Circulating airflow drying device for pilot plant test

A technology of circulating airflow and drying device, which is applied in the directions of drying gas arrangement, drying solid materials, drying, etc., can solve the problems of limited application of installation height, sticking to the wall, short drying time, etc., to improve the overall efficiency of separation and long service life. , the effect of improving fitness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

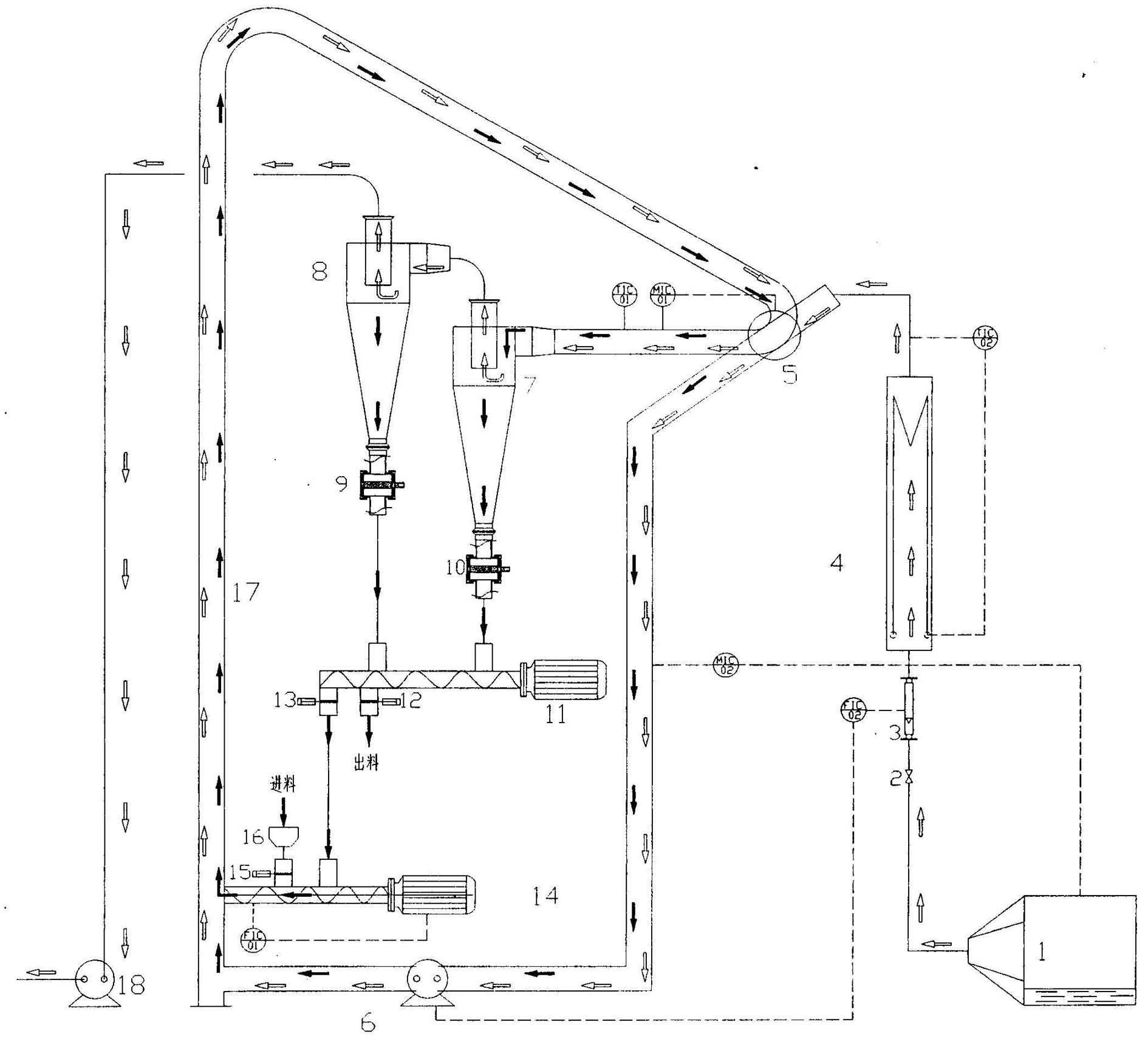

