Freeze-thaw resistant cement hollow brick and preparation method thereof

A hollow brick, freeze-thaw-resistant technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of limiting the use range of cement hollow bricks, shortening the service life of cement hollow bricks, easy to freeze-thaw damage, etc. Improve freeze-thaw resistance, improve mechanical properties and chemical stability and other properties, improve mechanical strength and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

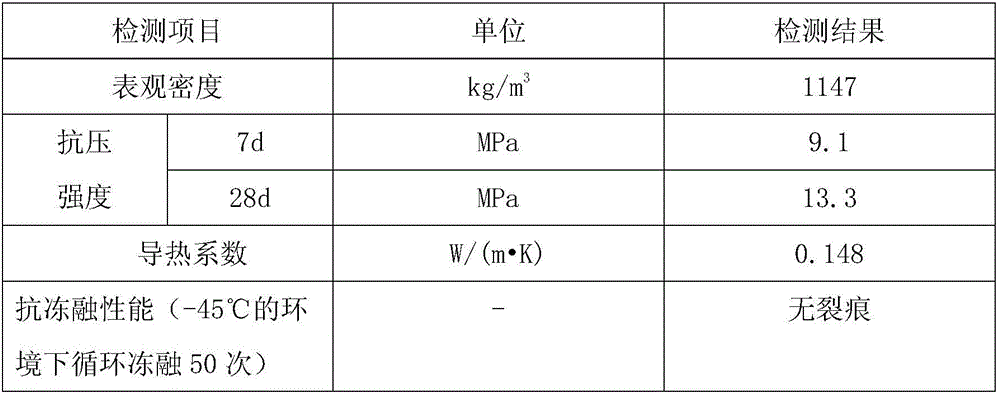

Examples

Embodiment Construction

[0014] A freeze-thaw resistant cement hollow brick, made of the following raw materials in weight (kg): Ordinary Portland cement 46, construction waste 25, mountain sand 18, sulfur-fixed ash 10, hornblende 7, silicon micropowder 12, barium carbonate 4.5, halloysite slag 10, copper mine tailings 6, coal gangue 9, electrolytic manganese slag 12, boron mud 8, loess 9, calcium nitrite 3, urea 4, sodium acetate 2.5, 1,3-propanediol 1.5 , Dibasic calcium phosphate 6, hydroxypropyl methylcellulose 7, appropriate amount of water.

[0015] A method for preparing a freeze-thaw resistant cement hollow brick, comprising the following steps:

[0016] (1) Mix coal gangue, electrolytic manganese slag, boron mud, and loess evenly, pulverize them, pass through a 60-mesh sieve, add an appropriate amount of water, stir well, make balls, and the particle size is controlled at 4mm, and then the prepared raw meal balls Dry at 105°C until the moisture content is below 3%, and then put the dried raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com