Low-temperature fume oxidizing and denitration method and system

A technology for low-temperature flue gas and denitrification, applied in chemical instruments and methods, separation methods, nitrogen oxides/oxyacids, etc., can solve problems such as increasing operating costs, achieve low operating costs, high efficiency, and adapt to working conditions powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

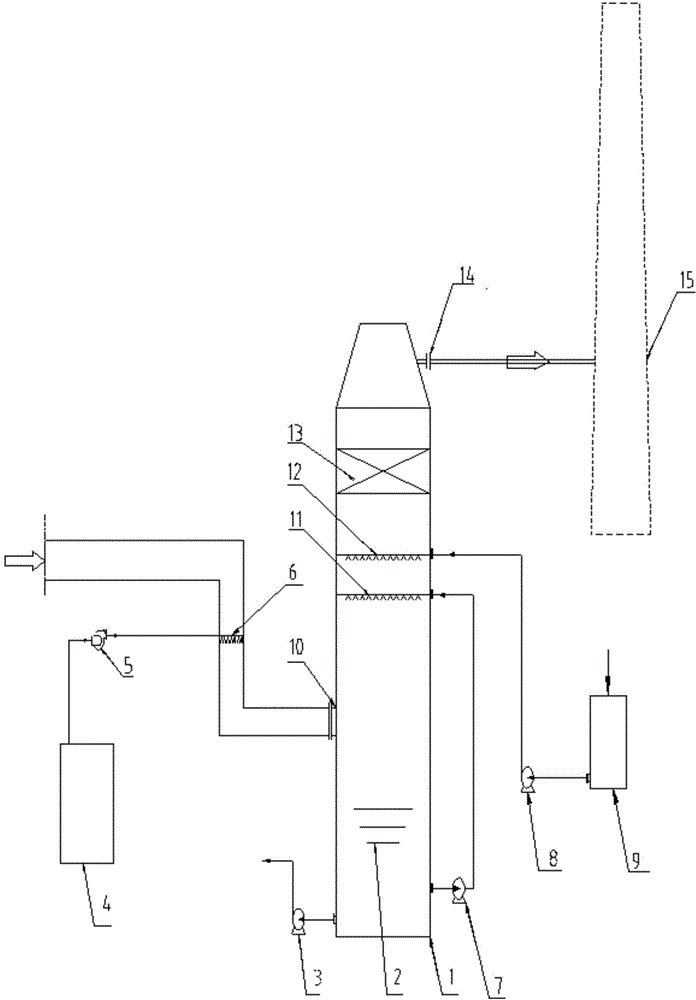

[0027] Take the sintering flue gas of a steel plant as an example. After the flue gas of the sintering machine is desulfurized by the limestone-gypsum wet method, the temperature of the flue gas with denitrification is about 50°C, and the chlorine dioxide gas generated by the chlorine dioxide gas generator 4 is blown into chlorine dioxide by the chlorine dioxide blower 5 In the gas mixer 6, the chlorine dioxide gas is fully mixed with the flue gas, and the mixed flue gas enters the oxidation tower 1. NO x The degree of oxidation is controlled at about 50%, and in oxidation tower 1, ClO 2 The gas oxidizes NO to easily absorbed NO 2 and N 2 o 3 . The calcium oxide absorption liquid is first stored in the absorption liquid tank 9, and the concentration of the calcium oxide absorption liquid is controlled. The absorption liquid is sprayed into the oxidation tower from the absorption liquid spray layer 12 through the absorption liquid spray pump 8, and the circulating absorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com