Perovskite solar cell electronic transmission layer and preparation method thereof

An electron transport layer, solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., to achieve the effects of uniform morphology, simple process and process, and wide adjustable range of parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a method for preparing an electron transport layer of a perovskite solar cell, comprising the following steps:

[0037] (1) Cleaning steps for conductive glass: wash with soap solution for 15 minutes, rinse with pure water, ultrasonically clean with acetone for 15 minutes, ultrasonically for 15 minutes with ethanol, blow dry with nitrogen, and then clean with an oxygen plasma cleaner for 15 minutes;

[0038] (2) Weigh 0.297g zinc nitrate hexahydrate (a kind of zinc nitrate) and dissolve it in 100ml deionized water, stir at 65°C to form a zinc nitrate solution with a concentration of 0.01 mol / liter;

[0039] (3) At constant temperature, weigh 0.56g of hexamethylenetetramine and dissolve it in 100ml of deionized water to form a hexamethylenetetramine solution with a concentration of 0.04 mol / liter, and then add it dropwise to step (2) within 15 minutes in the resulting solution;

[0040] (4) the cleaned conductive glass is placed in the container...

Embodiment 2

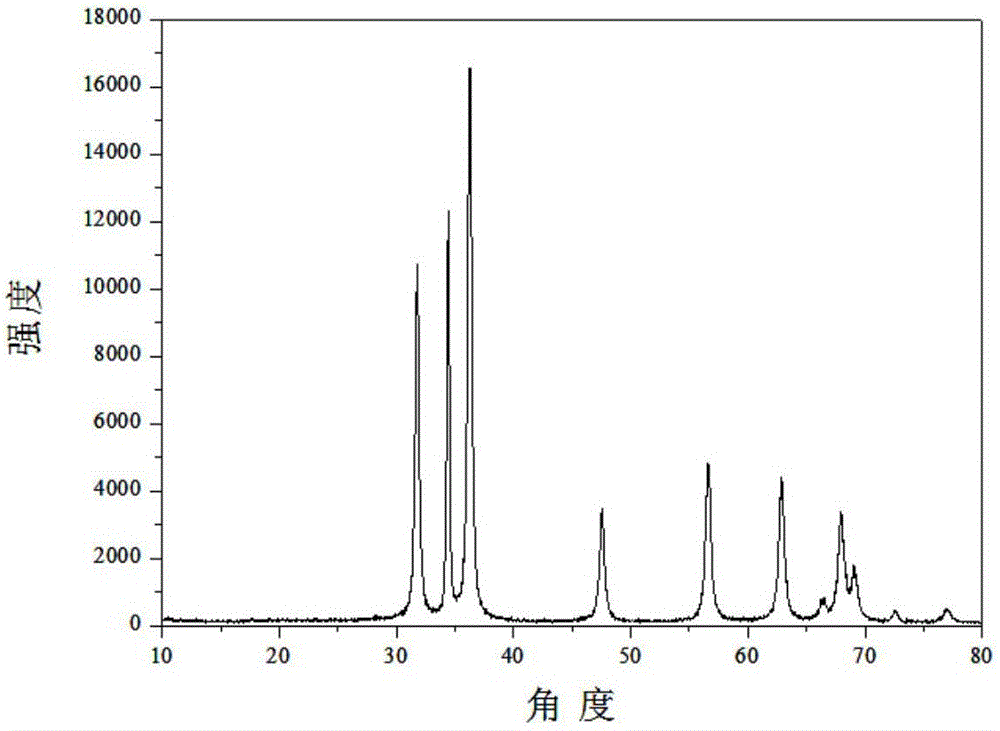

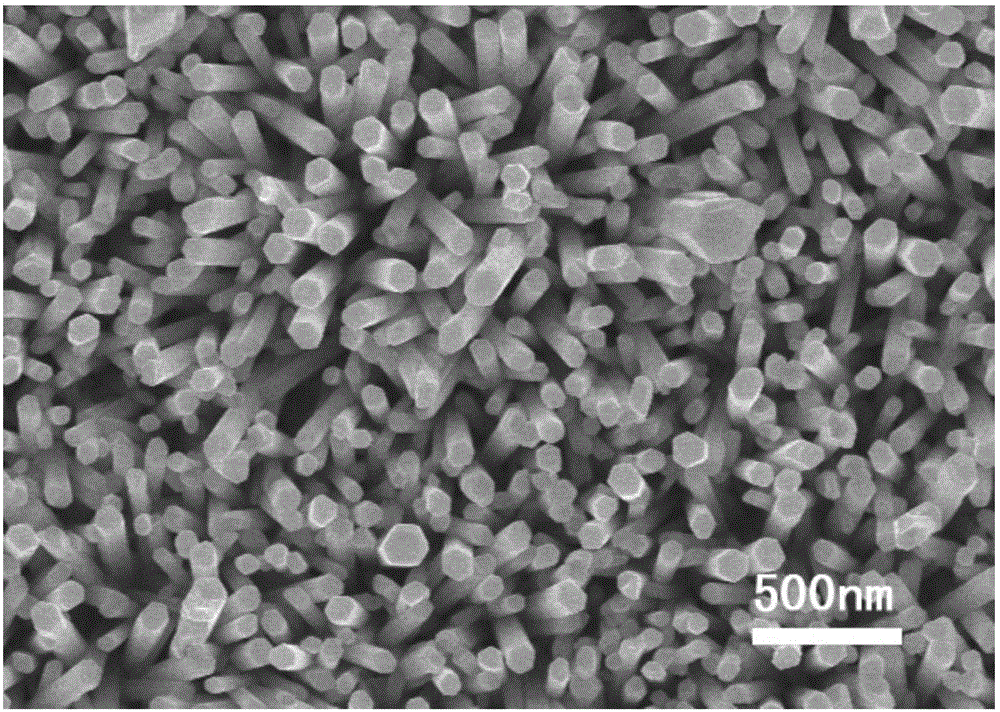

[0043] Such as figure 1 , figure 2 As shown, the present embodiment provides a method for preparing an electron transport layer of a perovskite solar cell, comprising the following steps:

