Preparation method of stratified molybdenum disulfide nano material

A technology of molybdenum disulfide and nanomaterials, which is applied in the direction of molybdenum sulfide, nanotechnology, nanotechnology, etc., can solve the problems of limiting production and achieve the effects of low risk, high stripping rate and good physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Weigh 100g of molybdenum disulfide block raw material, add it to a 1L beaker, pour 1L of stripping solvent N-methylpyrrolidone (NMP), and make a molybdenum disulfide dispersion with a concentration of 100g / L.

[0033] Among them, the choice of stripping solvent is based on the difference between its surface tension and the surface tension of molybdenum disulfide. The smaller the difference, the more it can achieve the purpose of stripping single-layer and few-layer molybdenum disulfide nanosheets. Therefore, the surface tension range of the stripping solvent is required to be within 30-50mJ / m measured at 25°C 2 . The surface tension of the N-methylpyrrolidone of the present embodiment is 40mJ / m 2 (25°C), very suitable for the application of the present invention.

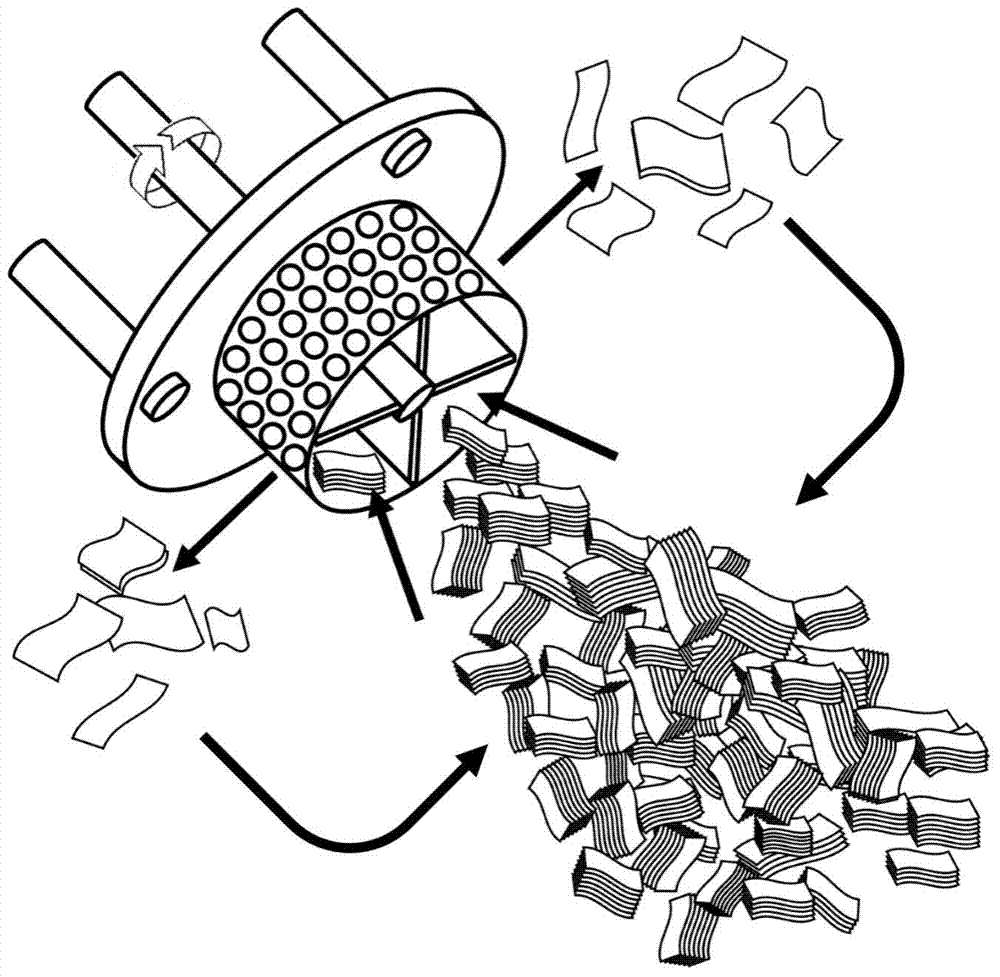

[0034] (2) Put the shearing head of the high-shear emulsifier into the molybdenum disulfide dispersion, gradually adjust the rotor speed to 1000rpm, and carry out hydraulic shearing treatment on the mol...

Embodiment 2

[0038] (1) Weigh 1g of molybdenum disulfide block raw material, add it to a 1L beaker, pour 1L of stripping solvent dimethyl sulfoxide (DMSO), the surface tension is about 43.6mJ / m 2 (25°C) to prepare a molybdenum disulfide dispersion with a concentration of 1g / L.

[0039](2) Put the shearing head of the high-shear emulsifier into the molybdenum disulfide dispersion, gradually adjust the rotor speed to 7500rpm, and carry out hydraulic shearing treatment on the molybdenum disulfide for 60 minutes. During the shearing process, The dispersion liquid was kept at 20°C.

