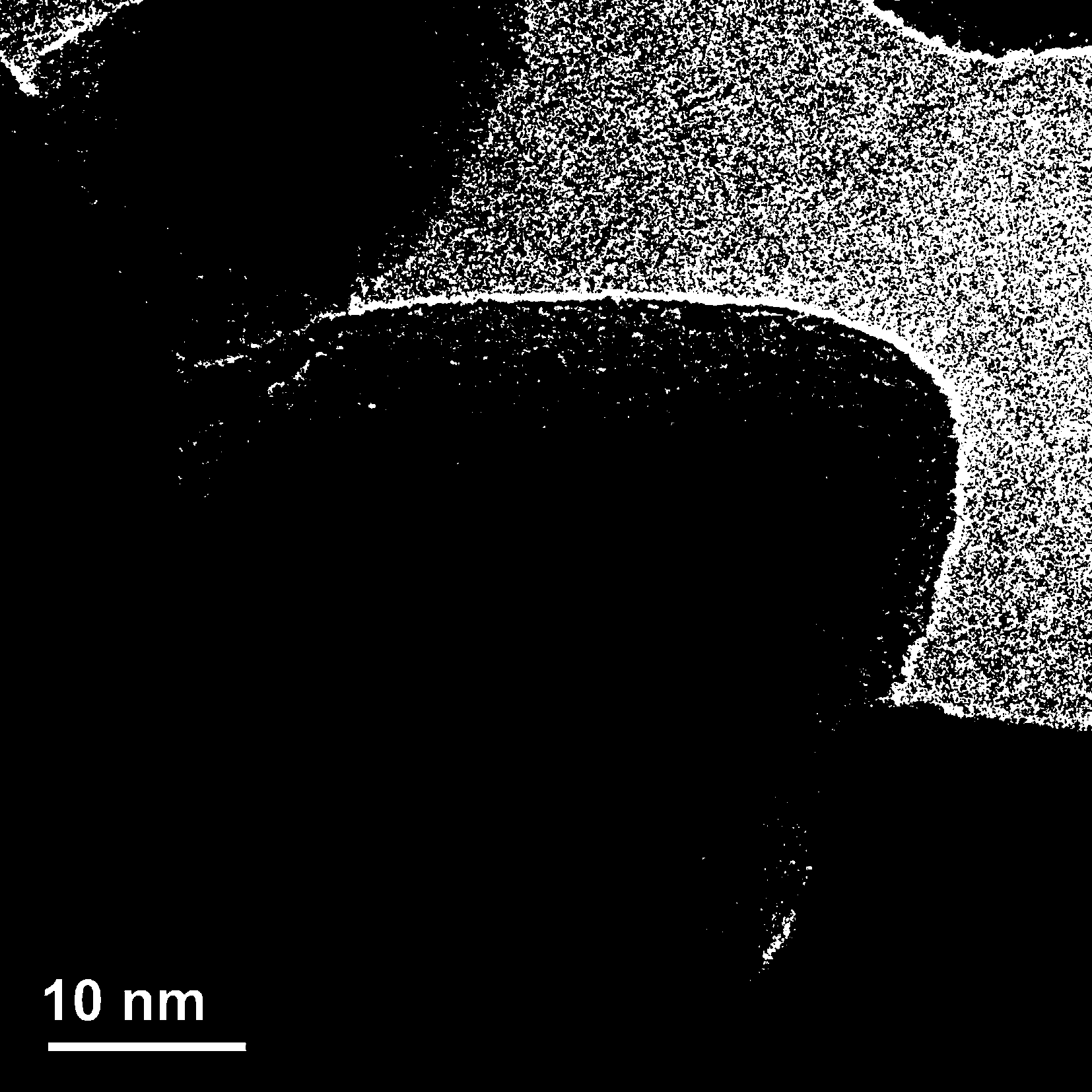

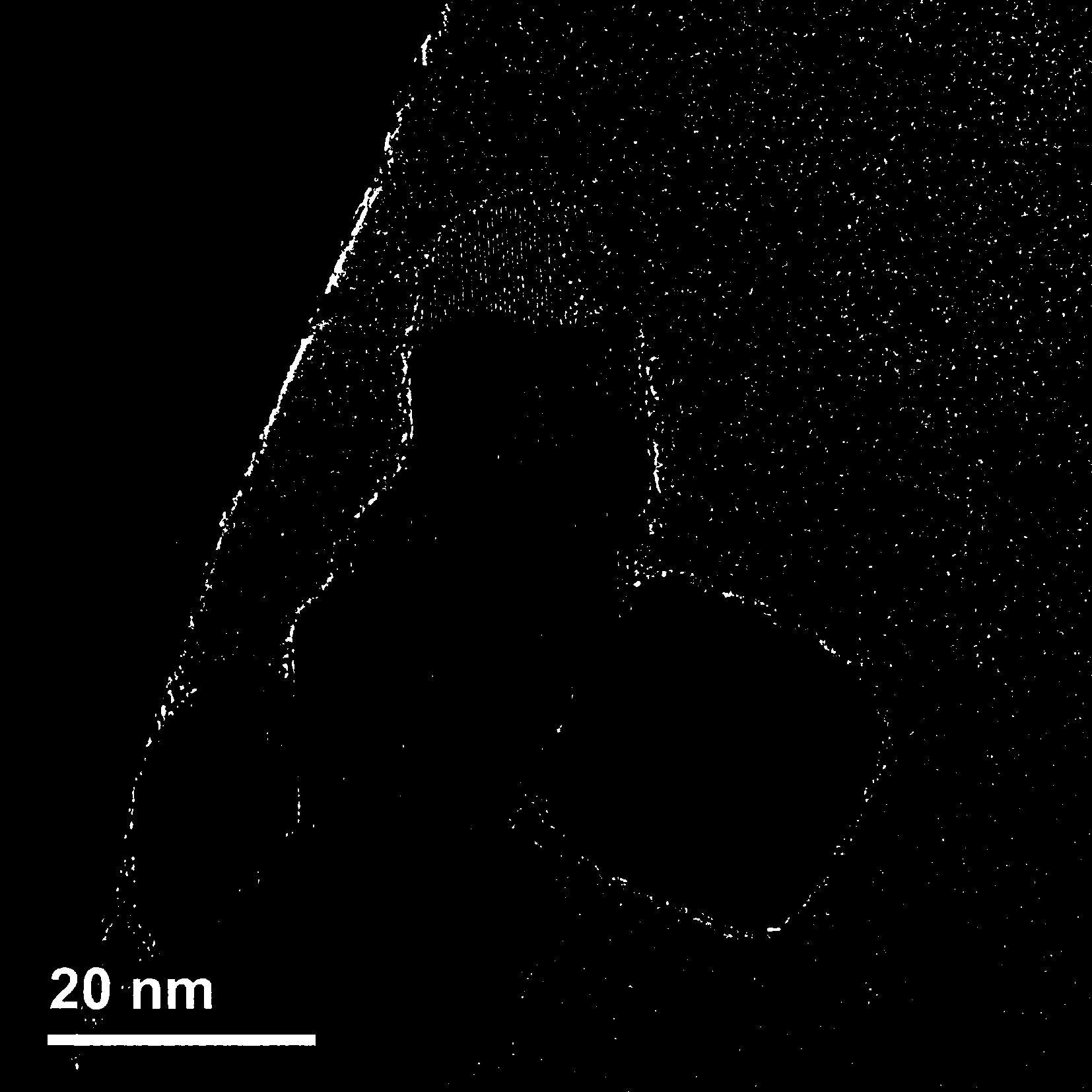

[0027] The prepared brookite-type titanium dioxide nano-rods are in the shape of a bunch of aggregated bouquets, the diameter of a single nano-rod is 40-50 nanometers, and the length is between 1000-2500 nanometers. The size of copper nanoparticles...

Embodiment 2

[0029] Add 0.218g nickel nitrate hexahydrate and 0.15 milliliters of ethanol to 50 milliliters of ammonia water with a mass fraction of 6% successively, stir and dissolve completely; directly add 6 milliliters of n-butyl titanate to the above-mentioned ammonia solution, Stir vigorously while rapidly hydrolyzing to make it evenly mixed. Then the suspension was put into a Teflon-lined stainless steel autoclave and reacted at 473 K for 12 h. After the reaction, the precipitated product was washed with deionized water, and then vacuum-dried at 333K for 6 hours to obtain anatase titanium dioxide nanoparticles supported by nickel nanoparticles.

[0030] The size of the prepared anatase titanium dioxide nanoparticles is about 30 nanometers. The size of nickel nanoparticles is about 2-4 nanometers, and they are evenly loaded on the surface of anatase titanium dioxide nanoparticles. The product purity is above 99%.

Embodiment 3

[0032] Add 0.465g of zinc nitrate hexahydrate and 0.3 ml of methanol to 62 ml of ammonia water with a mass fraction of 15% in turn, stir and dissolve completely; directly add 10 ml of isopropyl titanate to the above ammonia solution, Stir vigorously while rapidly hydrolyzing to make it evenly mixed. Then the suspension was put into a Teflon-lined stainless steel autoclave and reacted at 433K for 48 hours. After the reaction, the precipitated product was washed with deionized water, and then dried under normal pressure at 343K for 24 hours to obtain anatase titanium dioxide nanoparticles loaded with zinc nanoparticles.

[0033] The size of the prepared anatase titanium dioxide nanoparticles is about 20 nanometers. The size of zinc nanoparticles is about 1-2 nanometers, and they are evenly loaded on the surface of anatase titanium dioxide nanoparticles. The product purity is above 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com