Composite ceramsite prepared from water purification sludge and diatomite

A diatomaceous earth and sludge technology, which is applied in the production of clay products, ceramic products, and ceramic materials, can solve the problems of secondary pollution of the environment, and achieve the effects of reduced firing energy consumption, developed pore structure, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

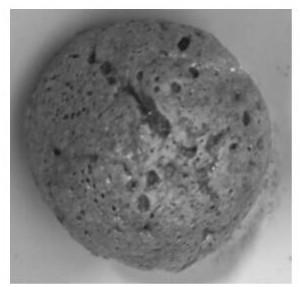

Image

Examples

Embodiment 1

[0018] This embodiment provides a kind of composite ceramsite prepared from water purification sludge and diatomite, calculated by weight ratio, its raw materials include:

[0019] 80 parts of water purification sludge;

[0020] 20 parts of diatomaceous earth;

[0021] 10 parts of calcium oxide.

[0022] (1) Raw material preparation

[0023] Dry the purified water sludge at a temperature of 110°C.

[0024] If the diatomite is the waste diatomite recovered from the brewery for filter aid, hydrothermal treatment of the waste diatomite: mix the diatomite with water evenly, put it in the reaction kettle, and put the reaction kettle at a constant temperature Heating in a blast drying oven for 6 h at a temperature of 160 °C, taking out the diatomite after the reaction was completed, and cooling to room temperature naturally. The organic matter in it can be carbonized by hydrothermal method, and the organic matter can be condensed into small spherical particles, so that the spent...

Embodiment 2

[0033] This embodiment provides a kind of composite ceramsite prepared from water purification sludge and diatomite, calculated by weight ratio, its raw materials include:

[0034] 80 parts of water purification sludge;

[0035] 20 parts of diatomaceous earth;

[0036] 10 parts of calcium oxide.

[0037] Preparation steps:

[0038] (1) Raw material preparation

[0039] Dry the purified water sludge at a temperature of 110°C.

[0040] Diatomite is the waste diatomite recovered from the brewery for filter aid, and the waste diatomite is treated with hydrothermal method: the diatomite and water are evenly mixed, placed in the reactor, and the reactor is placed in a constant temperature drum Heat in an air drying oven for 6 h at a temperature of 160 °C. After the reaction is complete, take out the diatomite and let it cool down to room temperature naturally.

[0041] According to the above weight ratio, the pretreated water purification sludge, diatomaceous earth and calcium ...

Embodiment 3

[0049] This embodiment provides a kind of composite ceramsite prepared from water purification sludge and diatomite, calculated by weight ratio, its raw materials include:

[0050] 90 parts of water purification sludge;

[0051] 20 parts of diatomaceous earth;

[0052] 15 parts of calcium oxide.

[0053] Preparation steps:

[0054] (1) Raw material preparation

[0055] Dry the purified water sludge at a temperature of 110°C.

[0056] Diatomite is the waste diatomite recovered from the brewery for filter aid, and the waste diatomite is treated with hydrothermal method: the diatomite and water are evenly mixed, placed in the reactor, and the reactor is placed in a constant temperature drum Heat in an air drying oven for 6 h at a temperature of 160 °C. After the reaction is complete, take out the diatomite and let it cool down to room temperature naturally.

[0057] According to the above weight ratio, the pretreated water purification sludge, diatomaceous earth and calcium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com