Manufacturing technology for autoclaving-free pole

A production process and technology without steam curing, which is applied in the direction of manufacturing tools, reinforced molding, ceramic molding machines, etc., can solve the problems of concrete performance impact of electric poles, increase the production links of electric poles, shorten the time of formwork removal, etc., and achieve the change of high energy consumption History, beautiful appearance, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

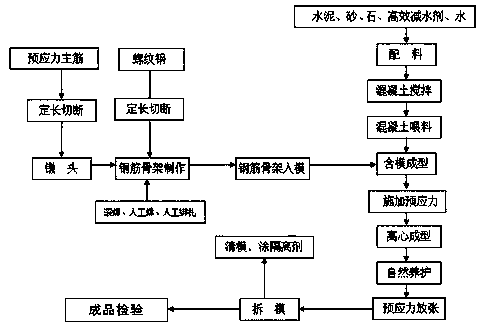

Image

Examples

Embodiment Construction

[0025] Referring to the accompanying drawings, a steam-free curing pole production process, the specific processing steps are as follows: the first step: prestressed steel bars and rebar processing: prestressed steel bars and rebars are cut on a high-precision fixed-length cutting machine, respectively. Upsetting, the strength loss of upsetting is not more than 10%;

[0026] Step 2: Reinforcement skeleton production: the above prestressed rebar is the main rebar, the rebar is the hoop rebar, the main rebar and the hoop rebar are manually bound, and then manually welded. The tensile strength and yield strength of the welding point shall not be lower than 95% of the strength of the main reinforcement and the circumferential reinforcement, and the depth of the welding point shall not be greater than 1mm.

[0027] Step 3: Making the concrete mix:

[0028] Concrete mixture includes cement, sand, stone, superplasticizer, drinking water;

[0029] (1) Preparation of sand and stone: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com