Acrylate emulsion and preparation method thereof

A technology of acrylate and butyl acrylate, which is applied in the field of acrylic emulsion and its preparation, can solve problems such as low adhesion, insufficient hardness of acrylate emulsion, and poor water resistance, and achieve mild preparation conditions, improved water resistance, and easy availability of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

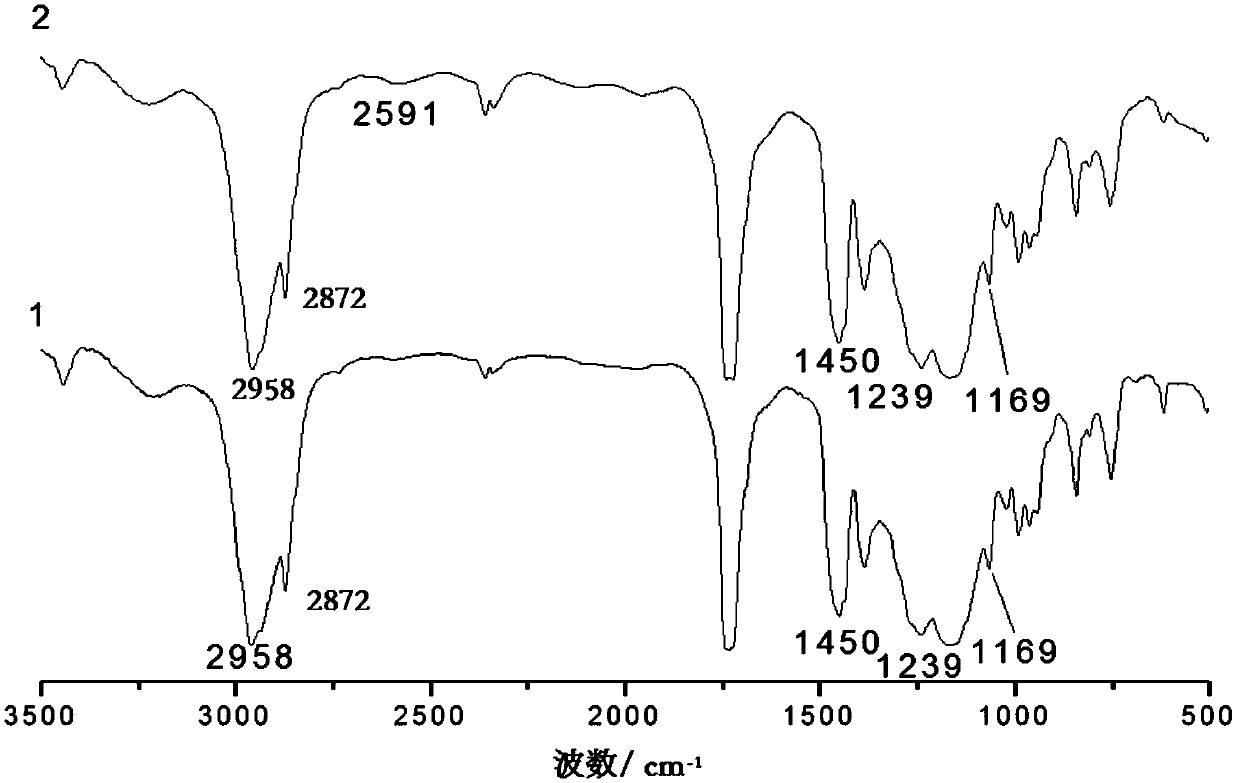

Image

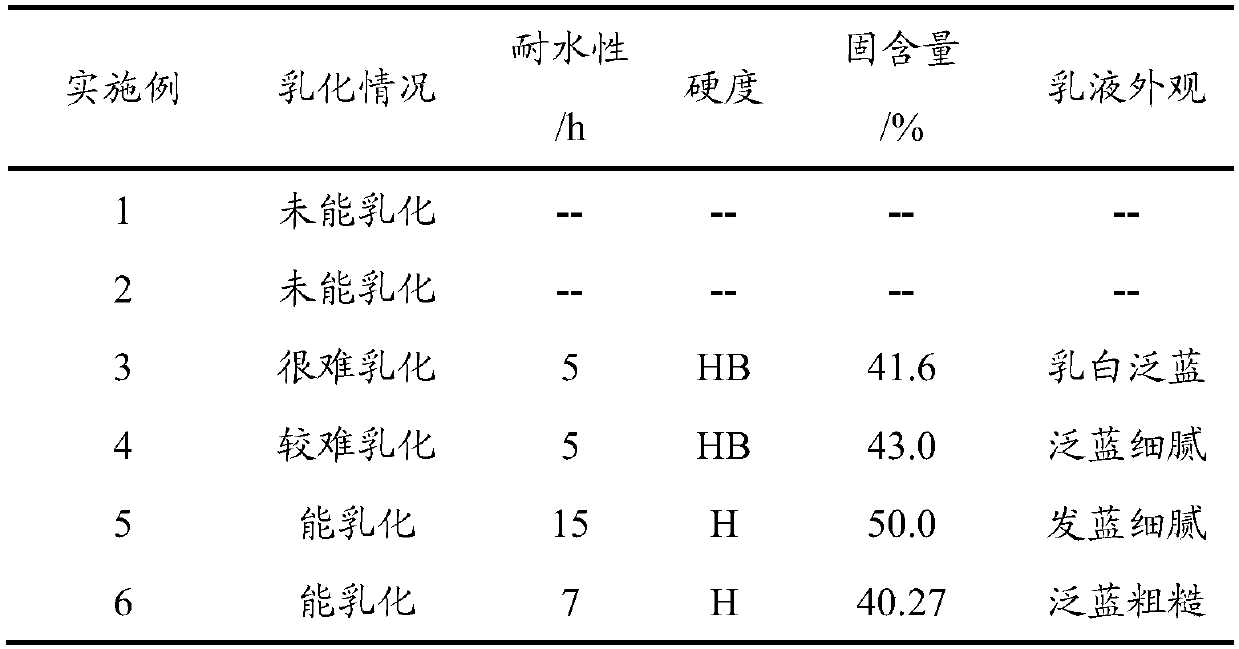

Examples

preparation example Construction

[0062] Another aspect of the present invention is to provide a kind of preparation method of acrylate emulsion, preferably the method for preparing above-mentioned acrylate emulsion, the method comprises the following steps:

[0063] Step 1, prepare pre-emulsion;

[0064] According to the present invention, the concrete process of preparing pre-emulsion is:

[0065] Add emulsifiers SE-10 and OP-10 to 90ml deionized water at the same time, mix well, and prepare a composite emulsifier aqueous solution, and then divide the composite emulsifier aqueous solution into 3 parts by volume, which are 35ml, 25ml and 30ml;

[0066] Add the core monomer into 35ml emulsifier solution, stir and mix thoroughly at room temperature, pre-emulsify for 1.5-2.5 hours, preferably 2 hours, to obtain a pre-emulsified core emulsion; add the shell monomer into 25ml emulsifier aqueous solution, Mix well, and pre-emulsify for 1.5-2.5 hours, preferably 2 hours, to obtain a pre-emulsified shell emulsion; a...

Embodiment 1

[0096] (1) Preparation of pre-emulsion

[0097] Add 0.67g SE-10 and 0.34g OP-10 into 90mL deionized water together to make the emulsifier aqueous solution required for the experiment. The experiment needs to divide the emulsifier aqueous solution into three parts, 35mL, 25mL and 30mL respectively.

[0098] Add the nuclear monomer (35gMMA+15gBA) into 35mL of emulsifier aqueous solution, mix thoroughly under the stirring of an electric stirrer at room temperature, and pre-emulsify for 2 hours to obtain a milky white and stable pre-emulsified nuclear emulsion; similarly , the shell monomer (15gMMA+35gBA) was added to 25mL emulsifier aqueous solution, fully stirred at room temperature, and pre-emulsified for 2h to obtain a pre-emulsified shell emulsion. The remaining 30mL emulsifier aqueous solution was added with 0.3g NaHCO3 buffer to prepare the buffer solution used in the experiment.

[0099] 0.5 g of the initiator was dissolved in 30 ml of deionized water to obtain an aqueou...

Embodiment 2

[0106] The difference between this embodiment and Example 1 is that the composition of the emulsifier is 1.0g SE-10 and 0.5g OP-10, and other steps are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com