Environment-friendly low-radiation concrete production system and production process

A production system and low-radiation technology, applied in the direction of mixing operation control, clay preparation device, mixing operation control device, etc., can solve the problems that raw materials are not easy to fully mix and evenly affect the quality of fresh concrete, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

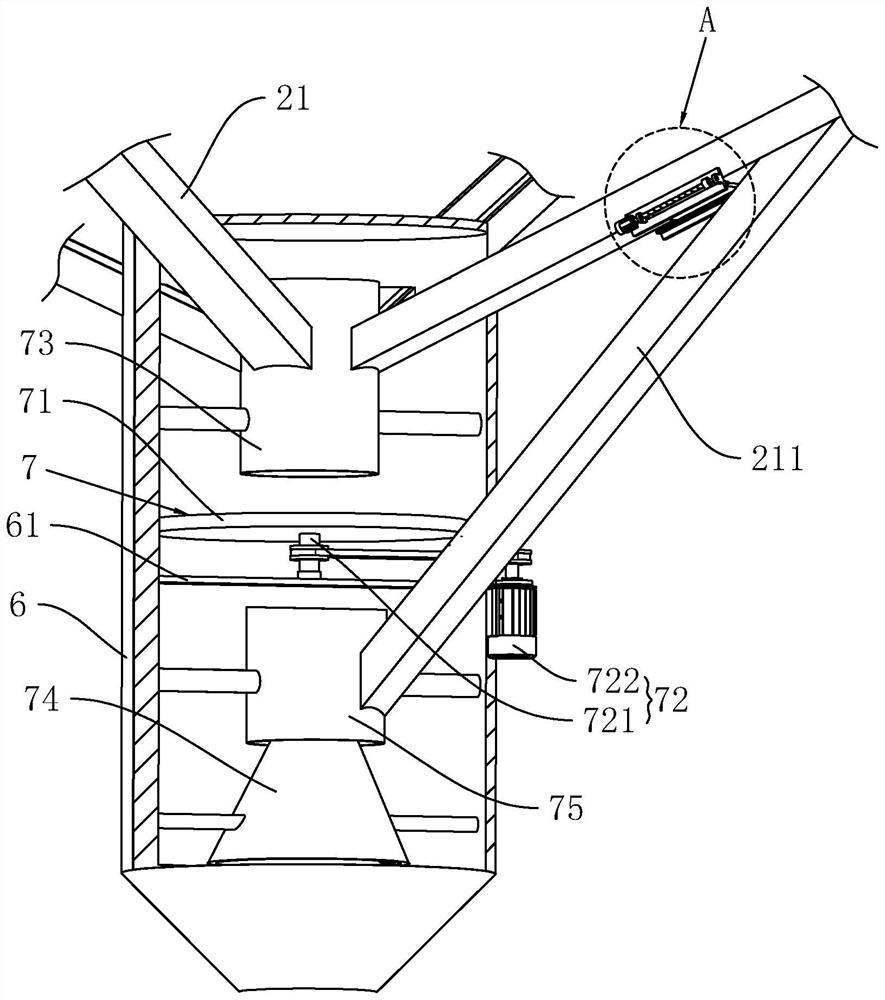

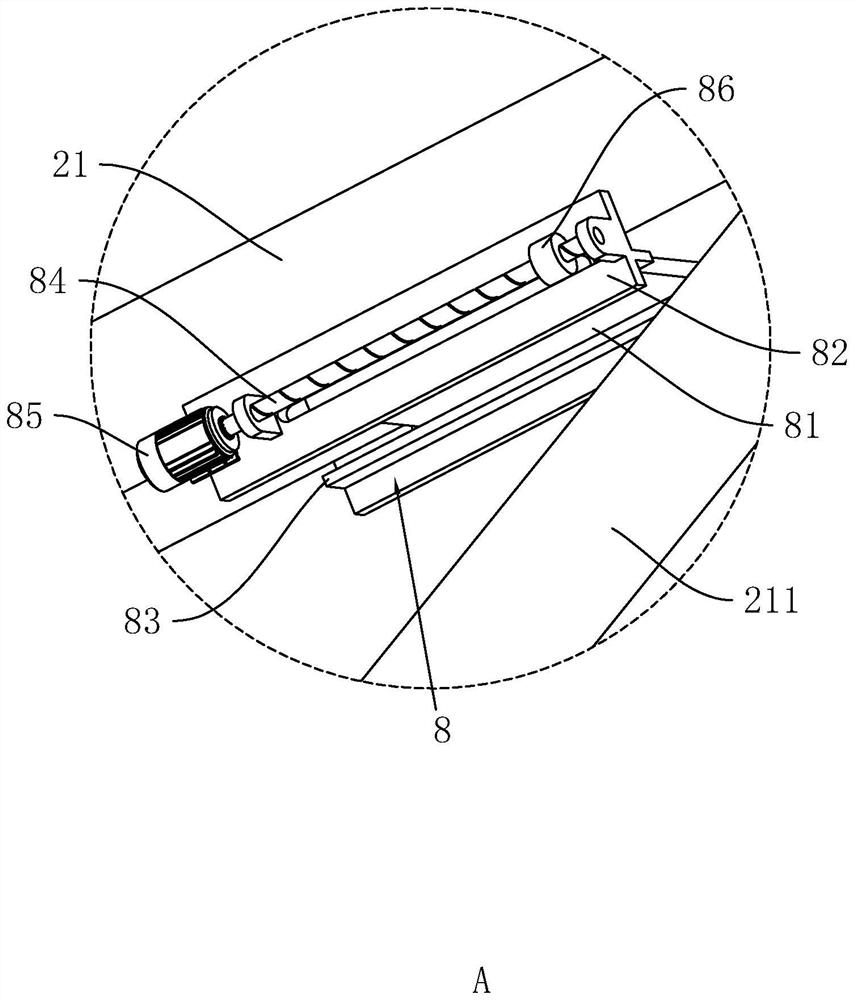

[0033] The application will be described in further detail below in conjunction with all the accompanying drawings.

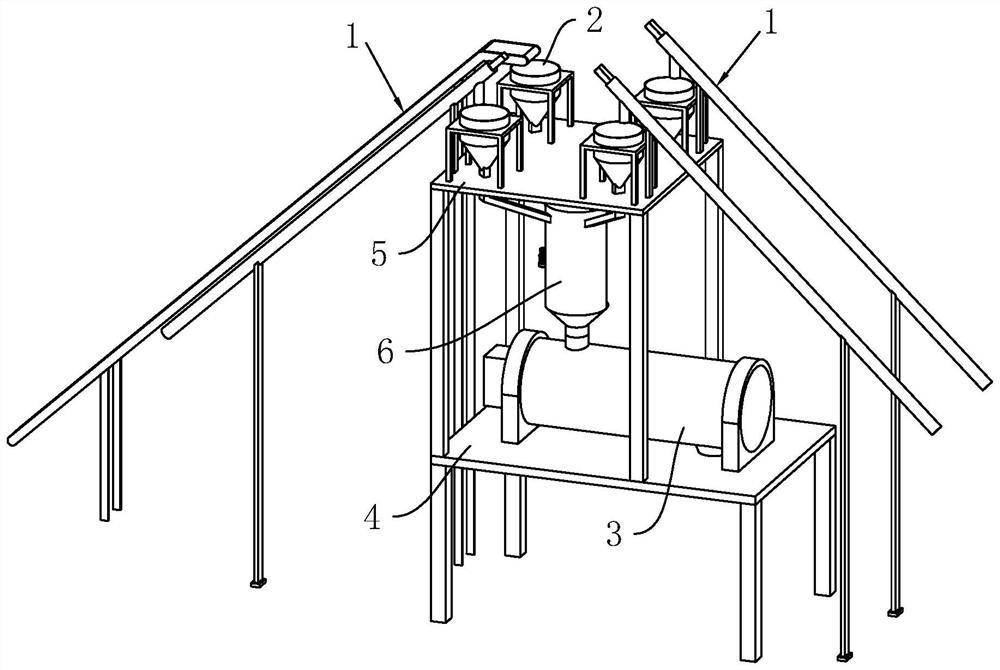

[0034] refer to figure 1 The embodiment of the present application discloses an environmentally friendly low-radiation concrete production system, including a material conveying device 1, a weighing device 2, and a mixer 3. The material conveying device 1 includes a plurality of powder conveying devices and at least one aggregate conveying device, and the weighing The device 2 is provided with a plurality of weighing devices 2, which are respectively used to weigh the materials conveyed by a plurality of powder conveying devices and at least one aggregate conveying device; in this embodiment, the powder conveying device is a screw conveyor, The quantity is set to 3, and the aggregate conveying device is a conveyor belt, the quantity is 1, and the weighing device 2 is a concrete weighing scale, so the quantity is 4; the mixer 3 adopts a horizontal mixer 3.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com