Construction technique for ultralow-temperature high-property concrete for railway construction in frigid areas

A technology of high-performance concrete and construction technology, which is applied in the processing of building materials, construction, building construction, etc., to achieve the effects of increasing mixing temperature and mold entry temperature, simple design process, and convenient optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

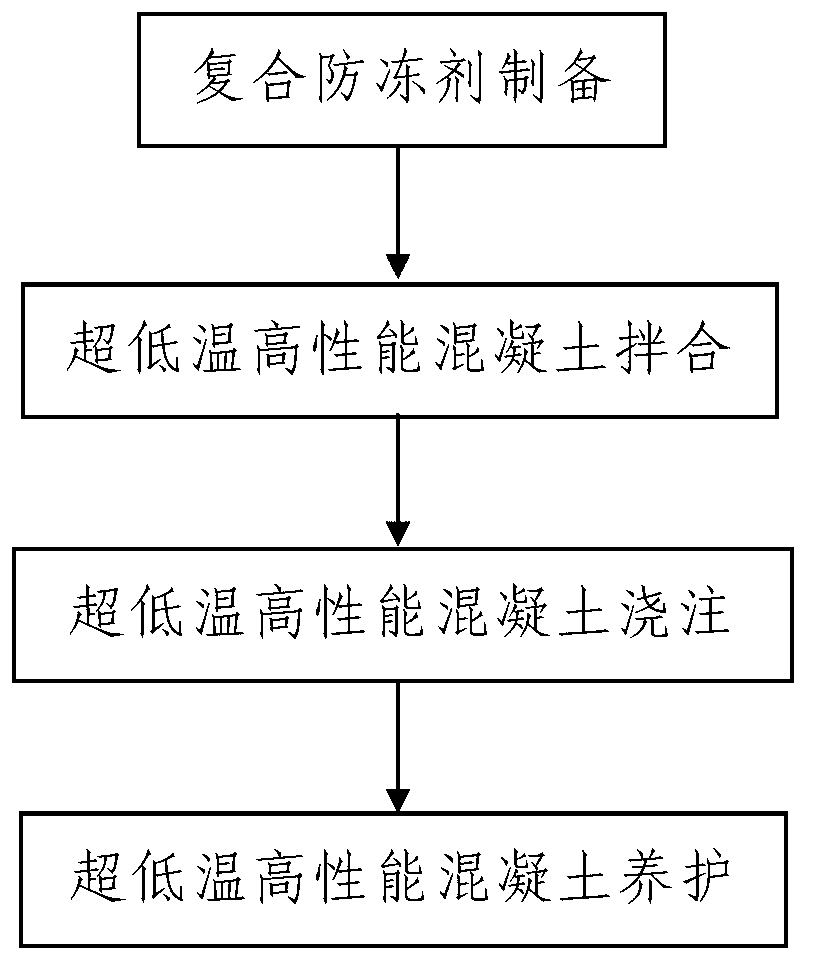

[0039] Such as figure 1 A construction process of ultra-low temperature high-performance concrete for railway construction in severe cold areas shown, including the following steps:

[0040] Step 1. Mixing of ultra-low temperature and high-performance concrete: After uniform mixing of cementitious materials, sand, gravel, high-efficiency water reducer, composite antifreeze and water, the bulk density is 2350kg / m 3 ~2450kg / m 3 ultra-low temperature high-performance concrete. The maximum water-binder ratio and sand ratio of the ultra-low temperature high-performance concrete are all based on the design drawings of the concrete structure to be constructed, and are designed according to the mix ratio design method of concrete for railway construction, which is a conventional railway well-known by those skilled in the art. Mix design method of concrete for construction.

[0041] The cementitious material is uniformly mixed with cement and mineral admixtures in a weight ratio of ...

Embodiment 2

[0136]In this embodiment, the difference between the ultra-low temperature high-performance concrete mixed in step 1 and the embodiment 1 is that the water-binder ratio of the ultra-low temperature high-performance concrete is 0.3, and the weight ratio of sand to cementitious material is 1.4-1.5. The sand rate is 32%, the weight ratio of cement and fly ash in the cementitious material is 88:12, the weight ratio of the composite antifreeze to the cementitious material is 4:100, and the weight ratio of the superplasticizer to the cementitious material is 0.8:100; the composite antifreeze used is different from that of Example 1 in that the composition of the composite antifreeze is by weight: 35% nitrate, 30% organic compound, 0.5% calcium formate, and the balance is water.

[0137] In this embodiment, the proportions of the remaining components of the ultra-low temperature high-performance concrete used, as well as the process steps and process parameters of the construction pro...

Embodiment 3

[0139] In this embodiment, the difference between the ultra-low temperature high-performance concrete mixed in step 1 and the embodiment 1 is that the water-binder ratio of the ultra-low temperature high-performance concrete is 0.4, and the weight ratio of sand to cementitious material is 1.7-1.8. The sand rate is 38%, the weight ratio of cement and fly ash in the cementitious material is 78:22, the weight ratio of the composite antifreeze to the cementitious material is 5:100, and the weight ratio of the superplasticizer to the cementitious material is 1: 100; the composite antifreeze used is different from Example 1 in that the composition of the composite antifreeze is by weight: 32% nitrate, 32% organic compound, 0.8% calcium formate, and the balance is water.

[0140] In this embodiment, the proportions of the remaining components of the ultra-low temperature high-performance concrete used, as well as the process steps and process parameters of the construction process are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com