Preparation method of silver-carrying layered titanate composite nano-grade material

A composite nanomaterial, layered titanate technology, applied in the fields of botanical equipment and methods, nanotechnology, nanotechnology, etc., can solve the problems of discoloration of antibacterial products, insufficient stability of silver antibacterial nanopowder, and easy deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

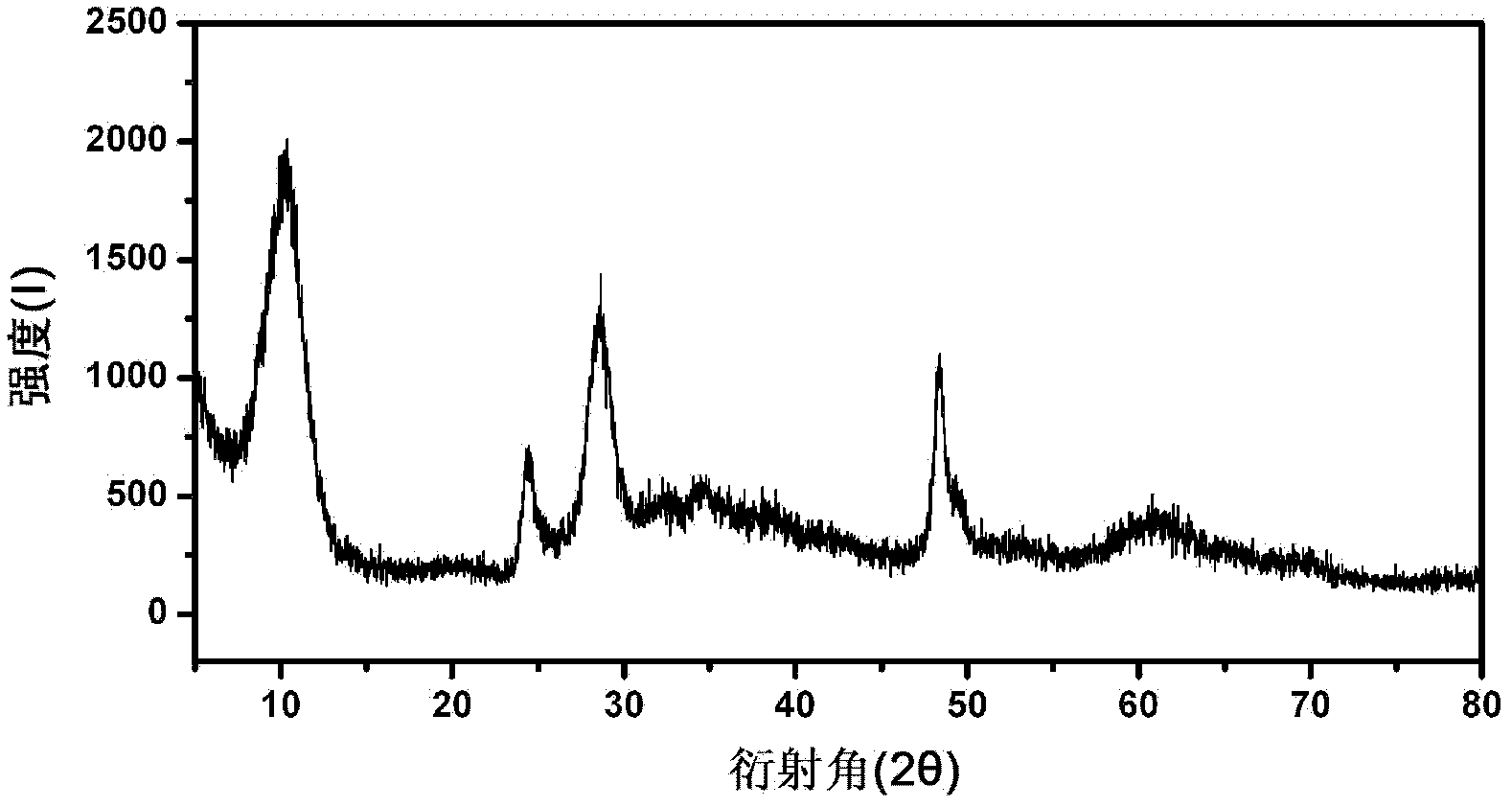

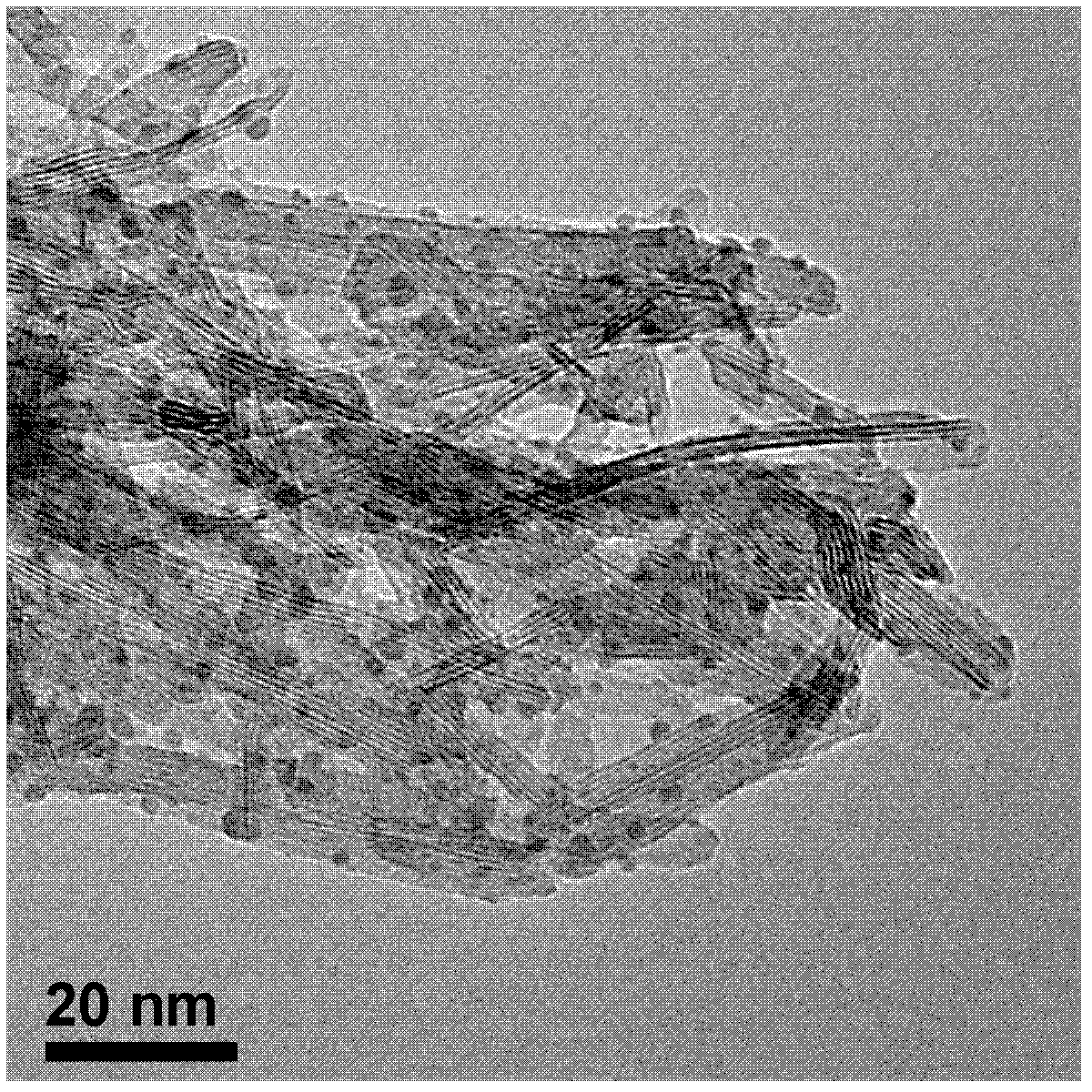

[0024] Add 2.0 g of anatase titanium dioxide nanoparticles into 10 mol / L sodium hydroxide aqueous solution, stir and disperse evenly. Then the suspension was put into a Teflon-lined stainless steel autoclave and reacted at 403 K for 24 h. After the reaction, the precipitated product was washed with deionized water, and then dried under normal pressure at 333K for 24 hours. A layered sodium titanate powder material is obtained.

[0025] Add the layered sodium titanate powder prepared in the previous step into 100 ml of deionized water, and stir evenly. Silver nitrate and 3 mL of ammonia were added to another 50 mL of deionized water and stirred to dissolve. The percentage of added silver element mass to titanium dioxide mass is 5%. The dilute ammonia solution of silver nitrate was added to the layered sodium titanate suspension, stirred for 12 hours, suction filtered, and then washed once with deionized water. The washed powder material was dried under normal pressure at 33...

Embodiment 2

[0027] Add 8 ml of n-tetrabutyl titanate into 1 mol / L sodium hydroxide aqueous solution, stir and disperse evenly. Then the suspension was put into a Teflon-lined stainless steel autoclave and reacted at 453 K for 24 h. After the reaction, the precipitated product was washed with deionized water, and then dried under normal pressure at 333K for 24 hours. A layered sodium titanate powder material is obtained.

