Aluminum alloy lifting scaffold

A technology for lifting scaffolding and aluminum alloys, which is applied to scaffolding supported by housing structures, housing structure supports, housing structure supports, etc. The effect of high load and repeated use rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

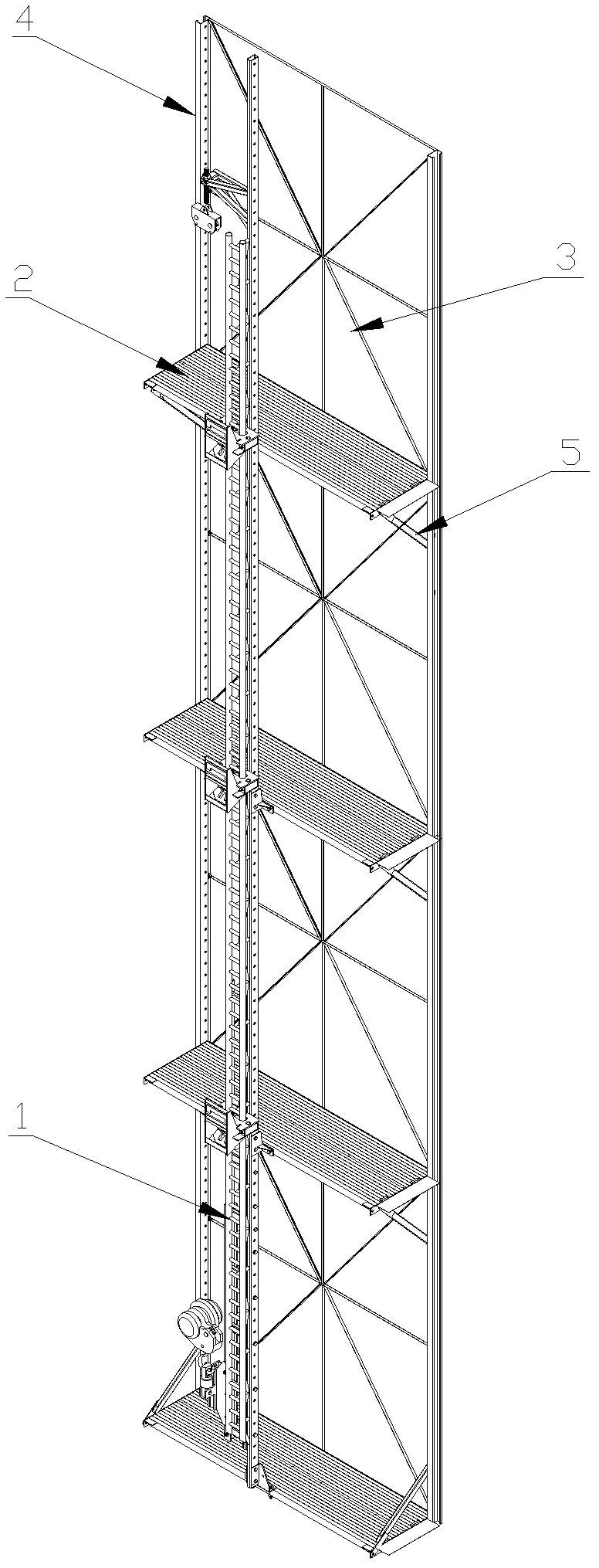

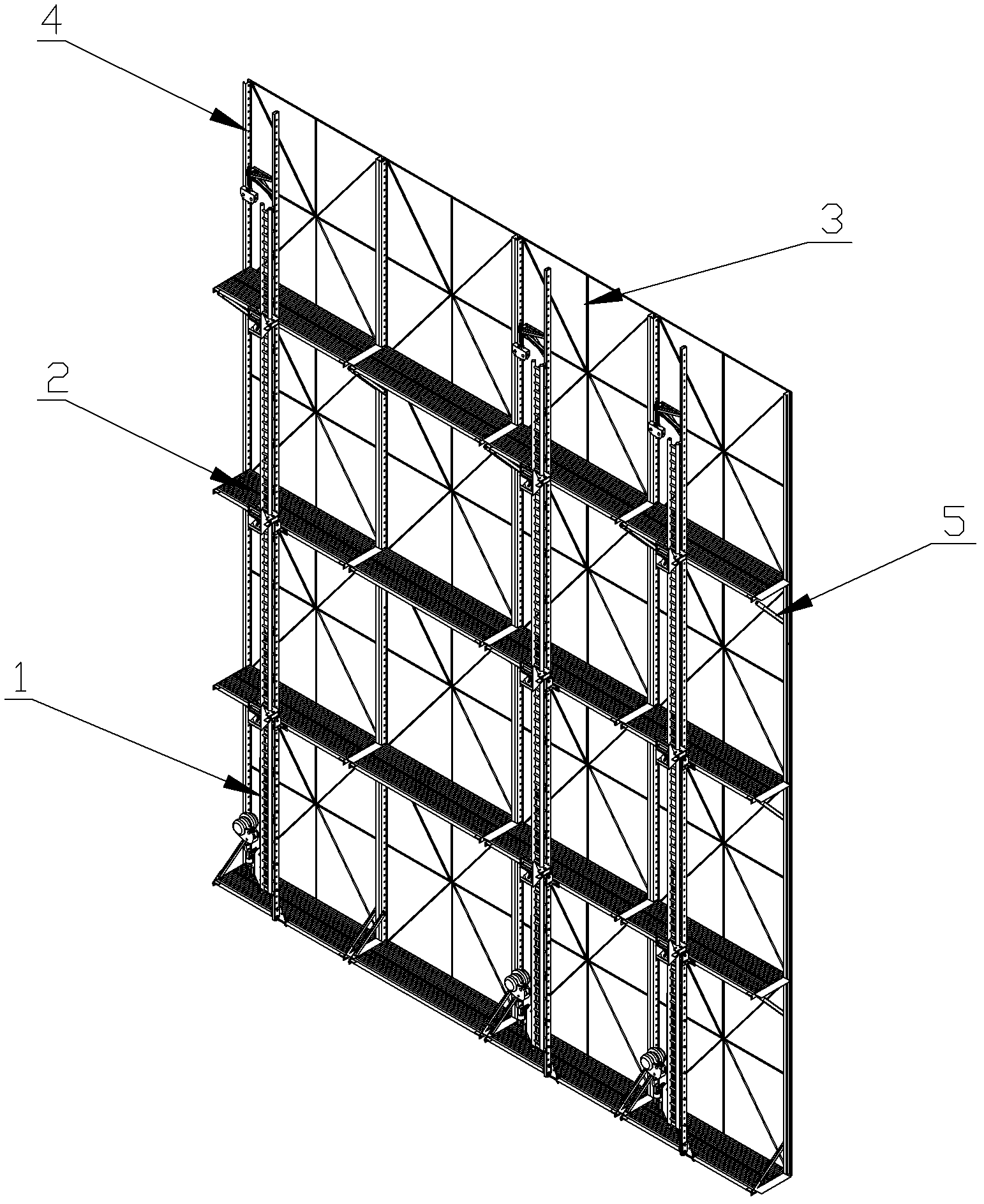

