Blending material for high-early-strength concrete

An admixture and concrete technology, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of early strength decline of concrete, reduce cement consumption, improve comprehensive performance, and have broad application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

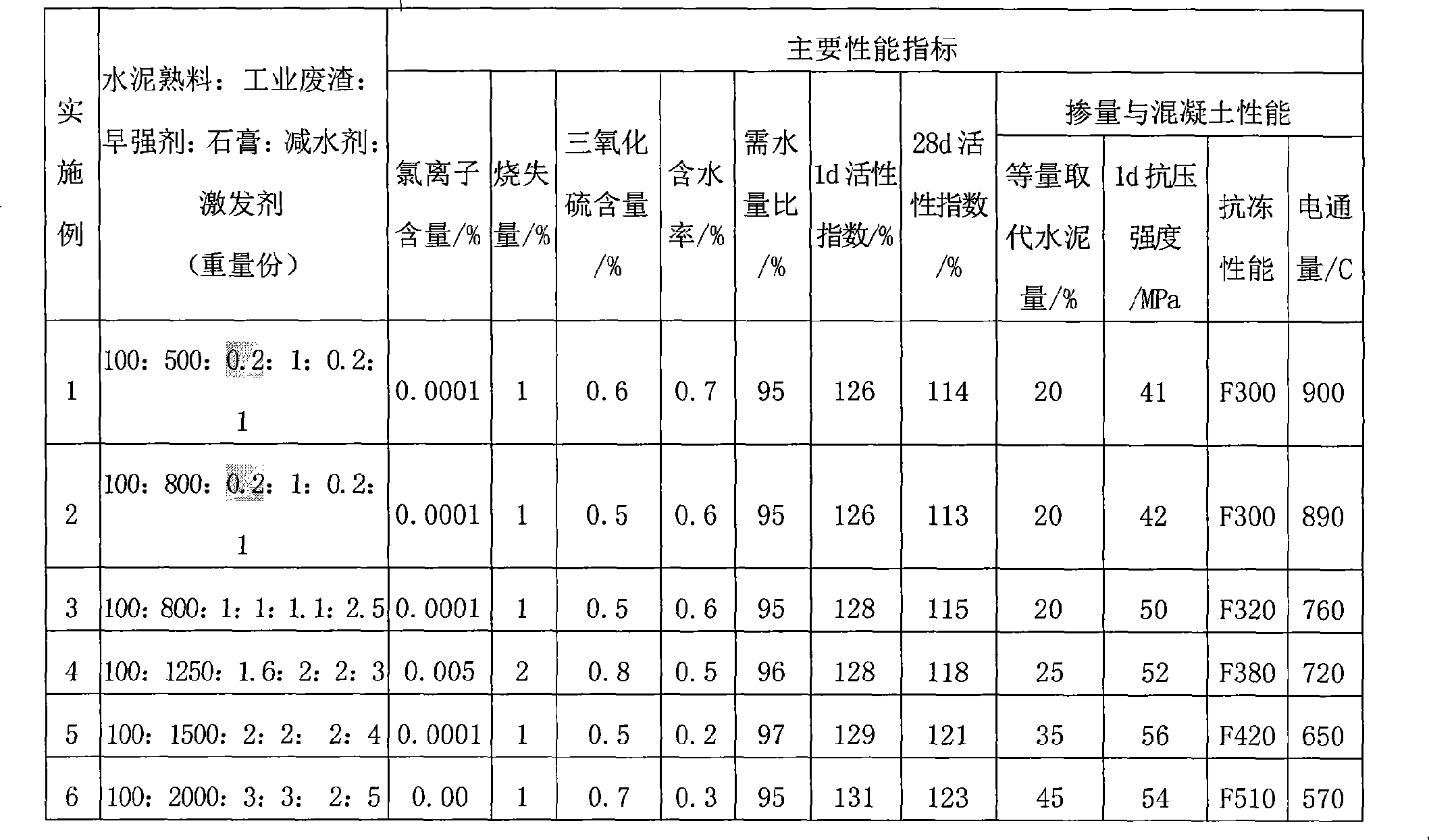

Examples

Embodiment 7

[0018] An admixture for concrete, which is formed by mixing and stirring cement clinker, industrial waste residue, early strength agent, gypsum, water reducing agent and activator, and the parts by weight of each component are: cement clinker: 100 parts, Industrial waste residue: 1400 parts, early strength agent: 2.5 parts, gypsum: 1.5 parts, water reducing agent: 0.8 parts, activator: 3.5 parts. The cement clinker is Portland cement clinker; the industrial waste slag is a 0.2:1:1:1 mixture of microsilica fume, fly ash, ground steel slag powder and ground coal gangue powder; the early strength agent is three 80:20 mixture of ethanolamine and lithium carbonate; 75:25 mixture of aluminum hydroxide and calcium nitrite as activator; water reducer is polycarboxylic acid series water reducer.

[0019] After all the raw materials are weighed according to the proportion, they are added into the mixer together and stirred for 100 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com