A kind of preparation method of sheet graphene single/multi-loaded noble metal nanoparticles

A technology of flake graphite and nano-particles, which is applied in the field of preparation of inorganic nano-materials to achieve the effects of low cost, strong repeatability and wide adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

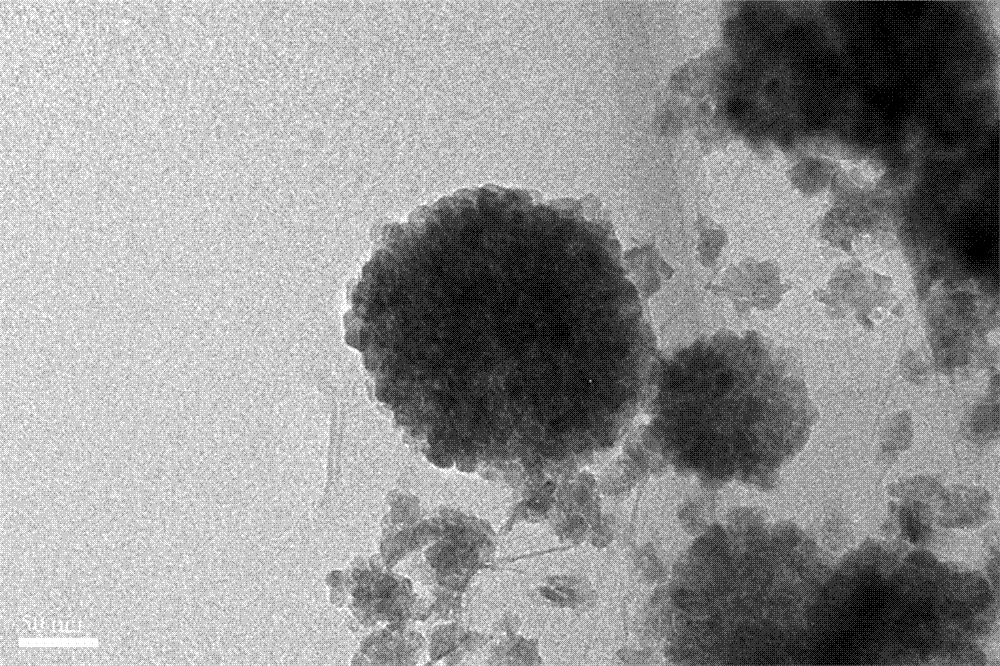

[0015] 100 mg graphene oxide was ultrasonically dispersed in 100 ml water to form a stable suspension. Then add 30ml of chloroauric acid solution with a concentration of 0.5mmol / L, and stir rapidly so that the above-mentioned solutions are mixed evenly. After adding 4 g of ascorbic acid as a reducing agent, the solution was transferred to a 200 ml beaker for 5 hours in an ultrasonic constant temperature water bath. After the water bath is finished, the precipitated product is dried to obtain a composite material of sheet-like graphene supported gold nanoparticles.

[0016] Scanning electron microscope characterization results (eg figure 1 ) shows that the gold nanoparticles obtained by reduction are in the shape of microspheres with a diameter of about 100nm, and the dispersion of gold nanoparticles is good.

