Desulfurization wastewater zero-emission treatment device and method capable of collaborative demercuration

A desulfurization wastewater and treatment device technology, which is applied in the direction of gaseous effluent wastewater treatment, water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of high operating costs and non-standard emission of flue gas Hg, and achieve effective removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment, but protection scope of the present invention is not limited to this:

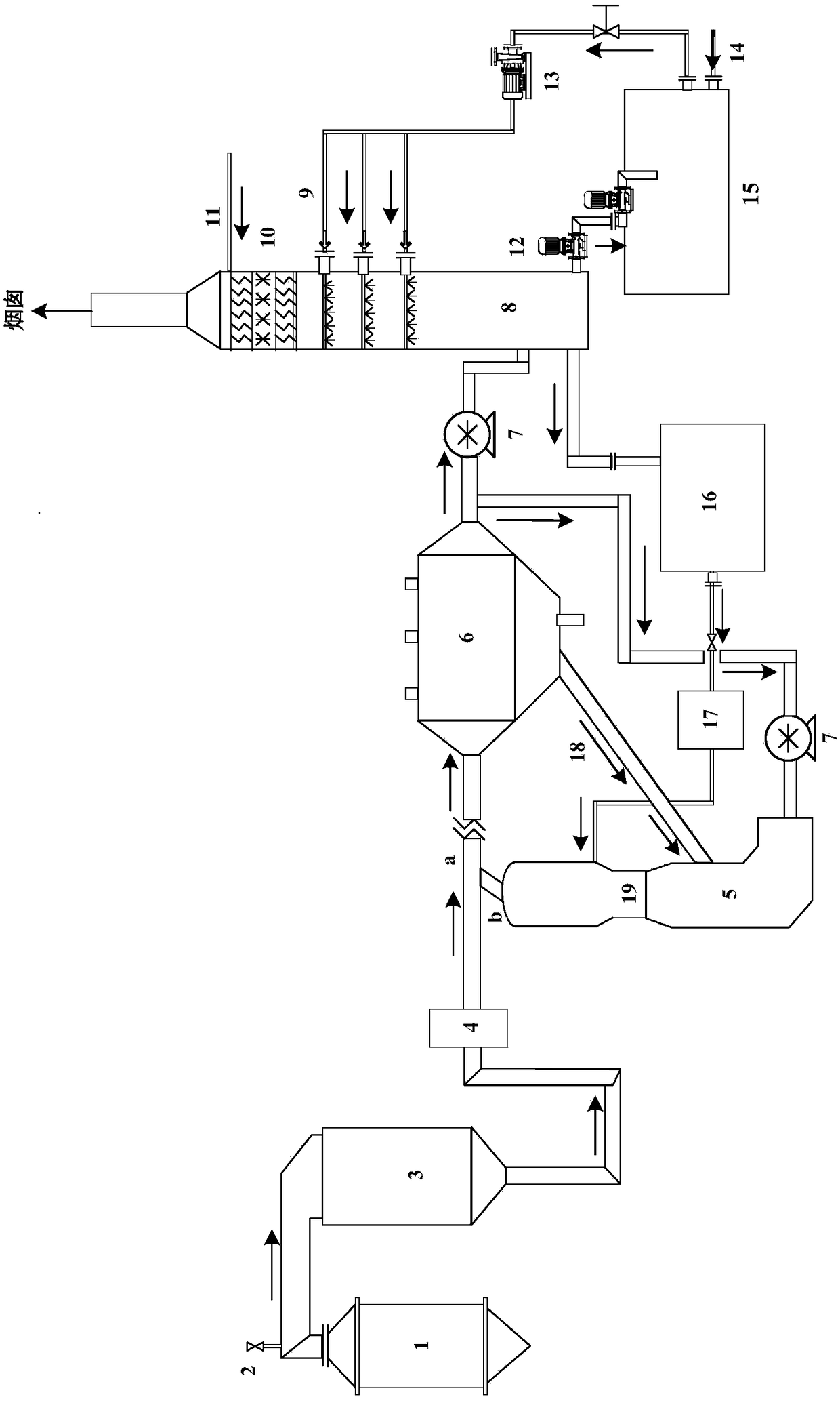

[0025] Such as figure 1 As shown, a zero-discharge treatment device for desulfurization wastewater with synergistic mercury removal, the device includes a coal-fired boiler (1), SCR denitrification (3), high-voltage electrostatic precipitator (6) and desulfurization tower (8), the described The coal-fired boiler (1) is connected to the air precipitator (4) through the SCR denitrification (3), and the air precipitator (4) is connected to the high-voltage electrostatic precipitator (6) through the pipeline a, and the high-voltage electric precipitator ( 6) An output end in the middle part is connected to the bottom of the desulfurization tower (8) through the fan (7); the output end at the bottom of the high-voltage electrostatic precipitator (6) passes through the fly ash chute (18) and the throat in turn (19) link...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com