[0044] (1) Cleaning steps of conductive glass: After rinsing with pure water, use acetone, isopropanol, and pure water in a ratio of 1:1:1 to sonicate for 15 minutes. After drying with nitrogen, put it into a solution of concentrated sulfuric acid / hydrogen peroxide 3:1. Hydrophilic treatment, followed by rinsing with pure water, ultrasonic cleaning with ethanol, and drying with nitrogen;

[0045] (2) Weigh 1.485g zinc nitrate hexahydrate and dissolve it in 100ml deionized water, stir at 65°C to form a zinc nitrate solution with a concentration of 0.05 mol / liter;

[0046] (3) Under constant temperature, weigh 0.12g sodium hydroxide and dissolve in 100ml deionized water to form a sodium hydroxide solution with a concentration of 0.3 mol / liter, then add dropwise in the solution obtained in ...

Embodiment 3

[0052] This embodiment provides a method for preparing an electron transport layer of a perovskite solar cell, comprising the following steps:

[0053] (1) Cleaning steps of conductive glass: wash with soap solution for 20 minutes, rinse with pure water, ultrasonically clean with acetone for 20 minutes, ultrasonically for 20 minutes with ethanol, blow dry with nitrogen, and then clean with an oxygen plasma cleaner for 20 minutes;

[0054] (2) Weigh 0.549g zinc acetate and dissolve it in 100ml deionized water, stir at 65°C to form a zinc acetate solution with a concentration of 0.03 mol / liter;

[0055] (3) At a constant temperature, weigh 0.842g potassium hydroxide and dissolve it in 100ml deionized water to form a potassium hydroxide solution with a concentration of 0.15 mol / liter, and then add it dropwise within 15 minutes;

[0056] (4) Put the cleaned conductive glass in the container containing the mixed solution obtained in step (3), lean the conductive glass against the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com