Bismuth oxychloride powder and preparation method thereof

A bismuth oxychloride powder technology, applied in the field of bismuth oxychloride powder and its preparation, can solve the problems of reducing the specific surface area of bismuth oxychloride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 1.2 grams of bismuth nitrate pentahydrate into 0.8 milliliters of concentrated nitric acid, add 25 milliliters of deionized water after preliminary stirring, stir to dissolve and dilute, and record it as solution A. Another 10 milliliters of ammonium chloride solution with a substance concentration of 0.5 mol / liter was prepared, which was designated as solution B.

[0024] Add solution A dropwise to solution B, and stir while adding dropwise to form a uniform suspension. The pH of the solution was adjusted to approximately 7 with 15% ammonia water, and then the suspension was placed in a 50 ml stainless steel autoclave lined with polytetrafluoroethylene, and reacted at a temperature of 423K for 18 hours. After the reaction is finished, the precipitated product is washed with deionized water and dried to obtain bismuth oxychloride powder.

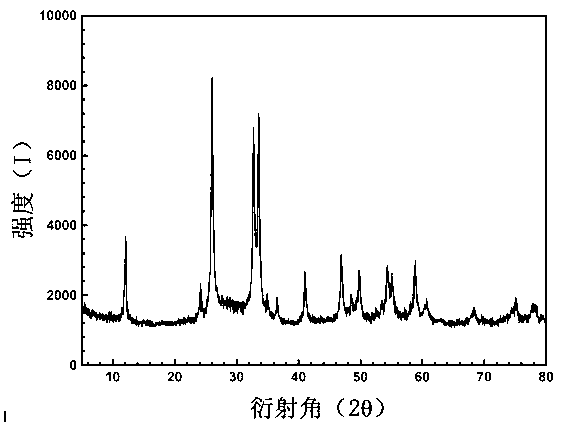

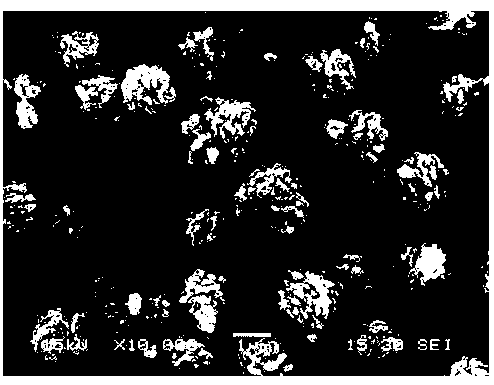

[0025] The prepared bismuth oxychloride (BiOCl) crystal form is consistent with the standard powder diffraction card (JCPDS: 85...

Embodiment 2

[0027] Add 2.0 g of bismuth nitrate pentahydrate to 1 ml of concentrated nitric acid, add 40 ml of deionized water after preliminary stirring, stir to dissolve and dilute, and record it as solution A. Another preparation of 20 milliliters of ammonium chloride solution with a substance concentration of 1 mol / liter is referred to as solution B.

[0028] Add solution A dropwise to solution B, and stir while adding dropwise to form a uniform suspension. Adjust the pH of the solution to about 7 with 25% ammonia water, then put the suspension into a 100 ml Teflon-lined stainless steel autoclave, and react at a temperature of 393K for 24 hours. After the reaction is finished, the precipitated product is washed with deionized water and dried to obtain bismuth oxychloride powder.

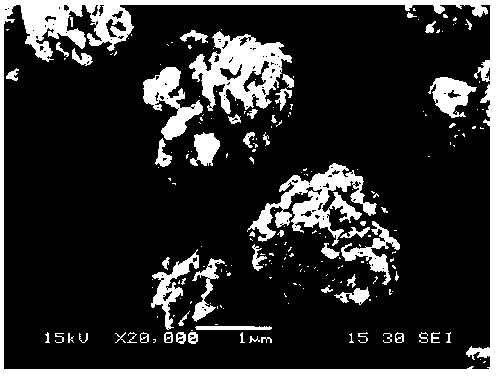

[0029] The prepared bismuth oxychloride (BiOCl) crystal form is consistent with the standard powder diffraction card (JCPDS: 85-0861), and the morphology is a flower-like cluster of nanocrystalline particle...

Embodiment 3

[0031] Add 5 grams of bismuth nitrate pentahydrate into 3 milliliters of concentrated nitric acid, add 120 milliliters of deionized water after preliminary stirring, stir to dissolve and dilute, and record it as solution A. Another preparation of 20 milliliters of ammonium chloride solution with a substance concentration of 1.5 mol / liter is referred to as solution B.

[0032] Add solution A dropwise to solution B, and stir while adding dropwise to form a uniform suspension. The pH of the solution was adjusted to approximately 7 with 20% ammonia water, and then the suspension was placed in a 200 ml stainless steel autoclave lined with polytetrafluoroethylene, and reacted at a temperature of 403K for 36 hours. After the reaction is finished, the precipitated product is washed with deionized water and dried to obtain bismuth oxychloride powder.

[0033] The prepared bismuth oxychloride (BiOCl) crystal form is consistent with the standard powder diffraction card (JCPDS: 85-0861),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com