Ethanol-sensitive Co-doped graded porous structure ZnO microspheres, preparation and applications thereof

An alcohol-sensitive, graded porous technology, applied in the direction of analyzing materials, material analysis by electromagnetic means, measuring devices, etc., can solve the problems of sensor interference, low sensitivity, false alarms, etc., to enhance sensitivity and response speed, and adjustable parameters. Wide range of effects with simple process and flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Prepare 40ml of 0.015M zinc nitrate solution;

[0032] Configuration 1.5*10 -4 M cobalt nitrate solution 40ml;

[0033] Configure 0.05M urea, 0.01M ascorbic acid mixed solution 40ml;

[0034] Slowly add the urea mixed solution into the zinc source solution, stir for 15 minutes, then add the cobalt nitrate solution, stir evenly, put it into a polytetrafluoroethylene-lined stainless steel autoclave, and conduct a hydrothermal reaction at 120 degrees Celsius for 10 hours.

[0035] After the reaction, the precipitated product was washed with deionized water until the pH of the washing solution was neutral, then dried, and calcined at 300 degrees Celsius for 1 hour to obtain the target object Co-doped hierarchical porous structure ZnO microspheres sensitive to ethanol .

Embodiment 2

[0037] Configure 40ml of 0.015M zinc sulfate solution;

[0038] Configuration 1.5*10 -4 M cobalt nitrate solution 40ml;

[0039] Configure 0.08M urea, 0.05M ascorbic acid mixed solution 40ml;

[0040] Slowly add the urea mixed solution into the zinc source solution, stir for 15 minutes, then add the cobalt nitrate solution, stir evenly, put it into a polytetrafluoroethylene-lined stainless steel autoclave, and conduct a hydrothermal reaction at 150 degrees Celsius for 6 hours.

[0041]After the reaction, the precipitated product was washed with deionized water until the pH of the washing solution was neutral, then dried, and calcined at 300 degrees Celsius for 1 hour to obtain the target object Co-doped hierarchical porous structure ZnO microspheres sensitive to ethanol .

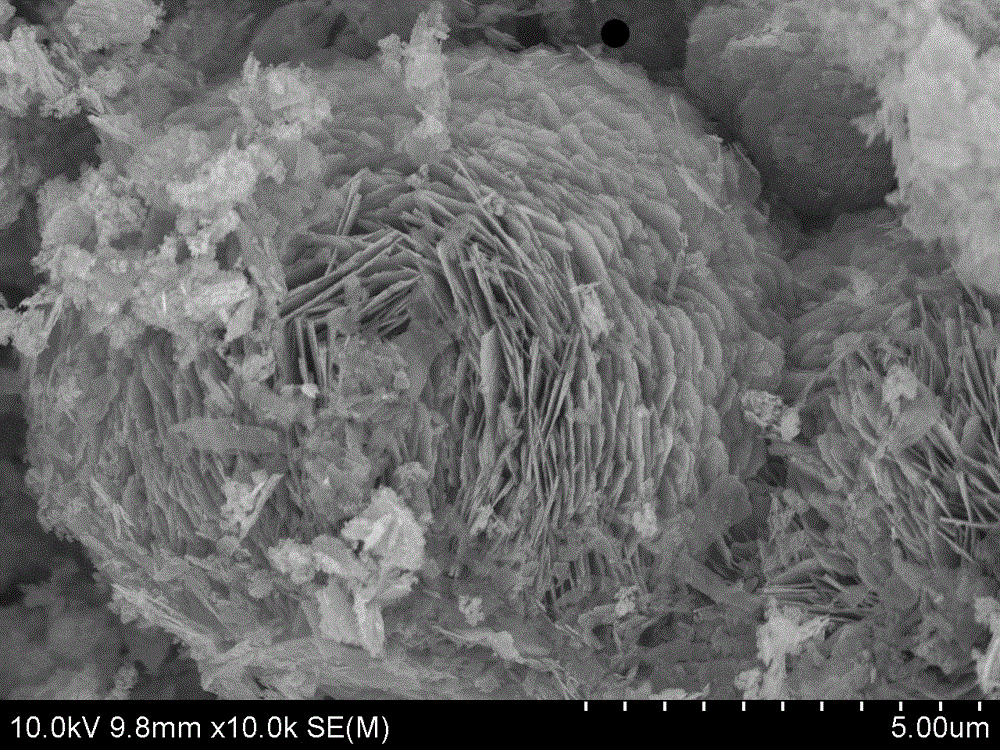

[0042] Depend on figure 1 It can be seen that the microspheres are first assembled from nanocrystals to form nanosheets, and these nanosheets self-assemble to form microspheres with a diameter of about ...

Embodiment 3

[0044] Prepare 40ml of 0.1M zinc chloride solution;

[0045] Configure 40ml of 0.003M cobalt nitrate solution;

[0046] Configure 0.3M urea, 0.08M ascorbic acid mixed solution 40ml;

[0047] Slowly add the urea mixed solution into the zinc source solution, stir for 15 minutes, then add the cobalt nitrate solution, stir evenly, put it into a polytetrafluoroethylene-lined stainless steel autoclave, and conduct a hydrothermal reaction at 180 degrees Celsius for 8 hours.

[0048] After the reaction, the precipitated product was washed with deionized water until the pH of the washing solution was neutral, then dried, and calcined at 300 degrees Celsius for 1 hour to obtain the target object Co-doped hierarchical porous structure ZnO microspheres sensitive to ethanol .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com