Method for preparing silver-loaded titanium oxide-zirconium phosphate composite nanometer material

A composite nanomaterial, zirconium phosphate technology, applied in the direction of titanium dioxide, chemical instruments and methods, botanical equipment and methods, etc., can solve the problems of low stability and easy discoloration of titanium dioxide nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 5 ml of isopropyl titanate to 50 ml of absolute ethanol, stir evenly, then add 3 ml of phosphoric acid, and adjust the pH to 2 with ammonia water. Then, under the condition of avoiding light, add 0.02 g of silver nitrate and stir to dissolve. Then, 5 milliliters of deionized water dissolved with 0.8 grams of zirconium oxychloride octahydrate was added dropwise to the former solution, and continued to stir in the dark for 5 hours. After the end, the precipitated product is washed with deionized water until the pH of the washing solution is neutral, and then dried. Calcining the dried powder material at 500° C. for 4 hours to obtain the target silver-loaded titanium oxide zirconium phosphate composite nanomaterial.

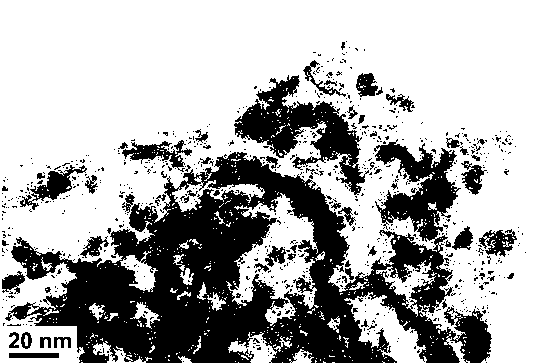

[0022] The obtained silver-loaded titanium oxide zirconium phosphate composite nano material is an aggregation state formed by stacking nano particles. The particle size of the titanium oxide zirconium phosphate composite nanoparticles is about 5-8 nano...

Embodiment 2

[0024] Add 10 ml of n-tetrabutyl titanate into 100 ml of absolute ethanol, stir evenly, then add 5 ml of phosphoric acid, and adjust the pH to 3 with ammonia water. Then, under the condition of avoiding light, add 0.08 g of silver nitrate and stir to dissolve. Then, 10 milliliters of deionized water dissolved with 1.2 grams of zirconium nitrate pentahydrate was added dropwise to the former solution, and continued to stir in the dark for 6 hours. After the end, the precipitated product is washed with deionized water until the pH of the washing solution is neutral, and then dried. Calcining the dried powder material at 600° C. for 3 hours to obtain the target silver-loaded titanium oxide zirconium phosphate composite nanomaterial.

[0025] The obtained silver-loaded titanium oxide zirconium phosphate composite nano material is an aggregation state formed by stacking nano particles. The particle size of the titanium oxide zirconium phosphate composite nanoparticles is about 6-9...

Embodiment 3

[0027] Add 15 ml of tetraethyl titanate to 200 ml of absolute ethanol, stir evenly, then add 10 ml of phosphoric acid, and adjust the pH to 4 with ammonia water. Then, under the condition of avoiding light, add 0.1 g of silver nitrate and stir to dissolve. Then, 15 milliliters of deionized water dissolved with 1.8 grams of zirconium carbonate was added dropwise to the former solution, and continued to stir in the dark for 8 hours. After the end, the precipitated product is washed with deionized water until the pH of the washing solution is neutral, and then dried. Calcining the dried powder material at 1000° C. for 2 hours to obtain the target silver-loaded titanium oxide zirconium phosphate composite nanomaterial.

[0028] The obtained silver-loaded titanium oxide zirconium phosphate composite nano material is an aggregation state formed by stacking nano particles. The particle size of the titanium oxide zirconium phosphate composite nanoparticles is about 9-12 nanometers. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com