Process for preparing needle-like bismuth oxide powder

A preparation process and technology of bismuth oxide, applied in inorganic chemistry, bismuth compounds, chemical instruments and methods, etc., can solve the problems of nitrogen oxide gas environmental pollution and high cost, and achieve a wide adjustable range of parameters, low production cost, and repeatability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described further below by embodiment, and its purpose is only to better understand content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

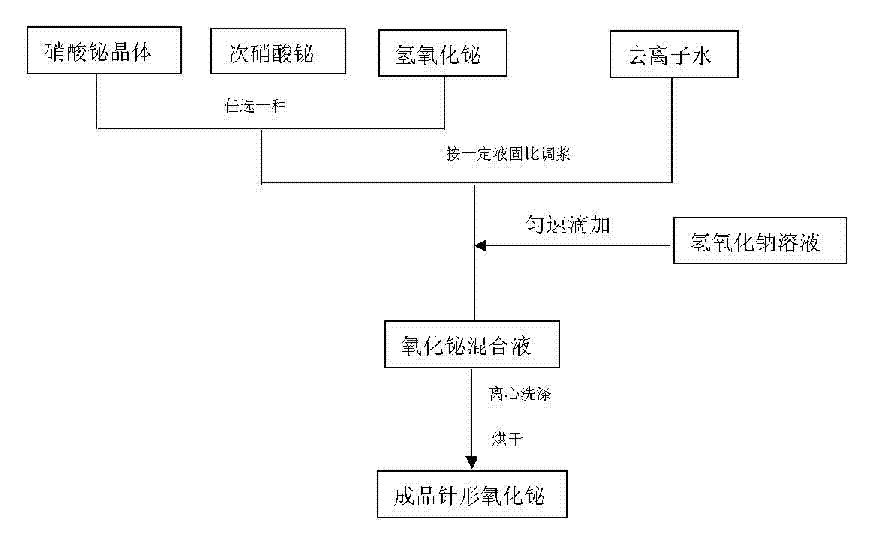

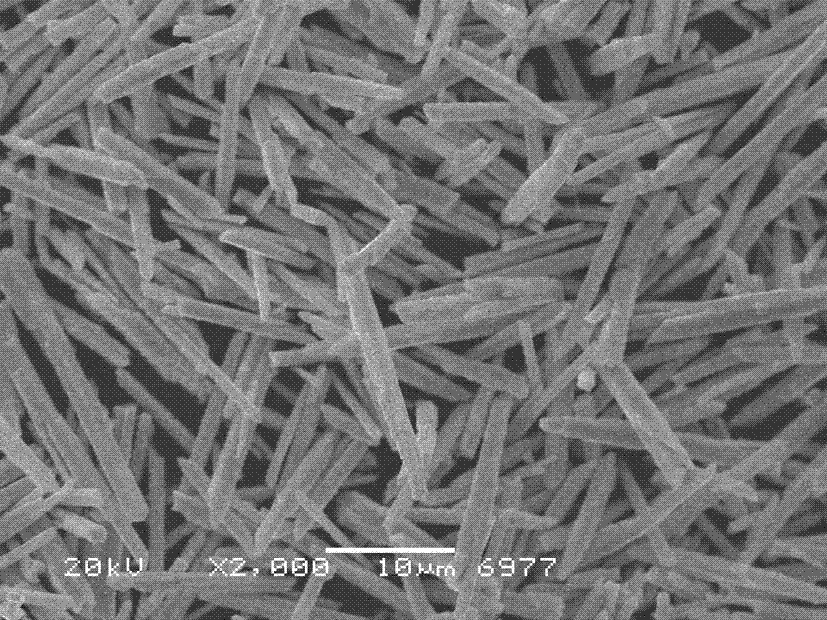

[0017] attached figure 1 In order to be shown as a preparation process of acicular bismuth oxide powder, the steps are as follows:

[0018] (1) Add bismuth nitrate crystals into deionized water to make slurry, and stir with a stirrer; control the solid-liquid mass volume ratio = 1:2g / ml; and heat to 70°C under the stirring condition of 280r / min, and keep the temperature constant;

[0019] (2) Prepare a sodium hydroxide solution with a concentration of 7mol / L; in order to control the purity, the prepared sodium hydroxide raw material is selected from caustic soda;

[0020] (3) Add the sodium hydroxide solution prepared in step (2) into the prepared slurry in step (1) dropwise at a constant speed, and control the stirrer to keep stirring a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com