MU five-point zero ceramsite composite self-insulation building block

A self-insulation block and composite insulation technology, which is applied in the field of insulation blocks, can solve problems such as unsatisfactory and meeting demands, and achieve the effects of improving construction efficiency, assembly strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

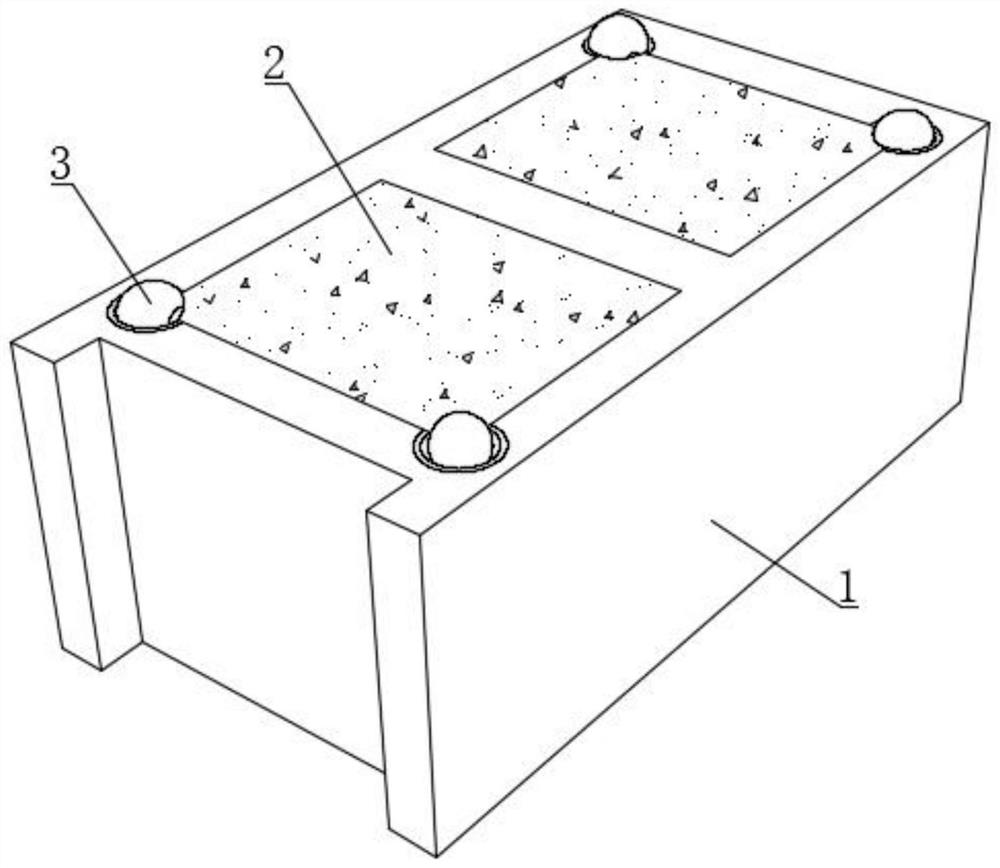

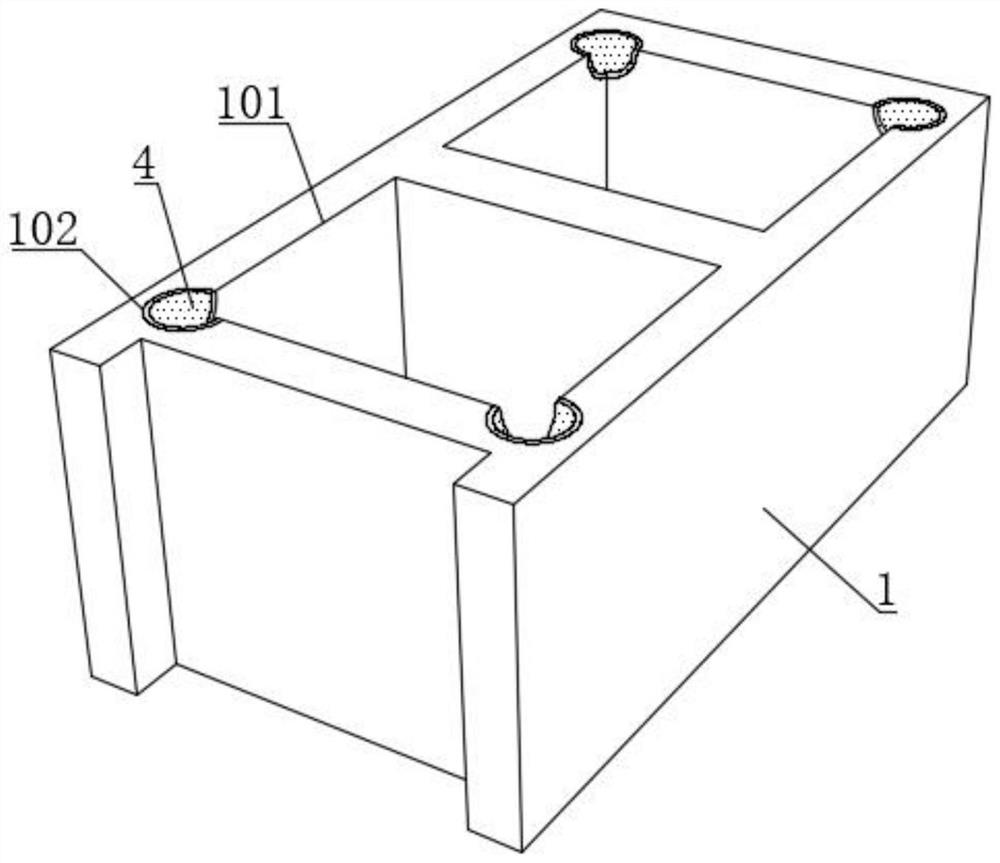

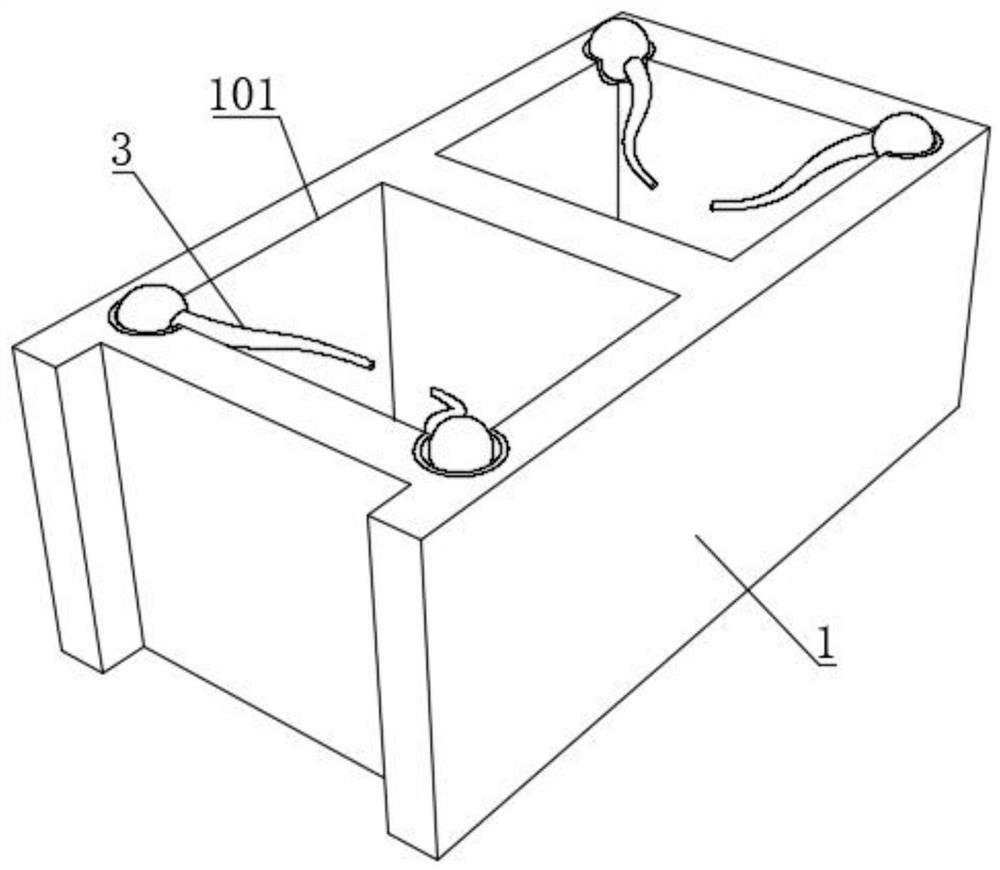

[0042] see figure 1 and figure 2 , a MU five point zero ceramsite composite self-insulating block, including a composite insulating hollow block 1, a pair of casting cavities 101 are opened on the composite insulating hollow block 1, and the inside of the casting cavity 101 is filled with ultra-light foamed concrete 2 , the upper end of the composite thermal insulation hollow block 1 is provided with a plurality of main grooves 102, the plurality of main grooves 102 are evenly distributed on both sides of a pair of casting cavities 101, and the main grooves 102 communicate with the casting cavity 101, please refer to image 3 , the inside of main groove 102 is placed with foaming agent 3, and the tail of foaming agent 3 is positioned at the inboard of casting cavity 101, please refer to Figure 4 , the lower end of the composite thermal insulation hollow block 1 is provided with a plurality of auxiliary grooves 103, the number and size of the auxiliary grooves 103 and the ma...

Embodiment 2

[0054] Compared with Example 1, Example 2 does not set the blowing agent 3 and its related structures.

[0055] A MU five point zero ceramsite composite self-insulating block, including a composite insulating hollow block 1, a pair of casting cavities 101 are opened on the composite insulating hollow block 1, and the inside of the casting cavity 101 is filled with ultra-light foamed concrete 2, The composite thermal insulation hollow block 1 includes the following raw materials: cement, aggregate, admixture and water. The weight ratio of various raw materials is: cement: ceramsite: ceramsite: admixture: water = 1:0.5:0.85:0.55:0.2.

[0056] A kind of MU 5.0 ceramsite composite self-insulation block, its preparation method is:

[0057] Step 1: Those skilled in the art put cement, ceramsite, ceramsite, admixture and water into a mixer according to the weight ratio of the above raw materials and mix them uniformly to obtain a mixed slurry;

[0058] Step 2: Transport the mixed sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com