Process method for converting dry-method desulfurized fly ash into desulfurized gypsum

A technology of dry desulfurization ash and desulfurization gypsum, applied in chemical instruments and methods, inorganic chemistry, calcium/strontium/barium compounds, etc., can solve problems such as secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

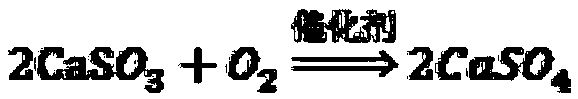

Method used

Image

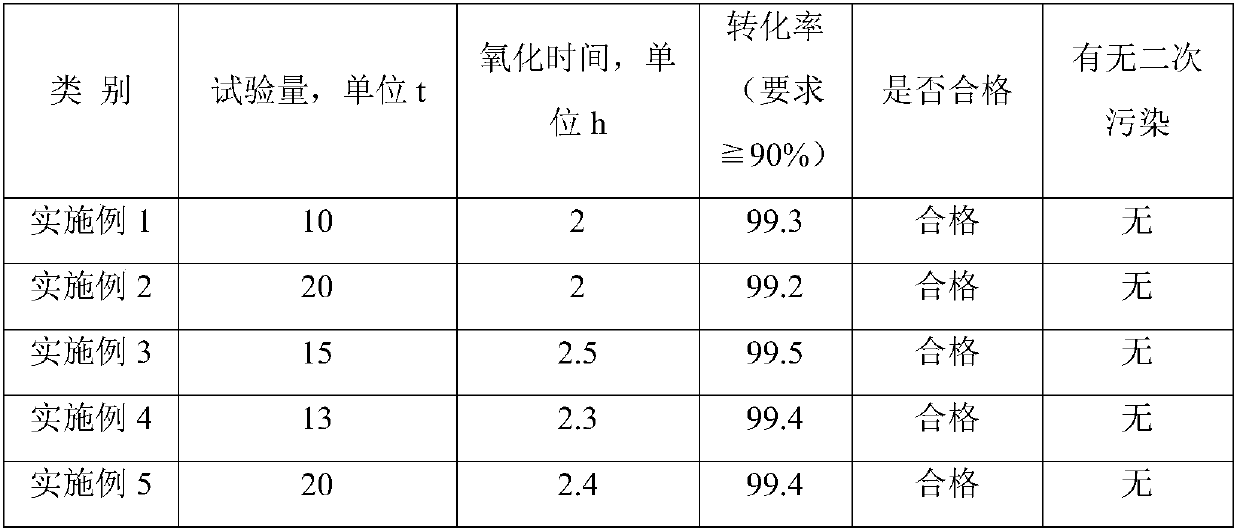

Examples

Embodiment 1

[0030] A process method for converting dry desulfurization ash into desulfurization gypsum. In this method, the dry desulfurization ash is placed in an oxidation tower with a stirring function, a certain amount of water is added, and the smoke from the head of the sintering machine after dust removal by the dust collector is introduced. After stirring for a certain period of time, solid-liquid separation is carried out, and the separated solid is further distilled, and the distilled waste liquid is returned to the oxidation tower for use, and the solid is transported out as desulfurized gypsum and used as a raw material for building materials.

[0031] The process flow is sintering machine flue gas, dry desulfurization ash, water → oxidation tower with stirring function → solid-liquid separation device → distillation device → desulfurization gypsum, the specific steps are as follows:

[0032] 1. Pass water into the oxidation tower with stirring function, and add the dry desulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com