[0028] Add the layered sodium titanate powder prepared in the previous step into 100 ml of deionized water, and stir evenly. Silver nitrate and 2 mL of ammonia were added to another 50 mL of deionized water and stirred to dissolve. The percentage of the added silver element mass to the mass equivalent of titanium dioxide is 3%, and the mass equivalent of titanium dioxide is converted by the raw material n-tetrabutyl titanate. Then, the dilute ammonia solution of silver nitrate was added to the layered sodium titanate suspension, stirred for 12 hours, and then filtered...

Embodiment 3

[0030] Add 5 ml of isopropyl titanate into 2 mol / L sodium hydroxide aqueous solution, stir and disperse evenly. Then the suspension was put into a Teflon-lined stainless steel autoclave and reacted at 423 K for 12 h. After the reaction, the precipitated product was washed with deionized water, and then dried under normal pressure at 333K for 24 hours. A layered sodium titanate powder material is obtained.

[0031] Add the layered sodium titanate powder prepared in the previous step into 100 ml of deionized water, and stir evenly. Silver nitrate and 3 mL of ammonia were added to another 50 mL of deionized water and stirred to dissolve. The percentage of the added silver element mass to the mass equivalent of titanium dioxide is 3%, and the mass equivalent of titanium dioxide is converted by the raw material isopropyl titanate. Then, the dilute ammonia solution of silver nitrate was added to the layered sodium titanate suspension, stirred for 12 hours, and then filtered with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com