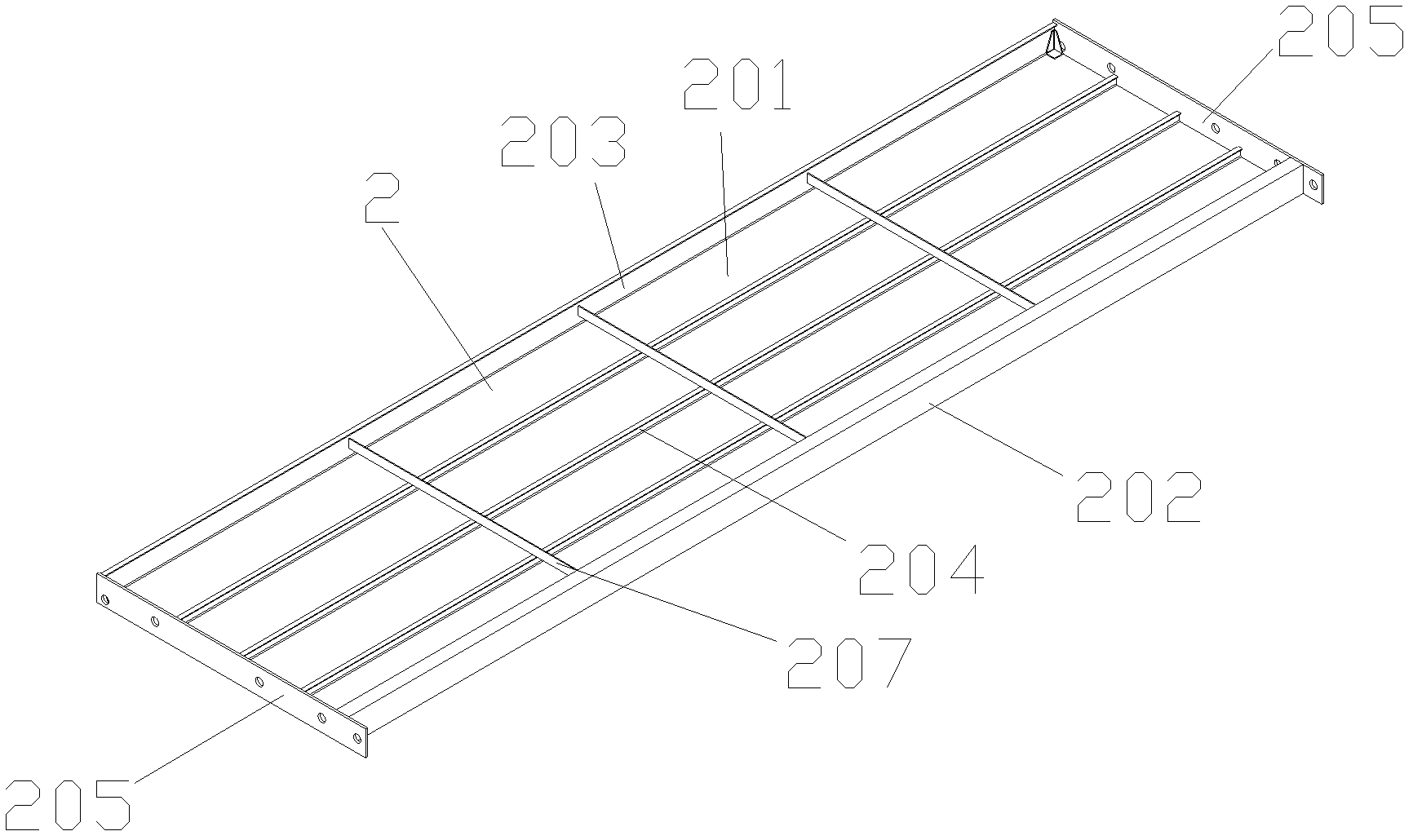

[0042] Such as figure 1 , figure 2 As shown, the aluminum alloy lifting scaffold of the present invention includes a lifting attachment device 1 , a protective net 3 , a pole 4 and a scaffolding board 2 . The scaffolding board 2 is fixed on the vertical pole 4, the lifting attachment device 1 can be fixed on the scaffolding board 2 or the vertical pole 4, and the protective net 3 is fixedly connected with the vertical pole 4. The lifting attachment device 1 is used for lifting the scaffold. When the scaffold stays on the designated floor, it can be supported on the designated floor. The specific structure of the lifting attachment device 1 is the prior art, and will not be repeated here. People can stand on the scaff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com