Embodiment 2

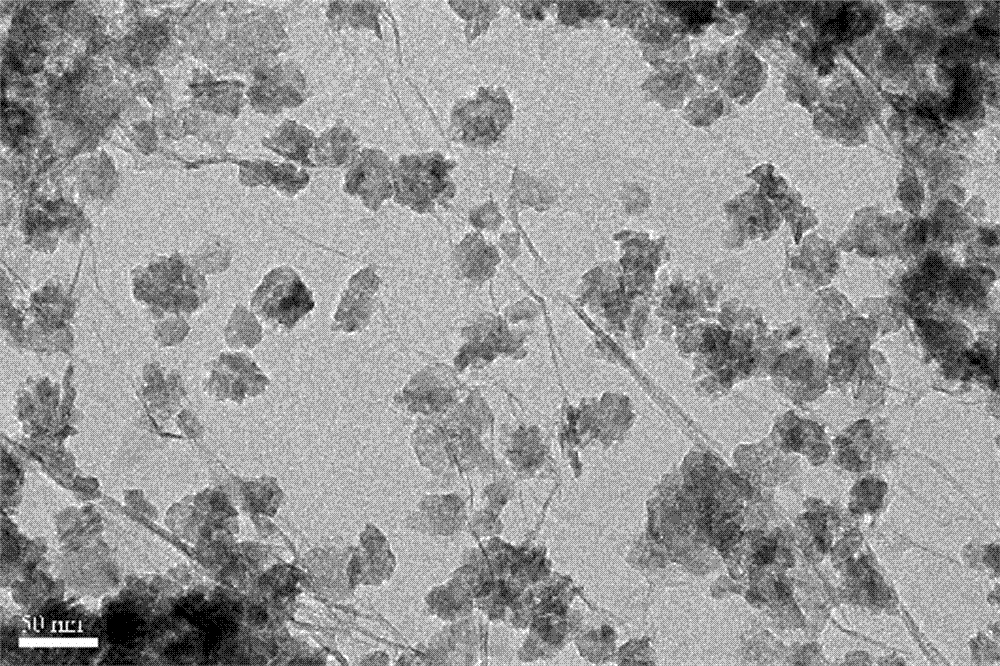

[0018] 140 mg graphene oxide was ultrasonically dispersed in 100 ml water to form a stable suspension. Then add 5ml of silver-ammonia solution with a concentration of 2mmol / L, and stir rapidly so that the above-mentioned solution is mixed evenly. After adding 3g of sodium borohydride as a reducing agent, the solution was transferred to a 200ml beaker and subjected to an ultrasonic constant temperature water bath for 2 hours. After the water bath is finished, the precipitated product is dried to obtain a composite material of sheet-like graphene loaded with silver nanoparticles.

[0019] Scanning electron microscope characterization results (eg figure 2 ) showed that the reduced silver nanoparticles were irregular, and some silver nanoparticles were agglomerated, with a diameter of about 50-80nm.

Embodiment 3

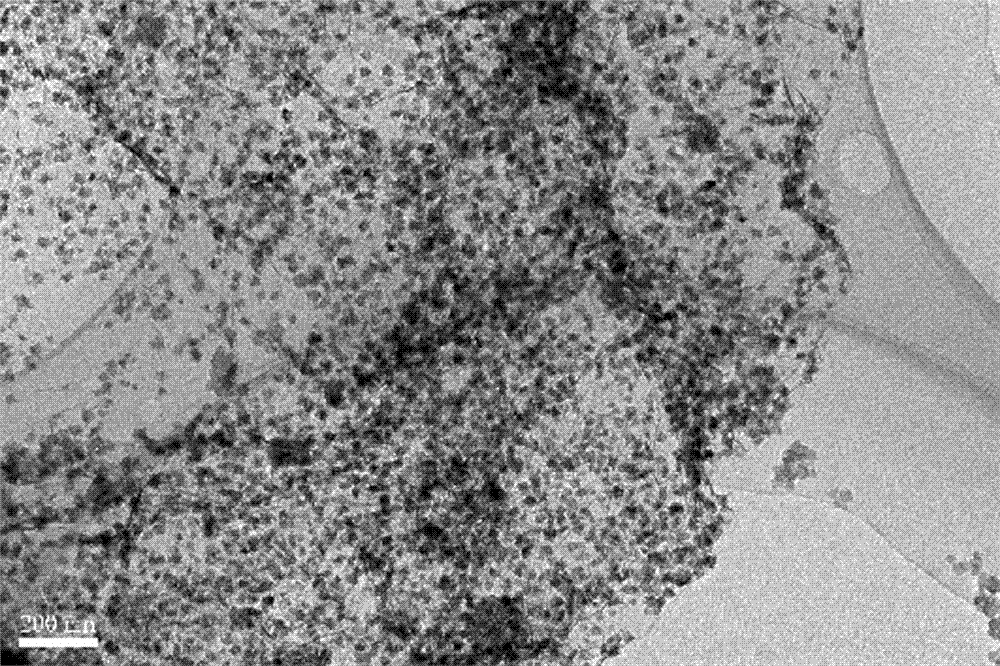

[0021] 80 mg graphene oxide was ultrasonically dispersed in 100 ml water to form a stable suspension. Then add 20 ml of palladium acetate solution with a concentration of 1 mmol / L, and stir rapidly so that the above-mentioned solutions are mixed evenly. After adding 6g of ammonium citrate as a reducing agent, the solution was transferred to a 200ml beaker for 3 hours in an ultrasonic constant temperature water bath. After the water bath is finished, the precipitated product is dried to obtain a composite material of sheet-like graphene-loaded palladium nanoparticles.

[0022] Scanning electron microscope characterization results ( image 3 ) shows that the palladium nanoparticles obtained by reduction are in the shape of microspheres, and are very uniformly dispersed on the surface of graphene, evenly distributed, and the particle size is relatively uniform, about 70-100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com