Preparation method of monodisperse rosinyl polymer microsphere

A polymer microsphere and rosin-based technology, which is applied in the field of preparation of monodisperse rosin-based polymer microspheres, can solve the problems of long cycle, cumbersome preparation steps, and difficult control, and achieve easy operation, simple process, and uniform particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

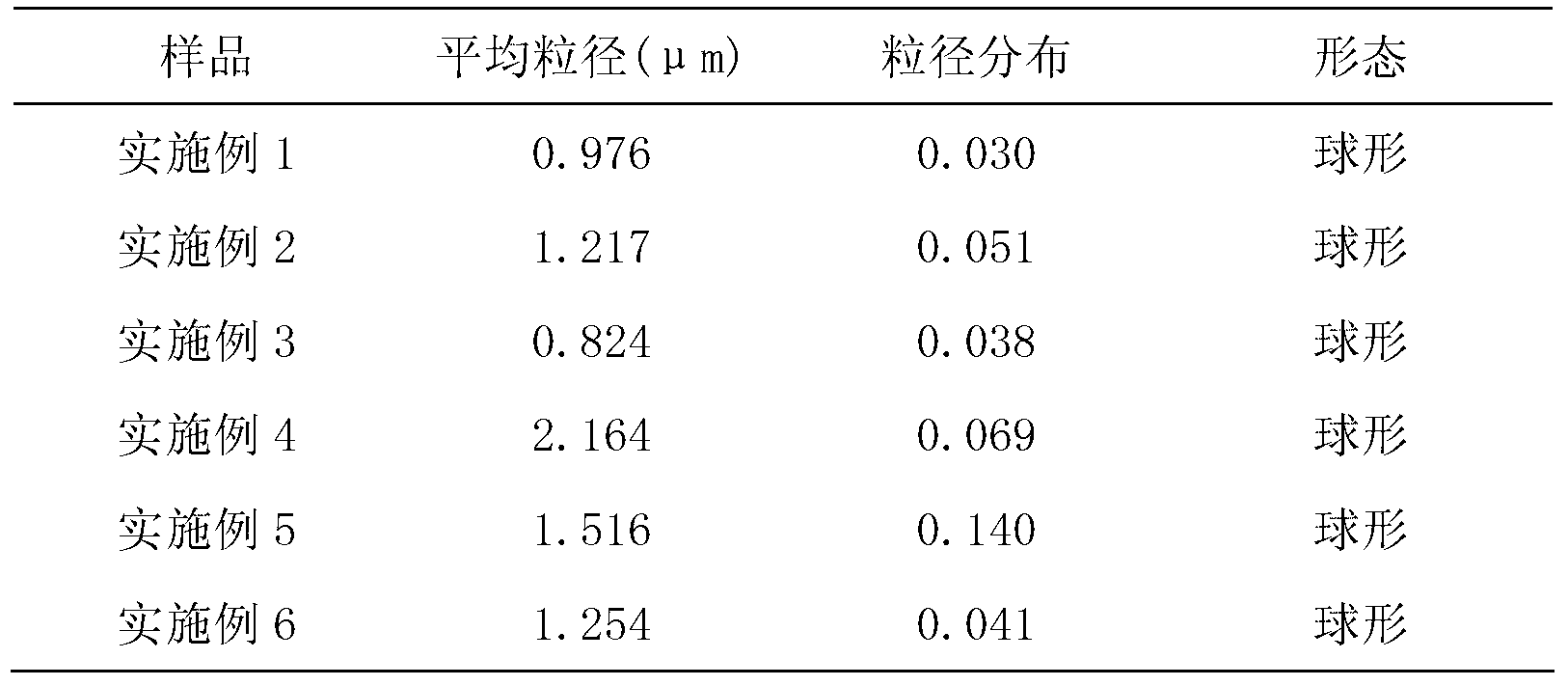

Examples

Embodiment 1

[0016] Add 0.5 g dehydroabietic acid (2-acryloyloxyethyl) ester, 25 mL isopropanol / water (20:5), 0.2 g polyvinylpyrrolidone, 0.001 g azobisiso Butyronitrile, stir to dissolve and mix evenly, and then pass nitrogen gas for 20 minutes to remove oxygen. Stir mechanically at 60°C, and react to obtain a milky white suspension. Settling by centrifugation in an ultracentrifuge, pouring out the supernatant, ultrasonic cleaning, repeated operations four times, drying the cleaned microspheres to constant weight, and obtaining white powdery monodisperse rosin-based polymer microspheres.

Embodiment 2

[0018] Add 0.8 g dehydroabietic acid (2-acryloyloxyethyl) ester, 25 mL isopropanol / water (20:5), 0.2 g polyvinylpyrrolidone, 0.003 g azobisiso Butyronitrile, stir to dissolve and mix evenly, and then pass nitrogen gas for 20 minutes to remove oxygen. Stir mechanically at 60°C. After about 1.5 hours of reaction, the system begins to appear white turbidity, and finally turns into a milky white suspension. Settling by centrifugation in an ultracentrifuge, pouring out the supernatant, ultrasonic cleaning, repeated operations four times, drying the cleaned microspheres to constant weight, and obtaining white powdery monodisperse rosin-based polymer microspheres.

Embodiment 3

[0020] Add 0.5 g of dehydroabietic acid (2-acryloyloxyethyl) ester, 25 mL of isopropanol / water (20:5), 0.2 g of polyvinylpyrrolidone, 0.003 g of azobisiso Butyronitrile, stir to dissolve and mix evenly, and then pass nitrogen gas for 20 minutes to remove oxygen. Stir mechanically at 50°C, the reaction proceeds for about 1.5h, and the system begins to appear white turbidity, and finally turns into a milky white suspension. Settling by centrifugation in an ultracentrifuge, pouring out the supernatant, ultrasonic cleaning, repeated operations four times, drying the cleaned microspheres to constant weight, and obtaining white powdery monodisperse rosin-based polymer microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com