A preparation method for controlling the crystal form and morphology of titanium-based nanomaterial products

A technology of nanomaterials and products, which is applied in the field of preparation of inorganic nanomaterials to achieve the effects of strong repeatability, simple and easy preparation methods, and simple processes and procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 9 ml of n-tetrabutyl titanate into 65 ml of hydrochloric acid with a concentration of 3 mol / L, and stir evenly. Then the suspension was put into a Teflon-lined stainless steel autoclave and reacted at 453 K for 24 h. After the reaction, the precipitated product is washed with deionized water until the pH of the washing solution is neutral, and then dried to obtain the target titanium-based nanomaterial.

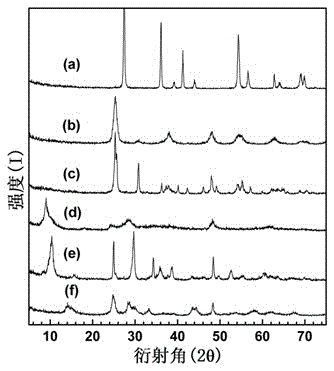

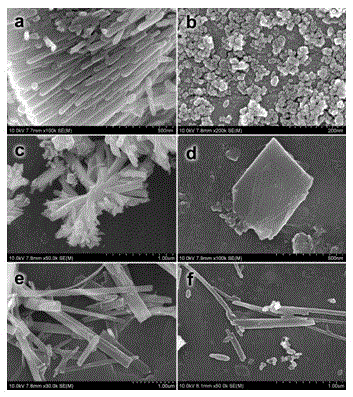

[0022] X-ray powder diffraction characterization results show that the prepared titanium-based nanomaterials are in the rutile crystal form; scanning electron microscope characterization results show that the prepared titanium-based nanomaterials are in the shape of nanorods, and the diameter of the nanorods is about 40 nanometers. Between 300 and 500 nanometers.

Embodiment 2

[0024] Add 15 ml of isopropyl titanate to 100 ml of hydrochloric acid with a concentration of 0.01 mol / L, and stir evenly. Then the suspension was put into a Teflon-lined stainless steel autoclave and reacted at 463 K for 36 h. After the reaction, the precipitated product is washed with deionized water until the pH of the washing solution is neutral, and then dried to obtain the target titanium-based nanomaterial.

[0025] X-ray powder diffraction characterization results show that the prepared titanium-based nanomaterials are in the anatase crystal form; scanning electron microscope characterization results show that the prepared titanium-based nanomaterials are monodisperse nanocrystals with a grain size of about 10 Nano or so.

Embodiment 3

[0027] Add 8 ml of tetraethyl titanate into 60 ml of sodium hydroxide solution with a concentration of 0.1 mol / L, and stir evenly. Then the suspension was put into a Teflon-lined stainless steel autoclave and reacted at 453 K for 48 h. After the reaction, the precipitated product is washed with deionized water until the pH of the washing solution is neutral, and then dried to obtain the target titanium-based nanomaterial.

[0028] X-ray powder diffraction characterization results show that the prepared titanium-based nanomaterials are in brookite crystal form; scanning electron microscope characterization results show that the prepared titanium-based nanomaterials are in the shape of nanoflowers. The nanoflower is composed of nanorods, the two ends of each nanoflower are petals with a radial multi-level structure, and the middle part of the nanoflower is a nanorod aggregate. The length (petal extension direction) of each nanoflower cluster is about 1 micron, but the diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com