Method for preparing high-temperature CO2 adsorbent by utilizing dredging dianchi lake sediment

A CO2 and adsorbent technology, which is used in the preparation of CO2 adsorbents to achieve the effects of high CO2 adsorption performance and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

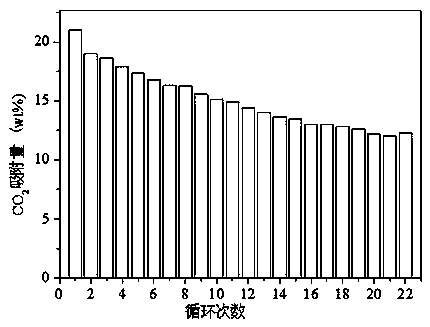

Embodiment 1

[0020] Example 1: The preparation of high-temperature CO by dredging the bottom mud of Dianchi Lake 2 The adsorbent method comprises the following steps:

[0021] (1) Take the dehydrated dredged Dianchi Lake sediment, filter and wash it with deionized water for 3 times, remove branches, weeds and other impurities, dry it in an oven until the water content is 2%, and grind it to powder;

[0022] (2) According to the ratio of adding 20mL of acid mixture per 1 g of step (1) powder, add step (1) powder into hydrochloric acid-nitric acid mixture (hydrochloric acid-nitric acid mixture is hydrochloric acid and nitric acid in a volume ratio of 1:1 prepared by mixing the proportions), heated to 80°C, condensed and refluxed for 24 hours, removed the supernatant, centrifuged and washed with deionized water until the supernatant was neutral, and then dried in an oven at 100°C until the water content was 2%. , cooled and ground to obtain SiO-containing 2 samples, SiO in samples 2 The co...

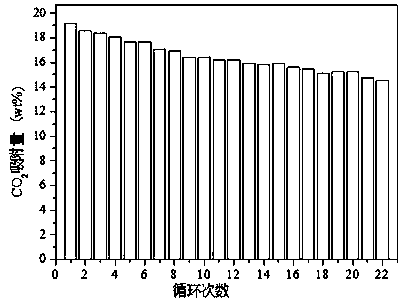

Embodiment 2

[0026] Example 2: The preparation of high-temperature CO by dredging the bottom mud of Dianchi Lake 2 The adsorbent method comprises the following steps:

[0027] (1) Take the dehydrated dredged Dianchi Lake sediment, filter and wash it with deionized water for 4 times repeatedly to remove impurities such as branches and weeds, put it in an oven to dry until the water content is 1%, and grind it to powder;

[0028] (2) According to the ratio of adding 30mL of acid mixture per 1 g of step (1) powder, add step (1) powder into hydrochloric acid-nitric acid mixture (hydrochloric acid-nitric acid mixture is hydrochloric acid and nitric acid in a volume ratio of 3:1 prepared by mixing the proportions), heated to 85°C, condensed and refluxed for 20 hours, removed the supernatant, centrifuged and washed with deionized water until the supernatant was neutral, and then dried in an oven at 105°C until the water content was 2%. , cooled and ground to obtain SiO-containing 2 samples, SiO i...

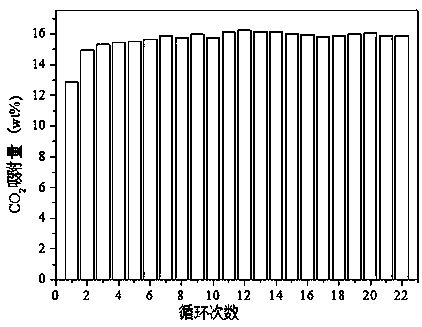

Embodiment 3

[0032] Example 3: The preparation of high-temperature CO by dredging the bottom mud of Dianchi Lake 2 The adsorbent method comprises the following steps:

[0033] (1) Take the dehydrated dredged bottom mud of Dianchi Lake, filter and wash it with deionized water for 5 times repeatedly to remove impurities such as branches and weeds, put it in an oven to dry until the water content is 2%, and grind it to powder;

[0034] (2) According to the ratio of adding 25mL of acid mixture per 1g of step (1) powder, add step (1) powder into hydrochloric acid-nitric acid mixture (hydrochloric acid-nitric acid mixture is hydrochloric acid and nitric acid in a volume ratio of 4:1 Proportionally mixed), heated to 90°C, condensed and refluxed for 15 hours, removed the supernatant, centrifuged with deionized water until the supernatant was neutral, and then dried in an oven at 85°C until the water content was 1%. Cooling and grinding to obtain SiO-containing 2 samples, SiO in samples 2 conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com