Dye adsorbent and preparation method and application thereof

A technology of adsorbents and dyes, applied in chemical instruments and methods, adsorption of water/sewage treatment, water pollutants, etc., can solve the problems of low adsorption efficiency, achieve the effect of improved removal rate, simple treatment method, and good benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

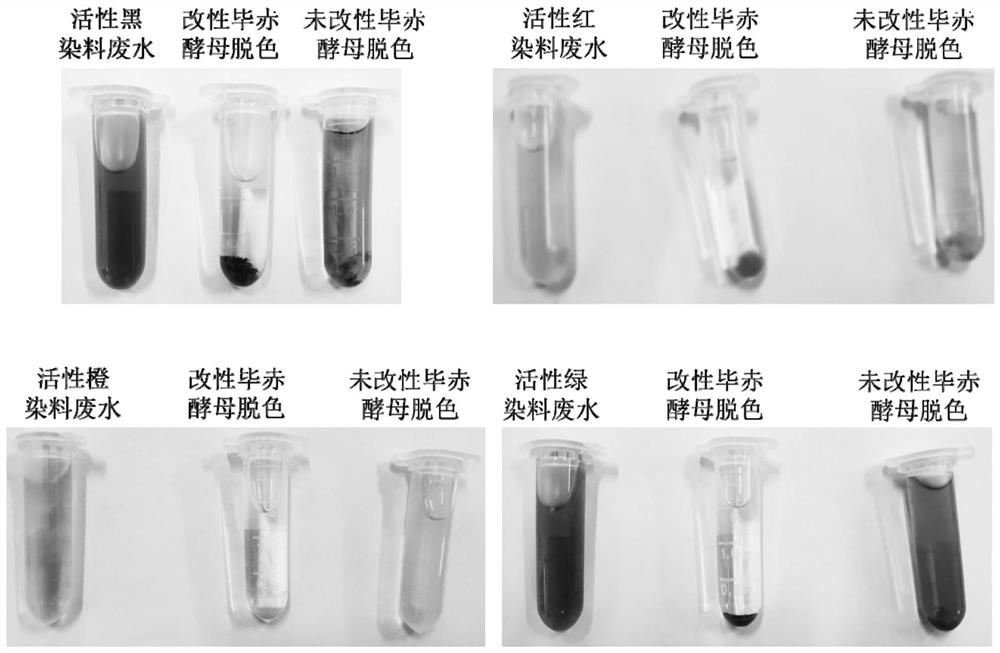

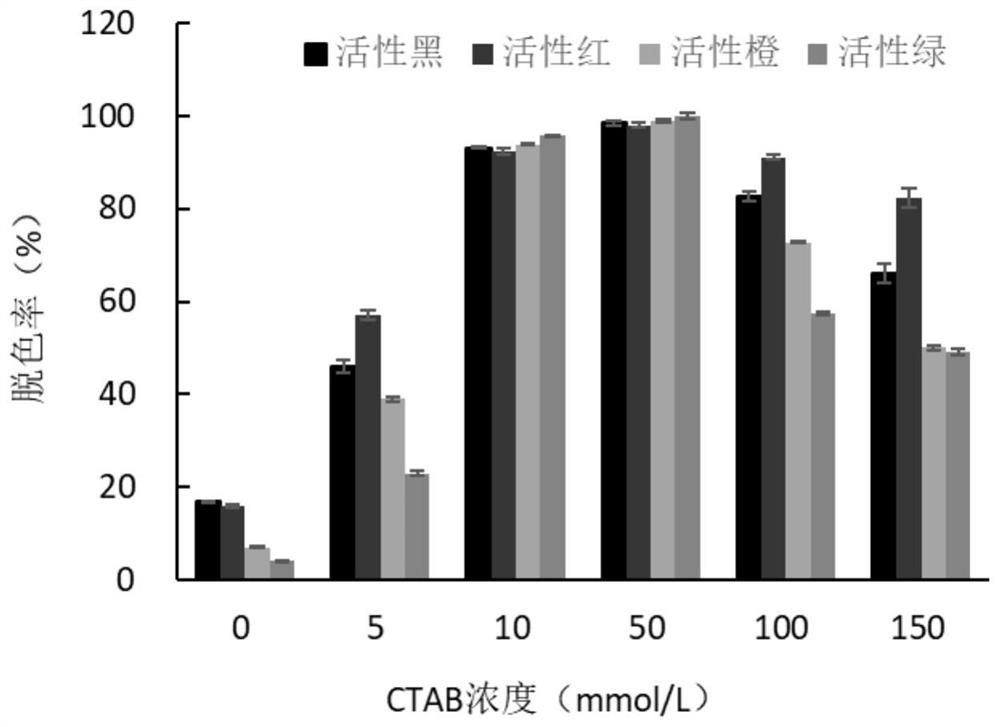

[0028] A preparation method of a dye adsorbent specifically includes the steps of: drying Pichia slag at 60° C. for 12 hours to constant weight; mixing dry Pichia slag with 10-50 mmol / L CTAB solution in a mass-volume ratio of 1: After mixing evenly at a ratio of 10, the modified Pichia pastoris was obtained after being treated in a warm bath at 30°C for 24 hours; the modified Pichia pastoris was recovered by centrifugation, washed twice with distilled water, and the surfactant CTAB was washed away, and dried at 60°C for 12 hours to Constant weight and pulverization to prepare dye biosorbent for treating dye wastewater.

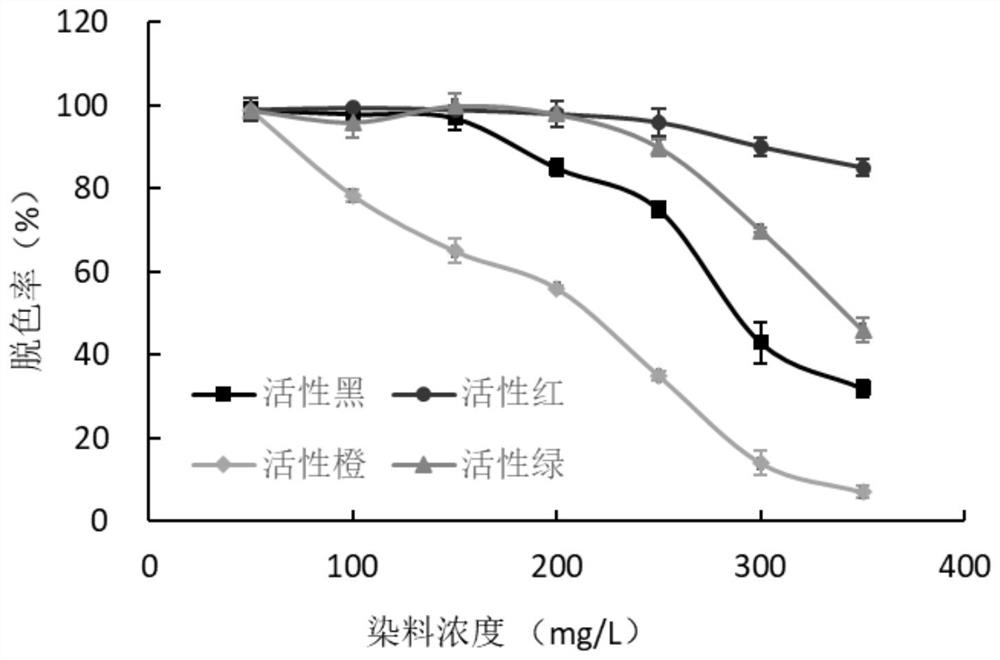

[0029] Take 1g of dye biosorbent and add it into 1L of reactive black dye wastewater with a concentration of 150mg / L while stirring. At normal temperature, pH 2-10 is adsorbed for 3-16h, and the maximum adsorption rate can reach 98.4%. The solid-liquid separation is carried out by centrifugation or precipitation separation, and the waste yeast residue is separ...

Embodiment 2

[0031] Take 1g of dye biosorbent and add it to 1L of reactive red dye wastewater with a concentration of 250mg / L while stirring. At normal temperature, pH2-10 carries out adsorption reaction for 1-16h, and the maximum adsorption rate can reach 97.8%. The solid-liquid separation is carried out by centrifugation or precipitation separation, and the waste yeast residue is separated to obtain treated effluent.

[0032] The preparation method of the dye biosorbent is the same as in Example 1.

Embodiment 3

[0034] Take 1g of dye biosorbent and add it into 1L of wastewater with a concentration of 50mg / L active orange dye while stirring. At room temperature, pH2-8 carries out adsorption reaction for 1-16h, and the maximum adsorption rate can reach 99.4%. The solid-liquid separation is carried out by centrifugation or precipitation separation, and the waste yeast residue is separated to obtain treated effluent.

[0035] The preparation method of the dye biosorbent is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com