Comprehensive utilization method of cyanamide waste residue

A waste slag and cyanamide technology, applied in the direction of chemical instruments and methods, carbon compounds, carboxylate preparation, etc., can solve the problems of low quality of calcium carbonate or lime and high processing cost, and achieve low processing cost, simple process, and improved The effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

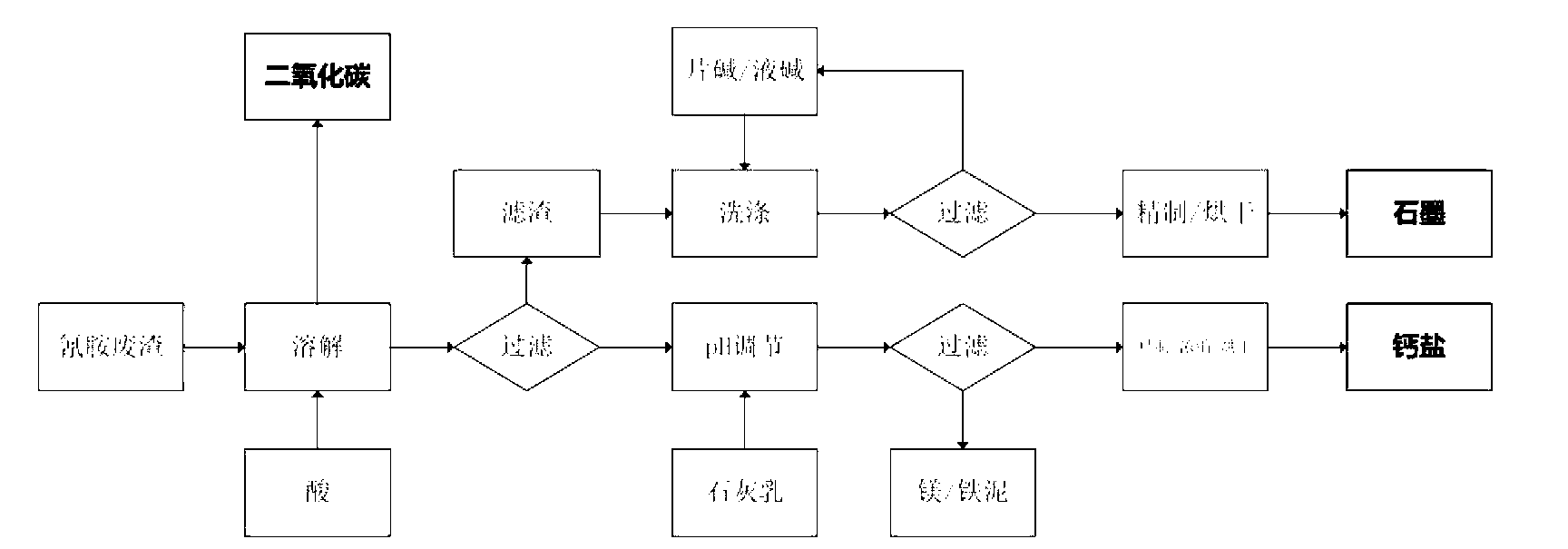

Method used

Image

Examples

Embodiment 1

[0045] Weigh 1000g of waste residue (moisture content 38%) and add it to a 2000ml beaker, slowly add 1300g of 30% hydrochloric acid, stir while adding, slowly release carbon dioxide gas (about 120 liters), after the dropwise addition, measure pH = 1.6. Suction filtration, drying to obtain 90g of black filter residue (95% is carbon element through elemental analysis). Heat the filtrate to 30-70°C, adjust the pH to 8.5 with an appropriate amount of calcium hydroxide, let it stand still, filter, evaporate and concentrate to remove free water, crystallize, and dry (about 180-200°C) to obtain 760g of calcium chloride dihydrate.

Embodiment 2

[0047]Weigh 2002g of waste residue (moisture content 37.5%) and add it to a 5000ml beaker, slowly add 2650g of 30% hydrochloric acid, stir while adding, slowly release carbon dioxide gas (about 230 liters), after the dropwise addition, measure pH = 1.8. Suction filtration, drying to obtain 190g of black filter residue (the main component is carbon). Heat the filtrate to 60-80°C, adjust the pH to 8.8 with an appropriate amount of calcium hydroxide, let it stand still, filter, evaporate and concentrate to remove free water, crystallize, and dry (about 180-200°C) to obtain 1170g of anhydrous calcium chloride.

Embodiment 3

[0049] Weigh 500% of waste residue (moisture content 38.0%) into a 1000ml beaker, slowly add 520g of 65% nitric acid, stir while adding, slowly release carbon dioxide gas (about 60 liters), after the dropwise addition, measure pH = 1.8. Suction filtration, drying to obtain 48g of black filter residue (the main component is carbon). The filtrate is heated to 70-100°C, the filtrate is adjusted to pH = 9.0 with an appropriate amount of calcium hydroxide, and then left to stand, filtered, evaporated and concentrated to remove free water, crystallized, and dried (about 180-200°C) to obtain 630g of calcium nitrate tetrahydrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com