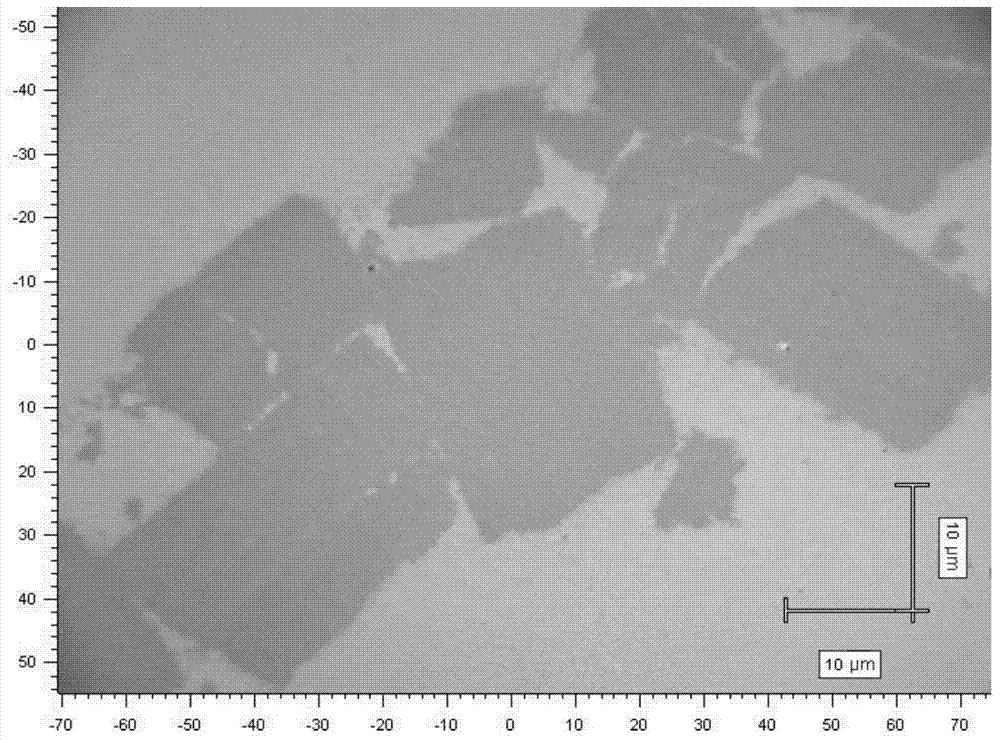

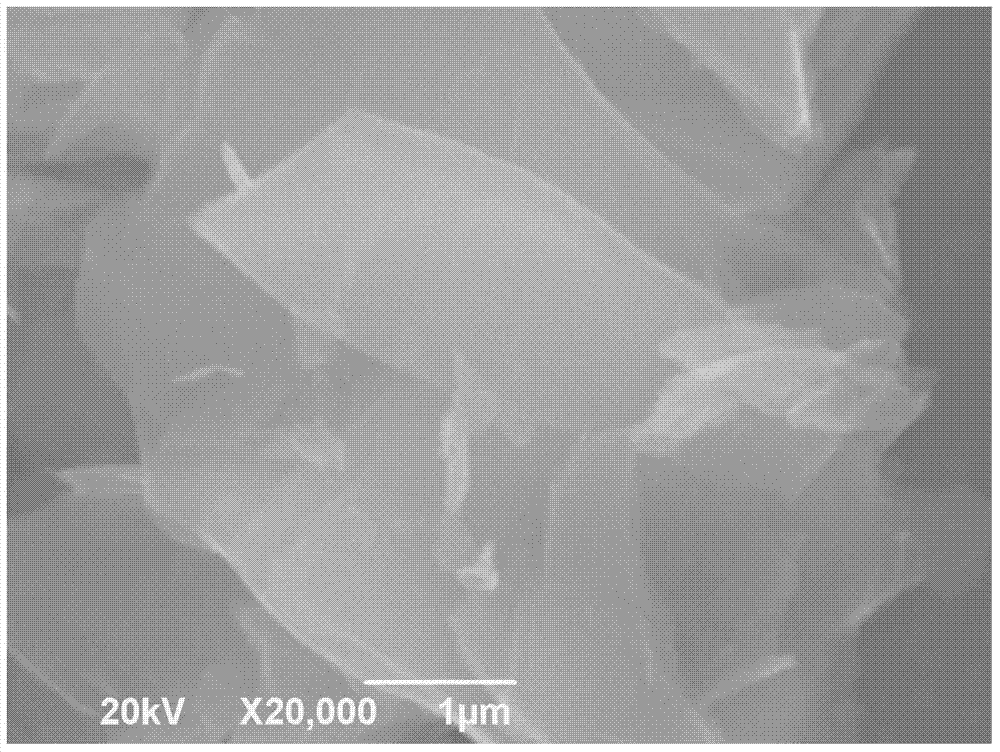

[0040] (3) Centrifuge the molybdenum disulfide dispersion after hydraulic shearing, the centrifugal speed is 2000rpm, and the centrifugation time is 120min. After centrifugation, the unstripped molybdenum disulfide precipitate was removed, and the upper suspension was collected for filtration. The filter membrane was a polytetrafluoroethylene membrane (PTFE) with a diameter of 50 mm and a pore size of 0.22 μm, whi...

Embodiment 3

[0043] (1) Weigh 10g of molybdenum disulfide block raw material, add it to a 1L beaker, pour N,N-dimethylformamide (DMF), the surface tension is about 37mJ / m 2 (25°C) to prepare a molybdenum disulfide dispersion with a concentration of 10g / L.

[0044] (2) Put the shearing head of the high-shear emulsifier into the molybdenum disulfide dispersion, gradually adjust the rotor speed to 4500rpm, and carry out hydraulic shearing treatment on the molybdenum disulfide for 50 minutes. During the shearing process, The dispersion liquid was kept at 30°C.

[0045] (3) Centrifuge the molybdenum disulfide dispersion liquid after hydraulic shearing, the centrifugation speed is 1000rpm, and the centrifugation time is 60min. After centrifugation, remove the unstripped molybdenum disulfide precipitate, collect the upper suspension and filter it. The filter membrane is a polytetrafluoroethylene membrane (PTFE) with a diameter of 50 mm and a pore size of 0.22 μm, which is used to remove the stri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com