Ultralow temperature high-performance concrete composite anti-freezing agent and preparation technology thereof

A high-performance concrete and antifreeze technology, applied in the field of concrete admixtures, can solve the problems of low input cost, achieve low input cost, reasonable design, and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The composition of the composite antifreeze agent for ultra-low temperature and high performance concrete prepared by the present invention is: 30% to 35% of nitrate, 30% to 33% of organic compound, 0.5% to 1% of calcium formate, and the balance is water; the nitric acid The salt is calcium nitrate or calcium nitrite, and the organic compound is methanol or ethanol.

[0026] In the present embodiment, the nitrate used in the composite antifreeze is calcium nitrate, and the composition of the composite antifreeze is by weight: 30% nitrate, 33% organic compound, 0.75% calcium formate, and the balance is water. The nitrate is calcium nitrate, and the organic compound is methanol or ethanol.

[0027] When actually preparing the composite antifreeze, the dosages of the nitrate, organic compound, calcium formate and water can be adjusted accordingly according to specific needs.

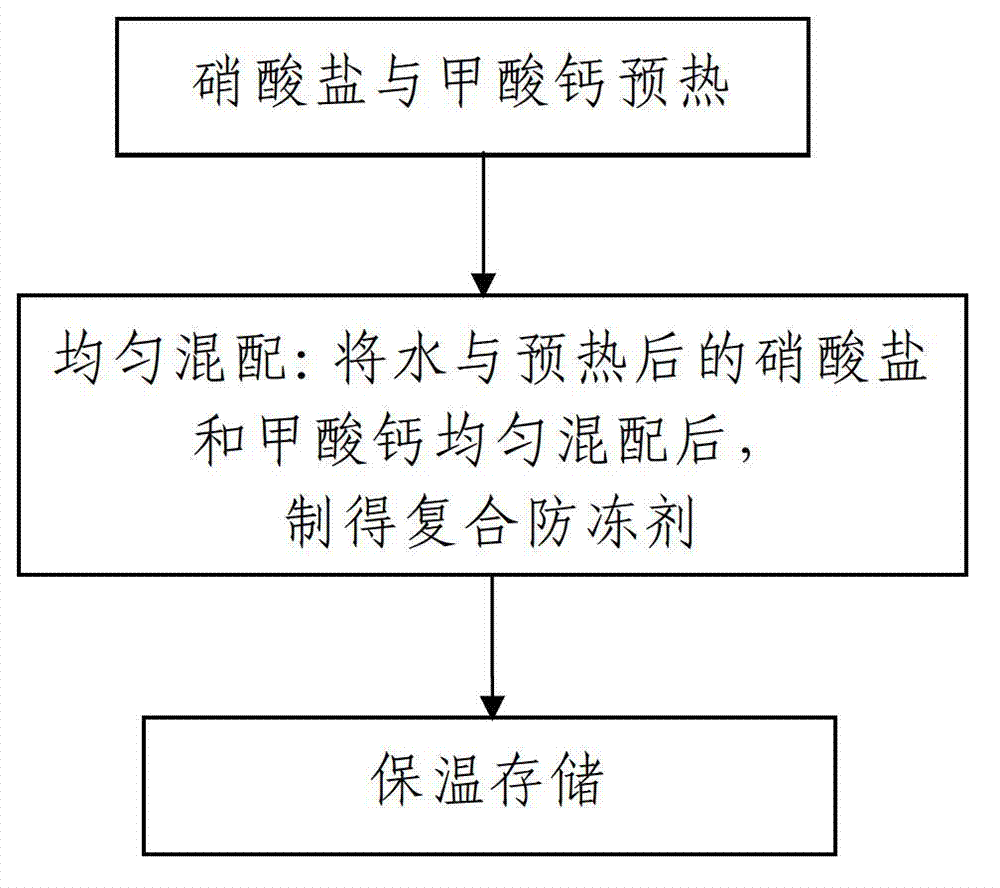

[0028] Such as figure 1 The preparation process of the shown ultra-low temperature high-perfor...

Embodiment 2

[0106] In the present embodiment, the prepared ultra-low temperature high-performance concrete composite antifreeze is different from Example 1 in that: the composition of the composite antifreeze is by weight: 35% of nitrate, 30% of organic compound, 0.5% of calcium formate, and the remaining The amount is water.

[0107] In this example, the preparation process of the ultra-low temperature high-performance concrete composite antifreeze agent used is the same as that in Example 1.

Embodiment 3

[0109] In the present embodiment, the prepared ultra-low temperature high-performance concrete composite antifreeze is different from Example 1 in that: the composition of the composite antifreeze is by weight: 32% of nitrate, 31% of organic compound, 0.8% of calcium formate, and the remaining The amount is water.

[0110] In this example, the preparation process of the ultra-low temperature high-performance concrete composite antifreeze agent used is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com