Potassium titanate nanowire and preparation method thereof

A nanowire, potassium titanate technology, applied in nanotechnology, chemical instruments and methods, titanium compounds, etc., can solve problems such as uneven morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

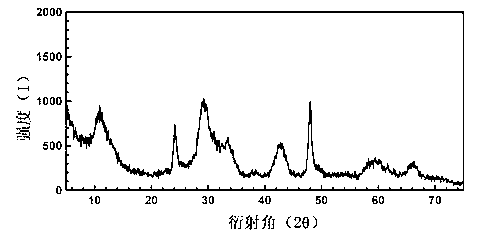

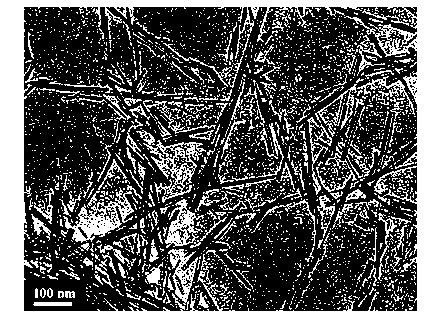

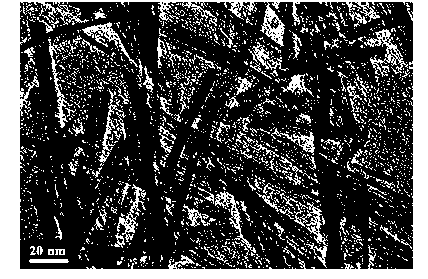

[0023] Add 15 milliliters of titanium sulfate to 130 milliliters of 3 mol / L potassium hydroxide alcoholic solution (volume percentage of ethanol is 20%), stir vigorously to make it evenly mixed while the titanium sulfate is rapidly hydrolyzed. Then the suspension was put into a 200 ml Teflon-lined stainless steel autoclave and reacted at 393K for 60 hours. After the reaction is finished, the precipitated product is washed with deionized water and dilute hydrochloric acid until the washing solution is close to neutral, and dried to obtain potassium titanate nanowires.

[0024] The crystal form of the obtained potassium titanate nanowires is consistent with the standard powder diffraction card (JCPDS: 41-1100). The diameter of the nanowires is about 6 nanometers, the length is between 100 and 800 nanometers, and the purity is more than 99%.

Embodiment 2

[0026] Add 8 ml of n-tetrabutyl titanate to 65 ml of potassium hydroxide alcoholic aqueous solution with a concentration of 5 mol / L (volume percentage of ethanol is 10%), stir vigorously while n-tetrabutyl titanate is rapidly hydrolyzed to make it evenly mixed . Then the suspension was put into a 100 ml Teflon-lined stainless steel autoclave and reacted at 423K for 48 hours. After the reaction is finished, the precipitated product is washed with deionized water and dilute hydrochloric acid until the washing solution is close to neutral, and dried to obtain potassium titanate nanowires.

[0027] The crystal form of the obtained potassium titanate nanowires is consistent with the standard powder diffraction card (JCPDS: 41-1100). The diameter of the nanowires is about 7 nanometers, the length is between 100 and 1000 nanometers, and the purity is over 99%.

Embodiment 3

[0029] Add 4 ml of isopropyl titanate to 35 ml of potassium hydroxide alcoholic aqueous solution with a concentration of 2 mol / L (the volume percentage of ethanol is 15%), stir vigorously to mix evenly while the isopropyl titanate is rapidly hydrolyzed . Then the suspension was put into a 50 ml Teflon-lined stainless steel autoclave and reacted at 413K for 48 hours. After the reaction is finished, the precipitated product is washed with deionized water and dilute hydrochloric acid until the washing solution is close to neutral, and dried to obtain potassium titanate nanowires.

[0030] The crystal form of the obtained potassium titanate nanowires is consistent with the standard powder diffraction card (JCPDS: 41-1100). The diameter of the nanowires is about 5 nanometers, the length is between 200 and 800 nanometers, and the purity is more than 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com