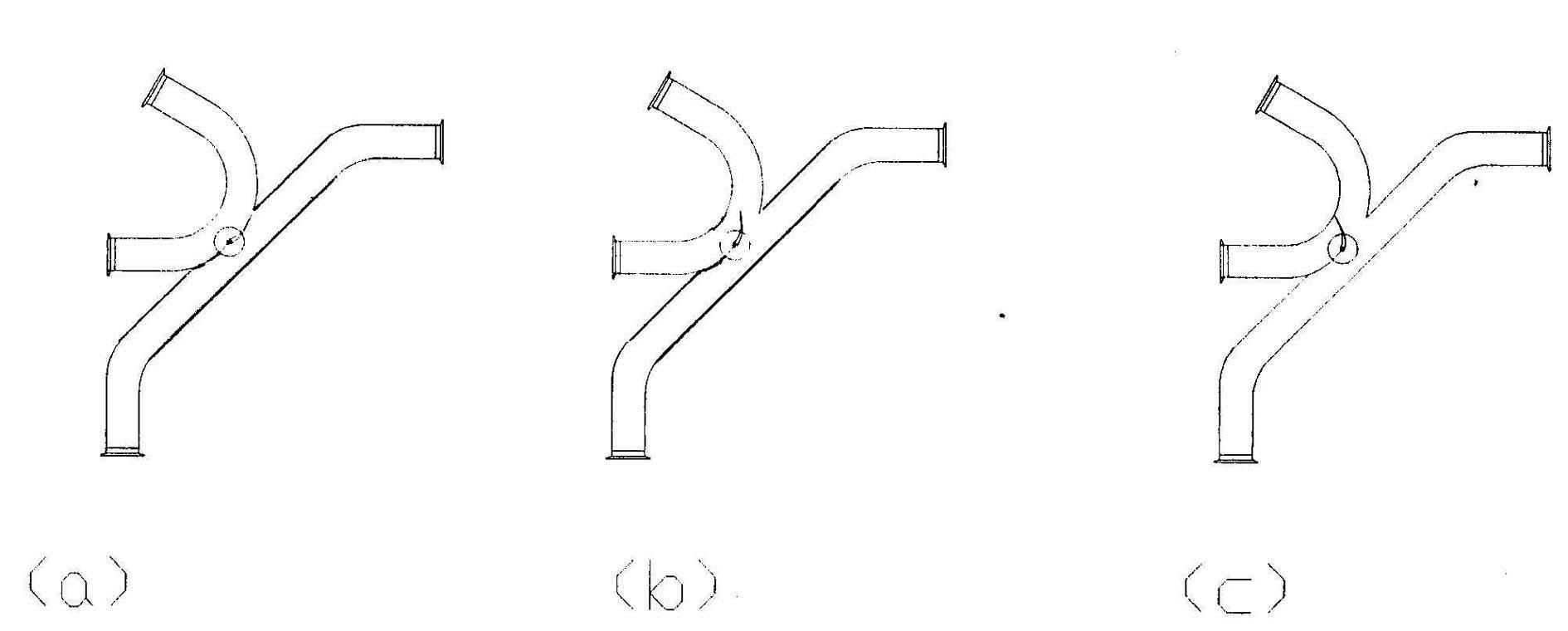

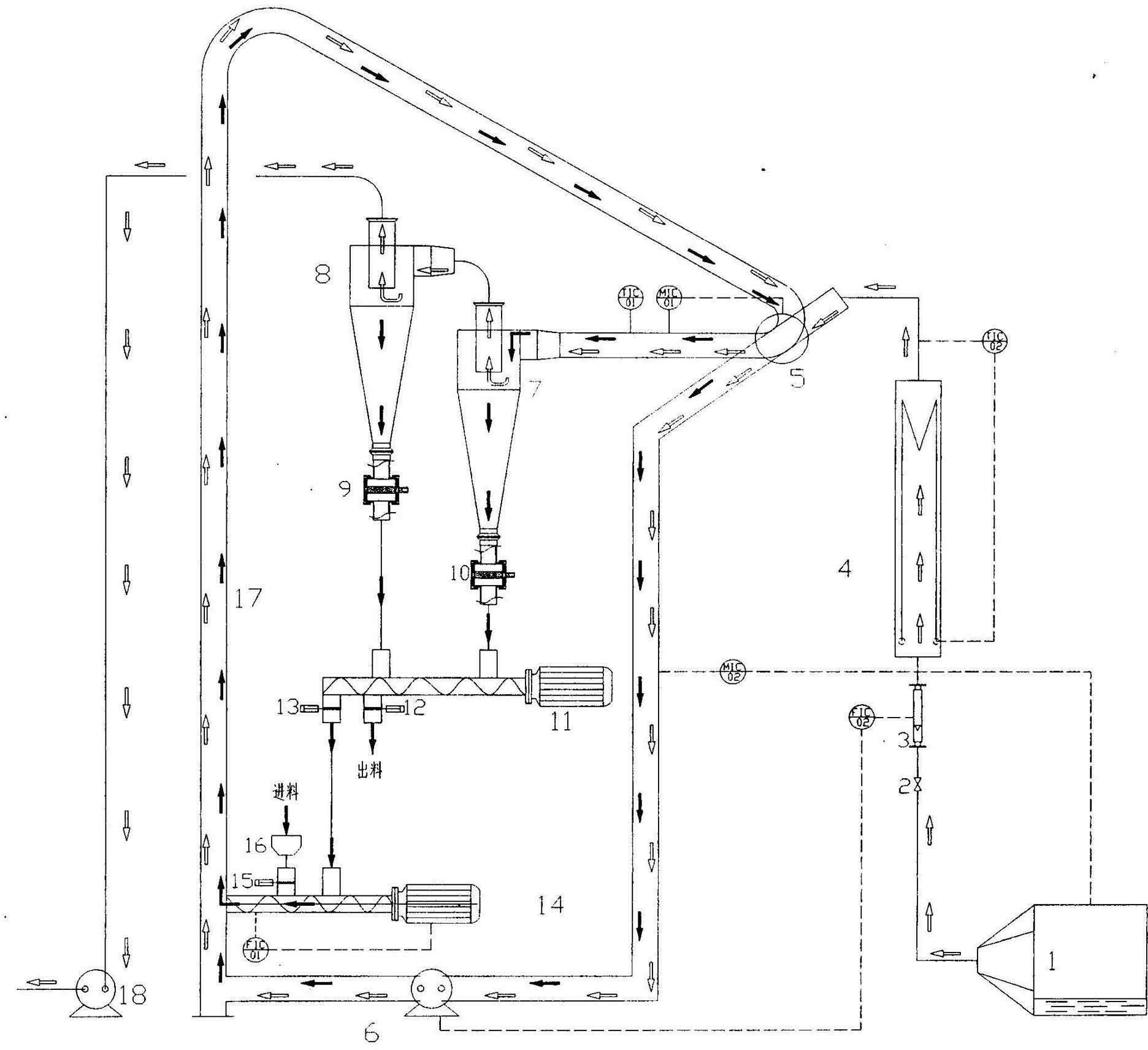

[0021] As shown in the figure: the pilot test recirculating airflow drying device of the present invention comprises a blower 6, a circulating airflow drying pipeline 17, a screw feeder 14, a primary cyclone separator 7, a secondary cyclone separator 8, and an induced draft fan 18 As well as the material conveying system composed of the product screw conveyor 11, an x-shaped valve plate (see figure 2 ) controlled dry material distributor 5, an air inlet of the dry material distributor is connected with a heater 4 and an induced draft box 1 in turn; the outlets of the primary and secondary cyclone separators are respectively provided with an air locker 9 , 10 and link to each other with the product screw conveyor 11, the product screw conveyor is provided with a discharge passage and a mixing passage communicated with the screw feeder and is controlled by the discharge gate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com