External insulation construction method for fiber polymer cement mortar composite polyphenylene plate

A technology of fiber polymer and cement mortar, applied in thermal insulation and building components, etc., can solve the problems of low construction efficiency, difficulty in fully guaranteeing quality, complicated construction procedures, etc., achieve convenient construction, solve waterproof problems, and avoid shrinkage cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

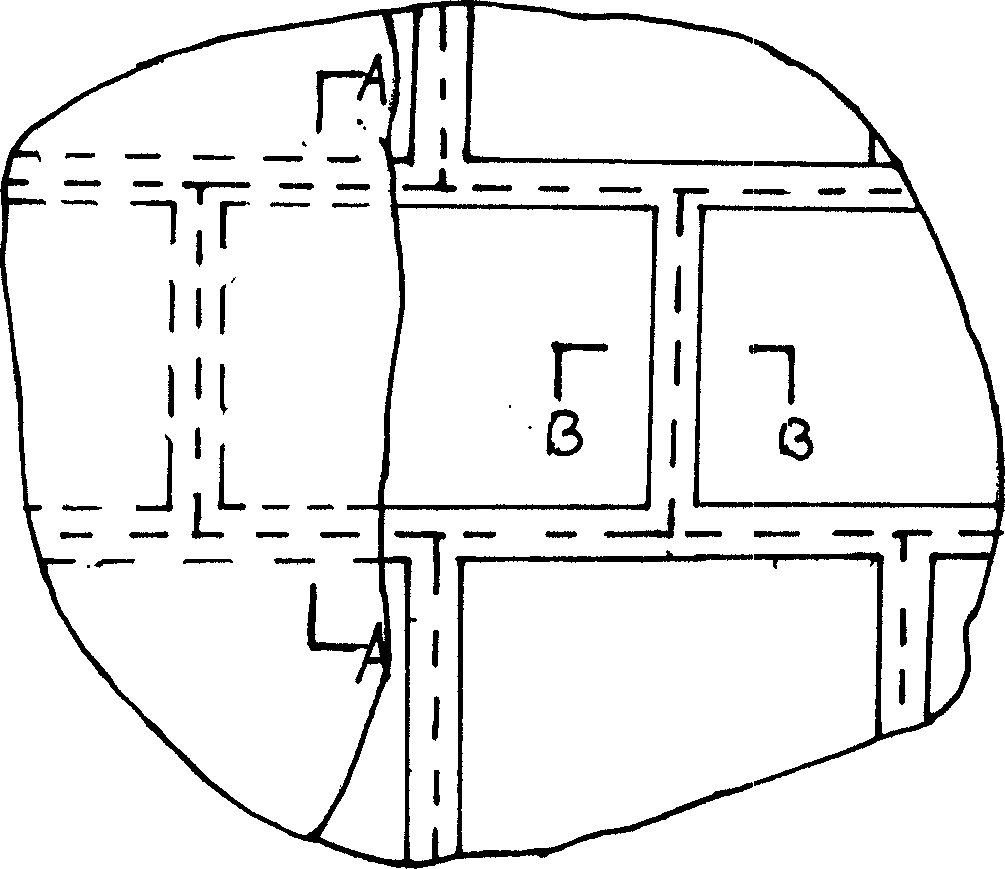

[0023] 1. The polystyrene board and the treated wall are connected by polymer cement mortar, and the joint structure of the polystyrene board adopts the form of staggered joints;

[0024] 2. After the polystyrene board is pasted on the entire wall, a slotting method is used to cut the upper and lower edges of the windows on each layer, and a divisional seam is set at a depth of 2 cm, and then the divisions are treated with waterproof caulking ointment or sealing strips. grid;

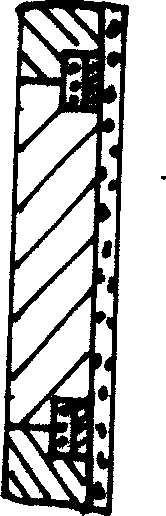

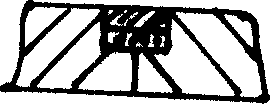

[0025] 3. At the lap joint, the polystyrene board has a downward concave platform within a width of 1 cm from the edge of the board, and its depth is 2 mm. Coat the edges of every two polystyrene boards with fiber polymer cement mortar In the groove of the joint, paste alkali-resistant glass silk grid cloth strips on the fiber polymer cement mortar to connect every two benzene boards together;

[0026] 4. Spray fiber polymer cement mortar on the surface of the treated polystyrene board as a protective ...

Embodiment 2

[0036] 1. The polystyrene board and the treated wall are connected by mechanical fasteners, and the node structure of the polystyrene board adopts the form of staggered joints;

[0037] 2. After the polystyrene board is pasted on the entire wall, a horizontal grid joint is set on the upper and lower edges of each layer of windows with a depth of 3 cm, and then treated with waterproof caulking ointment or sealing strip grid seam;

[0038] 3. At the lap joint, the polystyrene board has a downward concave platform within a width of 2 cm from the edge of the board, and its depth is 3 mm. Use fiber polymer cement mortar to coat every two polystyrene boards. In the groove of the connection, paste alkali-resistant glass silk grid cloth strips on the fiber polymer cement mortar, and connect every two polystyrene boards together;

[0039] 4. Spray fiber polymer cement mortar on the surface of the treated polystyrene board as a protective layer, with a thickness of 3 mm;

[0040] 5. S...

Embodiment 3

[0050] 1. The polystyrene board and the treated wall are connected by the joint use of polymer cement mortar and mechanical fixing parts, and the joint structure of the polystyrene board adopts the form of staggered joints;

[0051] 2. After the polystyrene board is pasted on the entire wall, a horizontal grid joint is set on the upper and lower edges of each layer of windows with a depth of 3 cm, and then treated with waterproof caulking ointment or sealing strip grid seam;

[0052] 3. At the lap joint, the polystyrene board has a downward concave platform within a width of 2 cm from the edge of the board, and its depth is 4 mm. Use fiber polymer cement mortar to coat every two polystyrene boards. In the groove of the joint, paste alkali-resistant glass silk grid cloth strips on the fiber polymer cement mortar to connect every two benzene boards together;

[0053] 4. Spray fiber polymer cement mortar on the surface of the treated polystyrene board as a protective layer, with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com