Method for preparing lithium cobaltoxide anode thin film of lithium ion battery

A battery lithium cobalt oxide and cathode thin film technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of high energy consumption and high production costs, and achieve the effects of uniform particle size distribution, less waste, and great practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

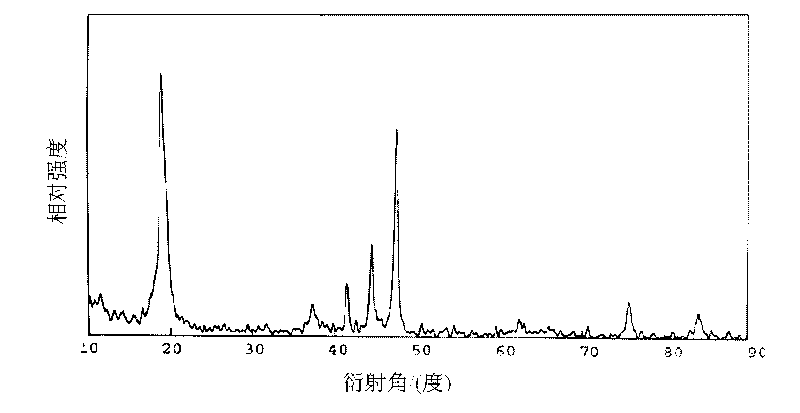

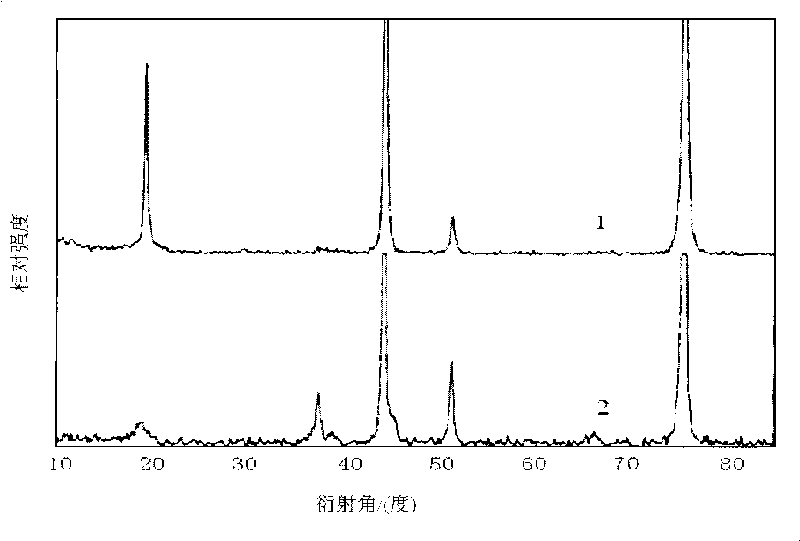

Image

Examples

Embodiment 1

[0034] (1) Mechanical polishing is carried out after the metal Co sheet is drawn, after ultrasonic cleaning in acetone, then ultrasonic cleaning and drying with double distilled water;

[0035] (2) Dissolving 1 to 5 parts of lithium hydroxide in 100 to 500 parts of water to form a homogeneous aqueous solution system;

[0036] (3) Put 100-200ml LiOH solution into the reaction kettle with a polytetrafluoroethylene beaker, control the reaction temperature between 80-200°C, and control the current density at 0.0001-5mA / cm 2 , the reaction time is 1 to 24 hours;

[0037] (4) The working electrode is Co, the counter electrode is metal platinum sheet, and the reference electrode is Ag / AgCl electrode;

[0038] (5) Wash the working electrode with ethanol and deionized water respectively after the reaction;

[0039] (6) Washing and drying to obtain LiCoO with Co matrix 2 thin film electrodes.

Embodiment 2

[0041] (1) Mechanical polishing is carried out after the metal Ni sheet is obtained, after ultrasonic cleaning in acetone, then ultrasonic cleaning and drying with twice distilled water;

[0042] (2) Dissolving 1 to 5 parts of lithium hydroxide in 100 to 500 parts of water to form a homogeneous system of A solution;

[0043] (3) Dissolving 1 to 5 parts of cobalt nitrate in 10 to 50 parts of water to form a homogeneous system of B solution;

[0044] (4) Mix 1-10 parts of B solution with 1-10 parts of A solution to obtain Co(OH) 2 precipitation;

[0045] (5) Mix Co(OH) under stirring condition 2 Add 100-200ml LiOH solution to form a turbid solution;

[0046](6) Put the turbid liquid into a reaction kettle with a polytetrafluoroethylene beaker, control the reaction temperature between 80 and 200°C, and control the current density at 0.0001 to 5mA / cm 2 , the reaction time is 1 to 24 hours;

[0047] (7) The working electrode is a nickel sheet, the counter electrode is a metal ...

Embodiment 3

[0051] (1) Mechanical polishing is carried out after the metal Ni sheet is obtained, after ultrasonic cleaning in acetone, then ultrasonic cleaning and drying with twice distilled water;

[0052] (2) Dissolving 1 to 5 parts of lithium hydroxide in 100 to 500 parts of water to form a homogeneous system of A solution;

[0053] (3) Dissolving 1 to 5 parts of cobalt chloride in 10 to 50 parts of aqueous solution to form a homogeneous system of B solution;

[0054] (4) Mix 1-10 parts of B solution with 1-10 parts of A solution to obtain Co(OH) 2 precipitation;

[0055] (5) Mix Co(OH) under stirring condition 2 Add 100-200ml LiOH solution to form a turbid solution;

[0056] (6) Put the turbid liquid into a reaction kettle with a polytetrafluoroethylene beaker, control the reaction temperature between 80 and 200°C, and control the current density at 0.0001 to 5mA / cm 2 , the reaction time is 1 to 24 hours;

[0057] (7) The working electrode is a nickel sheet, the counter electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com