High-strength impermeable anti-freezing concrete and preparation method thereof

A technology of concrete and waste concrete, which is applied in the field of building materials, can solve the problems of low concrete compressive strength, small reduction of salt, etc., and achieve the effects of avoiding free water channels, reducing porosity, and alleviating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

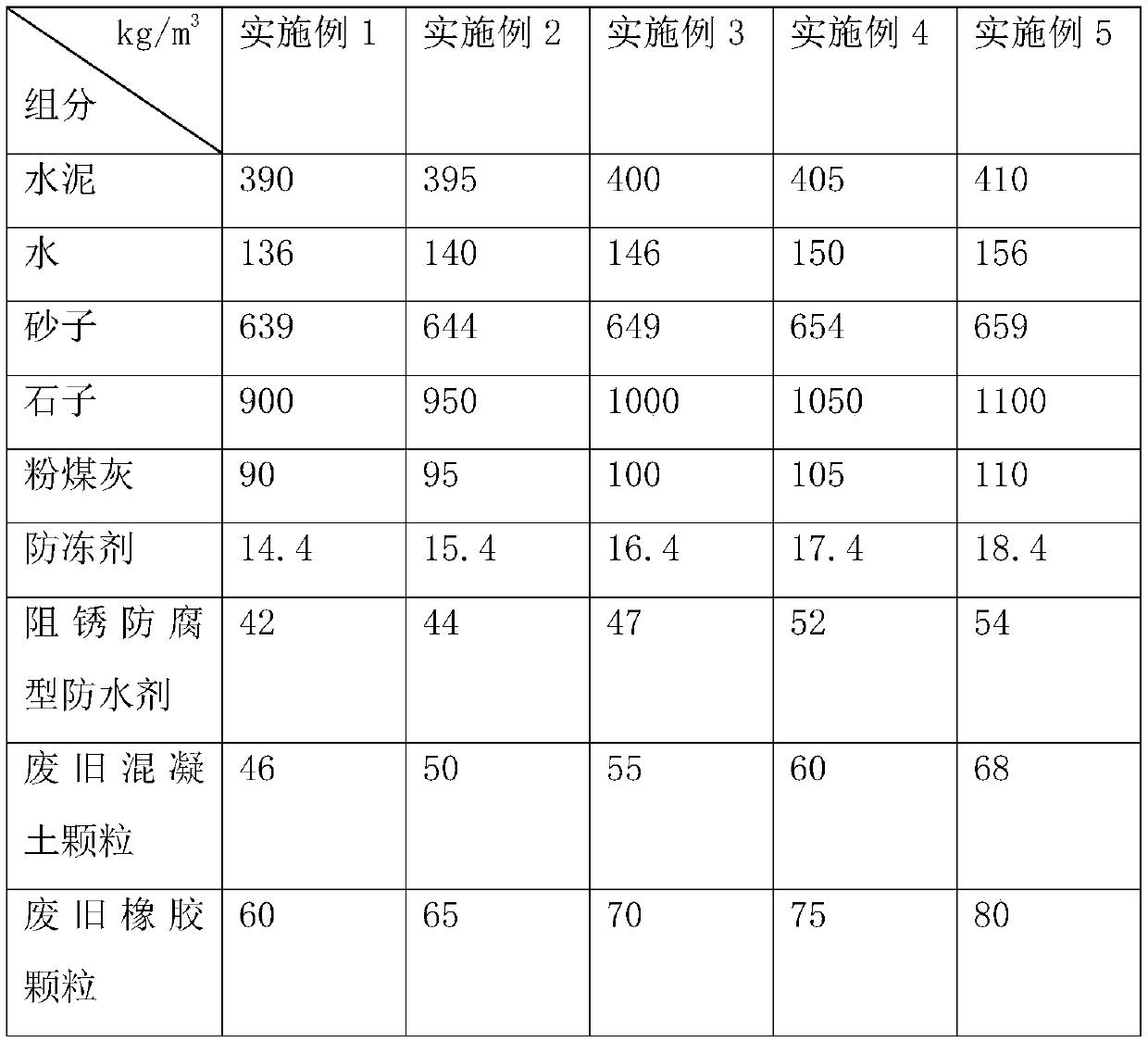

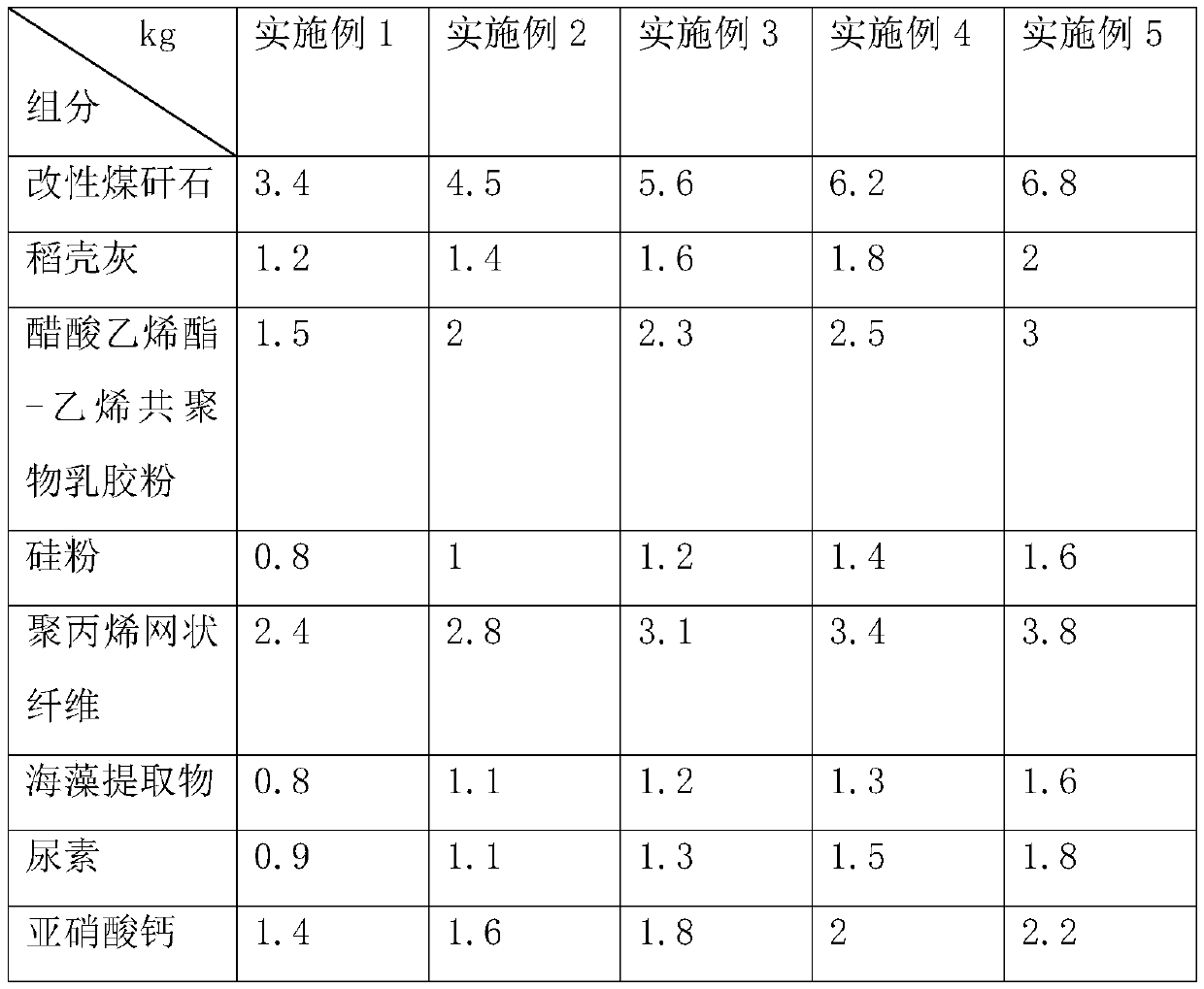

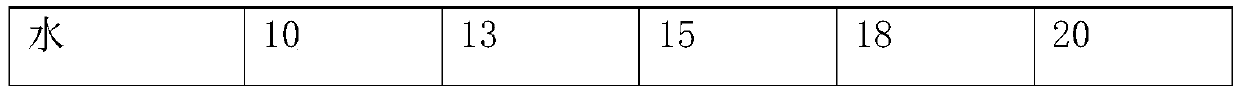

Examples

preparation example 1

[0038] Preparation Example 1: After crushing and pulverizing coal gangue, calcining at 1500°C for 5 hours, adding steel fibers, mixing evenly, adding diatomaceous earth and polyvinyl alcohol, mixing evenly, and preparing modified coal gangue powder, coal gangue and The mass ratio of steel fiber is 1:0.3, and the mass ratio of coal gangue, diatomite and polyvinyl alcohol is 1:0.4:0.3. The chemical composition of coal gangue is shown in Table 1.

[0039] Table 1 Chemical composition of coal gangue

[0040] w / % SiO 2

preparation example 2

[0041] Preparation example 2: After the coal gangue is crushed and pulverized, it is calcined at 1600°C for 4 hours, steel fibers are added, and after mixing evenly, diatomite and polyvinyl alcohol are added and mixed evenly to prepare modified coal gangue powder, coal gangue and The mass ratio of steel fiber is 1:0.4, and the mass ratio of coal gangue, diatomite and polyvinyl alcohol is 1:0.6:0.5. The chemical composition of coal gangue is shown in Table 1.

preparation example 3

[0042] Preparation Example 3: After the coal gangue is crushed and pulverized, it is calcined at 1700°C for 3 hours, steel fibers are added, and after mixing evenly, diatomite and polyvinyl alcohol are added and mixed uniformly to prepare modified coal gangue powder, coal gangue and The mass ratio of steel fiber is 1:0.5, and the mass ratio of coal gangue, diatomite and polyvinyl alcohol is 1:0.8:0.7. The chemical composition of coal gangue is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com