Refining agent and refining method of coal polymer grade glycol

A polymer grade, ethylene glycol technology, which is applied in the field of polymer grade coal-to-ethylene glycol products, can solve the problems of little effect, tedious and complicated, and the decrease of UV value of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

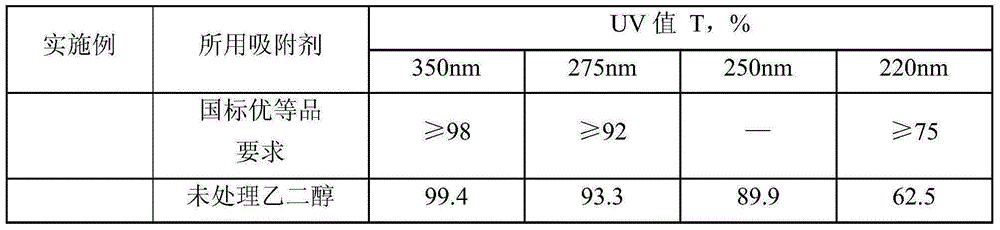

[0031] A variety of commercially available conventional adsorbents were screened for static adsorption treatment of industrial grade coal-to-ethylene glycol. The adsorbent is directly ground into powder without any pretreatment. Static adsorption solid-to-liquid ratio = 1:200, stirring and reacting at 30°C for 4 hours, then use a sand core funnel to filter and measure the UV value of the filtrate, the results are shown in Table 1

[0032] Table 1

[0033]

[0034]

[0035] The results of static adsorption experiments on industrial-grade coal-to-ethylene glycol with nine kinds of adsorbents without any pretreatment in Table 1 show that activated carbon can improve the UV value of raw materials, but the improvement is very limited and cannot reach the polymerization level index. Other adsorbents, such as silica gel, molecular sieve, clay, etc., not only cannot improve the UV value of the raw material, but will reduce it.

Embodiment 10~15

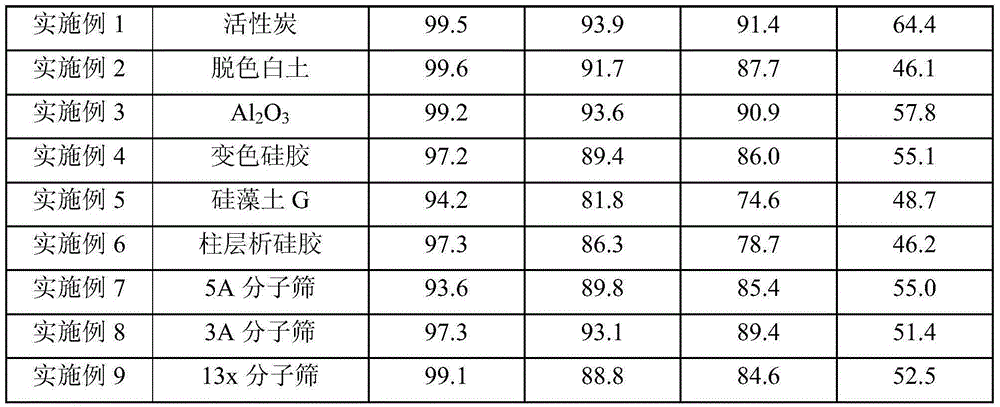

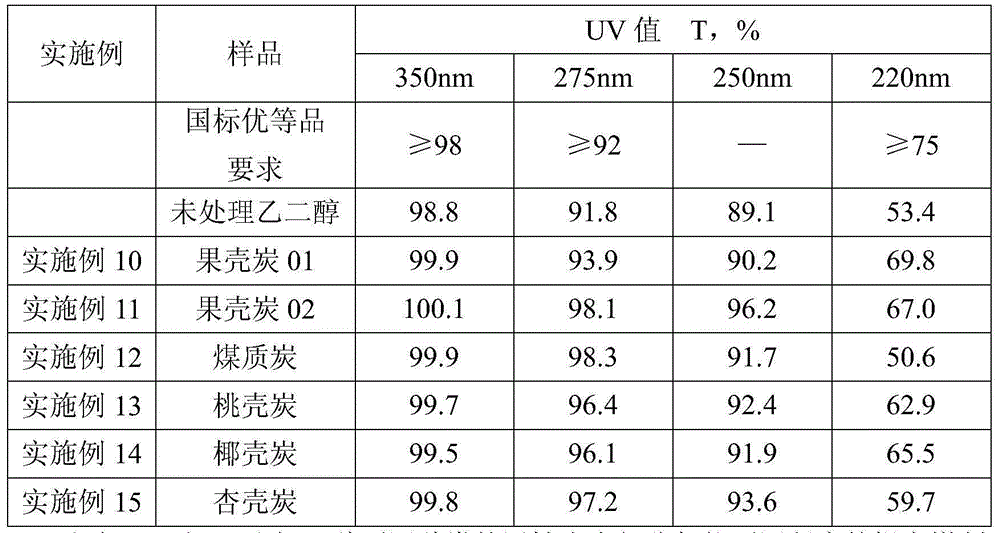

[0037] Collect activated carbon from different manufacturers to perform fixed-bed dynamic adsorption treatment on industrial grade coal-to-ethylene glycol, LHSV=4h -1 , The adsorption temperature is 20-40°C. Activated carbon has not been pretreated, and the UV values of each band of ethylene glycol after treatment are shown in Table 2:

[0038] Table 2

[0039]

[0040] It can be seen from Table 2 that most of the above 6 different types of activated carbon can improve the UV value of coal-to-ethylene glycol to varying degrees, but the improvement is limited and still cannot meet the requirements of polymerization grade, so it is difficult for unmodified activated carbon to meet the requirements. Coal-to-ethylene glycol refining is required to obtain polymer-grade standard ethylene glycol.

Embodiment 16~20

[0042] Select the shell carbon 01 used in Example 10 in the above table, grind it to 20-40 mesh, and pretreat it with different solvents after sieving. Then, 12ml of activated carbon pretreated by different solvents were filled in the quartz tubes of φ10×800mm respectively, and the industrial-grade coal-to-ethylene glycol was subjected to fixed-bed adsorption treatment. Wherein the acid solution used for pretreatment in Example 17 is 15% hydrochloric acid aqueous solution, and the mixed solvent used in Example 20 is the mixed solution of hydrochloric acid, methyl alcohol, water, and wherein, the mass percentage concentration of methyl alcohol and hydrochloric acid is respectively 35% and 15% . The pretreatment method is as follows: soak the activated carbon in the pretreatment solution (the volume of the solution is 2 to 3 times the volume of the activated carbon), stir and impregnate at 50°C for 2 hours, wash it with deionized water, and dry it in an oven at 140°C. LHSV=4h d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com