Early-strong-fast-hard end capping anchorage mortar material for fragment-free railway plate

A technology of railway track and mortar material, which is applied in the direction of track, road, ballast layer, etc., can solve the problem of not being able to seal the end of the track plate and anchor material, and achieve the effect of excellent mortar performance, stable volume and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

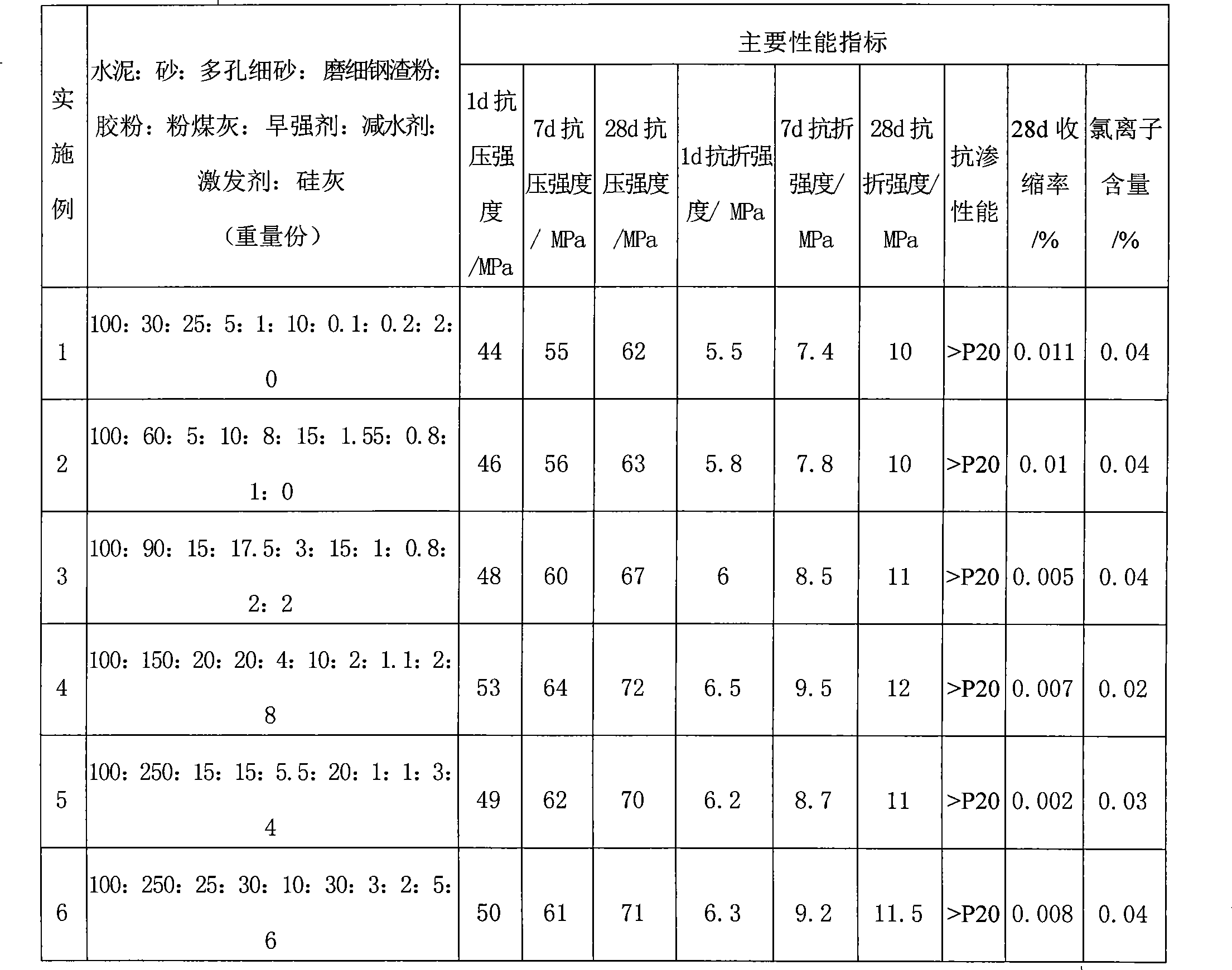

Examples

Embodiment 7

[0023] An early-strength and quick-hardening anchoring mortar material for ballastless railway track slabs, which is mainly composed of cement, sand, porous fine sand, finely ground steel slag powder, fly ash, early-strength agent, rubber powder, silica fume, water-reducing It is made by mixing and stirring raw materials of activator and activator. The parts by weight of each raw material are: cement: 100 parts, sand: 150 parts, porous fine sand: 15 parts, finely ground steel slag powder: 25 parts, fly ash: 30 parts, Early strength agent: 1 part, rubber powder: 4 parts, silica fume: 5 parts, water reducing agent: 1 part, activator: 1 part, the ground steel slag powder is ground and stored naturally within 3-6 months converter steel slag with a specific surface area of 500m 2 / kg, and the magnesium oxide content is 12%; the porous fine sand is a 1:1 mixture of shale pottery sand and fly ash pottery sand, with a particle size of 0.10-2.6mm; rubber powder is from vinyl acetate-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com