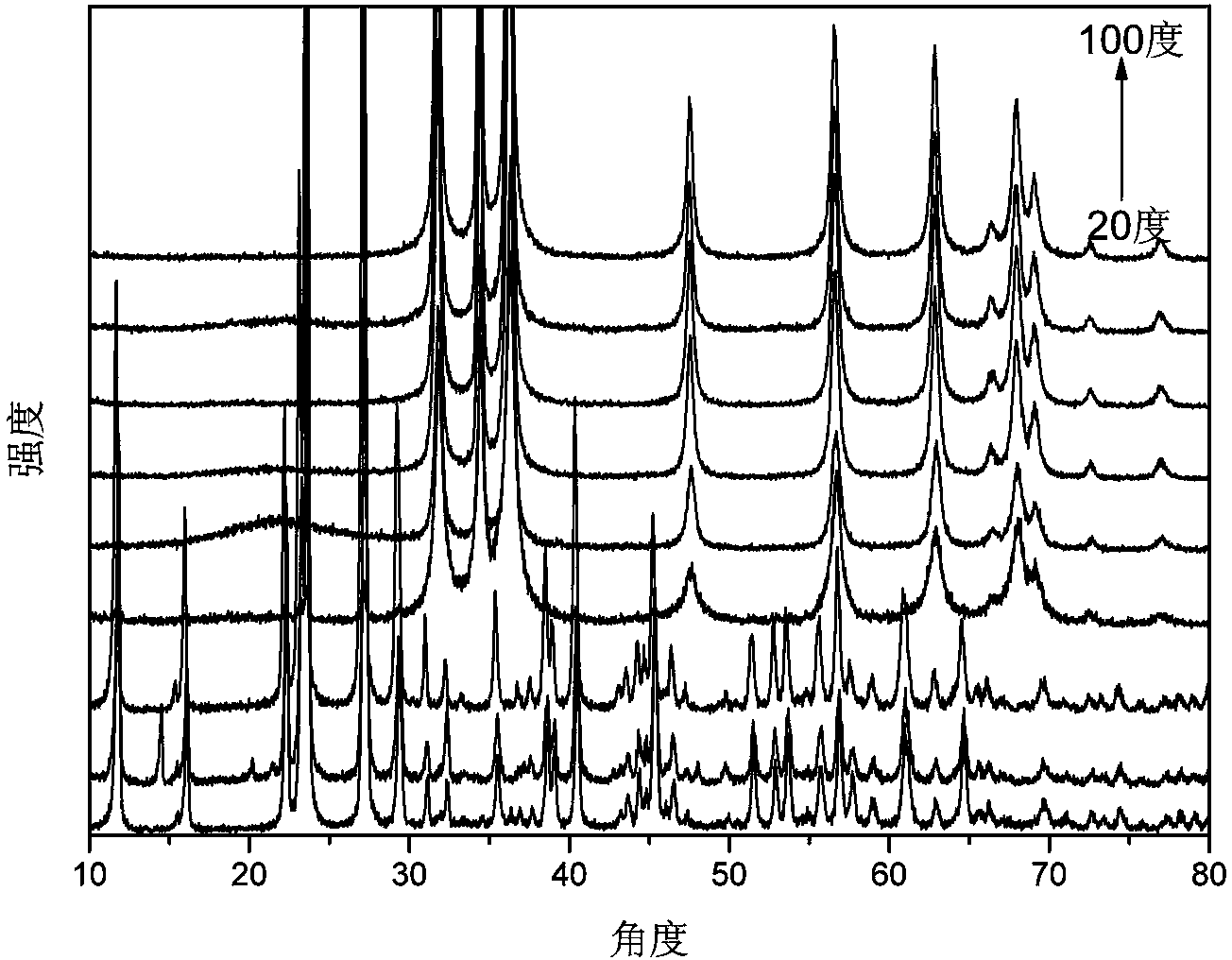

Low-temperature preparation method of morphology-controllable zinc oxide nano materials

A zinc oxide nano and morphology technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., to achieve the effect of simple and easy preparation method, wide adjustable range of parameters and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 0.01mol of cetyltrimethylammonium bromide and add it to 60ml of ethanol-water solution, stir rapidly at 20°C to mix evenly, then weigh 0.01mol of zinc nitrate and disperse it in the microemulsion; configure 0.1mol / Add L of sodium hydroxide solution into the zinc source microemulsion at a certain speed, and continue stirring at 20° C. for 20 minutes. After the reaction, the precipitated product was left to stand for 2 hours, washed and dried to obtain zinc hydroxide nanorods.

Embodiment 2

[0025] Weigh 0.01mol of sodium dodecylbenzenesulfonate and add it to 60ml of ethanol-water solution, stir rapidly at 30°C to mix evenly, then weigh 0.01mol of zinc nitrate and disperse it in the microemulsion; configure 0.1mol / L Ammonia solution was added to the zinc source microemulsion at a certain speed, and stirred continuously at 30° C. for 20 minutes. After the reaction was completed, it was left to stand for 2 hours, and the precipitated product was washed and dried.

[0026] X-ray powder diffraction characterization results show that the prepared material is zinc hydroxide; scanning electron microscope characterization results show that the prepared material is in the shape of nanorods, the diameter of nanorods is about 100 nanometers, and the length is between 3 and 5 microns. between.

Embodiment 3

[0028] Weigh 0.05mol of cetyltrimethylammonium bromide and add it to 60ml of ethanol-water solution, stir rapidly at 50°C to mix evenly, then weigh 0.05mol of zinc acetate and disperse it in the microemulsion; configure 0.3mol / L of ammonia solution was added to the zinc source microemulsion at a certain speed, and stirred continuously at 50° C. for 20 minutes. After the reaction was completed, it was left to stand for 2 hours, and the precipitated product was washed and dried.

[0029] X-ray powder diffraction characterization results show that the obtained material is zinc oxide in the wurtzite crystal form; scanning electron microscope characterization results show that the obtained material is a helical zinc oxide nanoflower, and the diameter of the nanorod is about 100 nanometers. The length is about 3 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com