Quick-setting agent and quick-setting polymer cement waterproof slurry and preparation method thereof

A technology of waterproof slurry and quick-setting agent, which is applied in the field of waterproof slurry, and can solve problems such as the impossibility of quick repair projects and rush-duration projects, the slow setting speed of waterproof slurry, and the fast setting speed of waterproof slurry, so as to achieve waterproof effect Good, long construction time, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

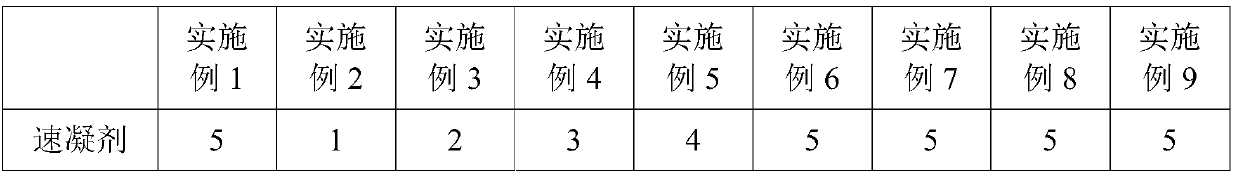

[0070] The preparation method of each embodiment of the present invention comprises the following steps:

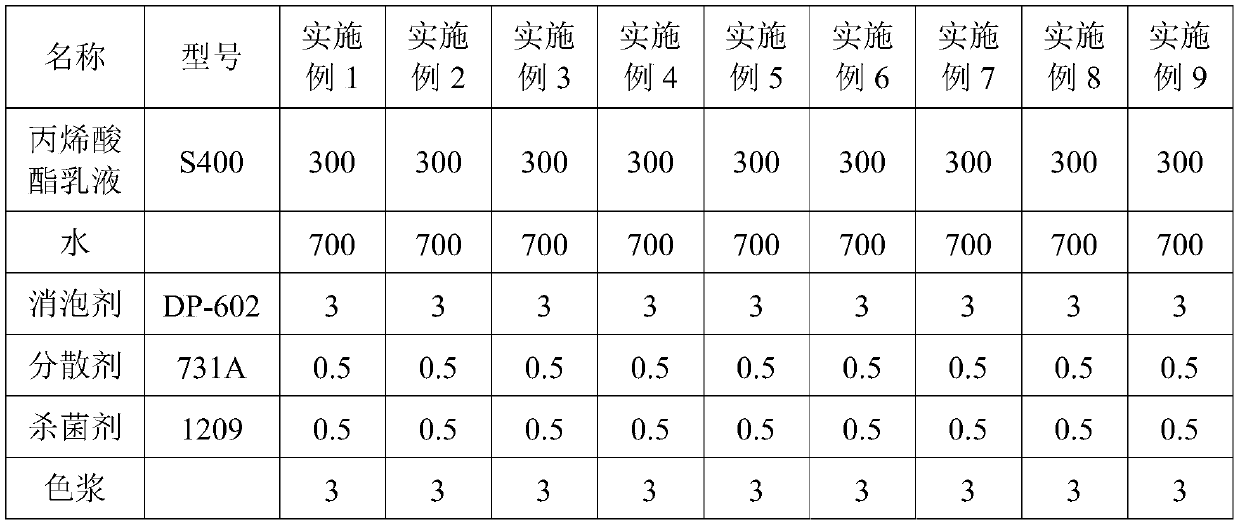

[0071] Liquid material: Measure water into the liquid material mixing tank, turn on the disperser of the mixing tank, keep the speed at 1000 rpm, then add the S400 acrylate emulsion into the liquid material mixing tank to disperse for 10 minutes, then Reduce the stirring speed to 800 rpm, then measure 602 defoamer, 731A dispersant and 1209 bactericide into the liquid material mixing tank, stir for 10 minutes, and finally add color paste for coloring, and stir for 10 minutes to obtain liquid material.

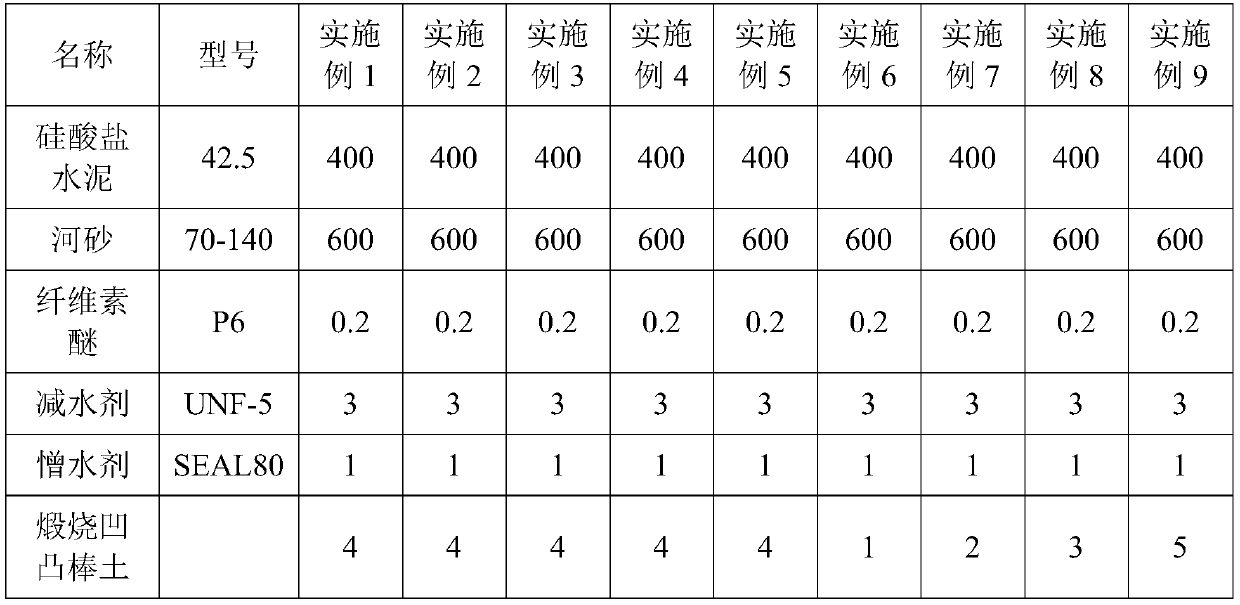

[0072] Powder: Turn on the gravity-free powder mixer, keep the speed at 600 rpm, then add 42.5 Portland cement to the powder mixing tank after measuring, add 70-140 mesh river sand to the mixing tank, and then Add P6 cellulose ether, anti-osmosis additive, UNF-5 water reducer, and SEAL80 water repellent to a gravity-free mixing tank and stir for 10 minutes before packaging...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com