Patents

Literature

51results about How to "Easy and quick assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

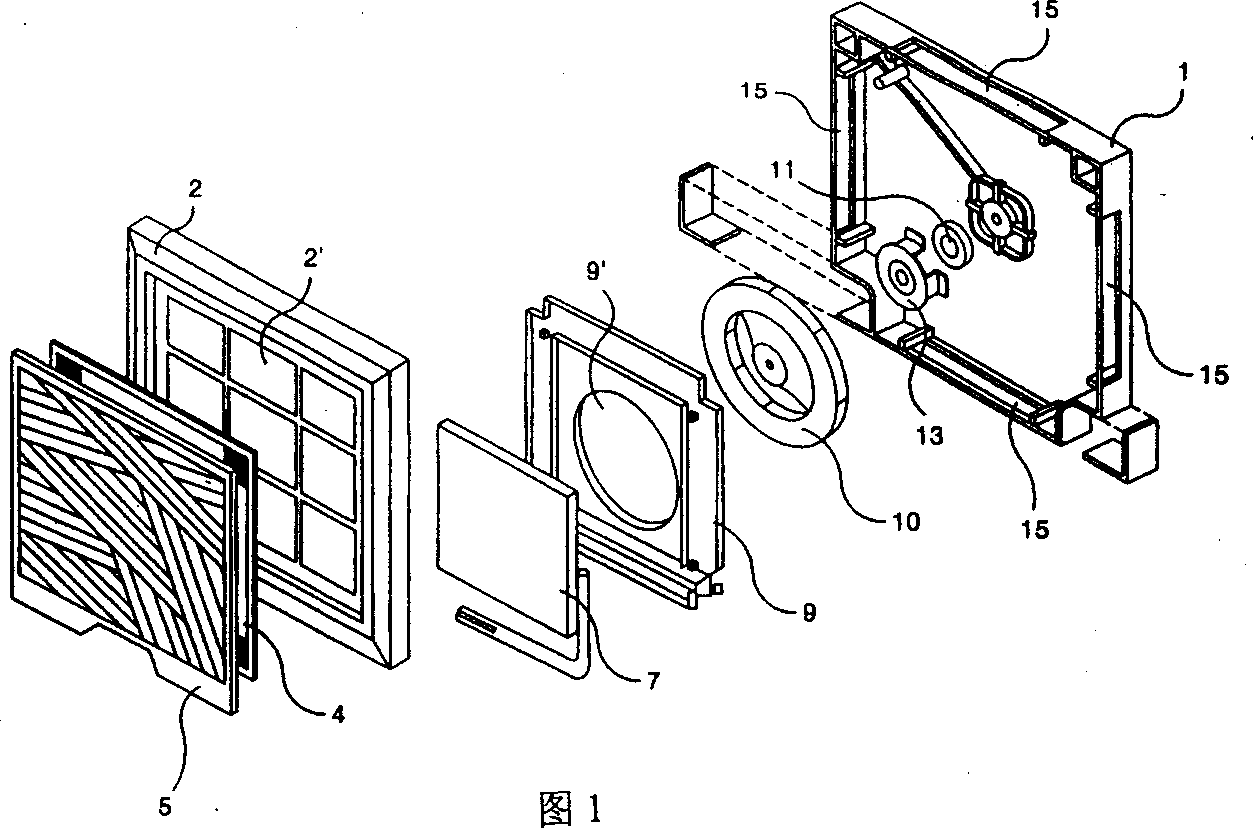

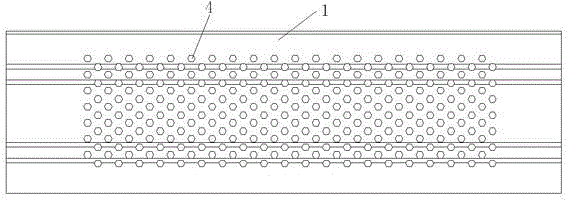

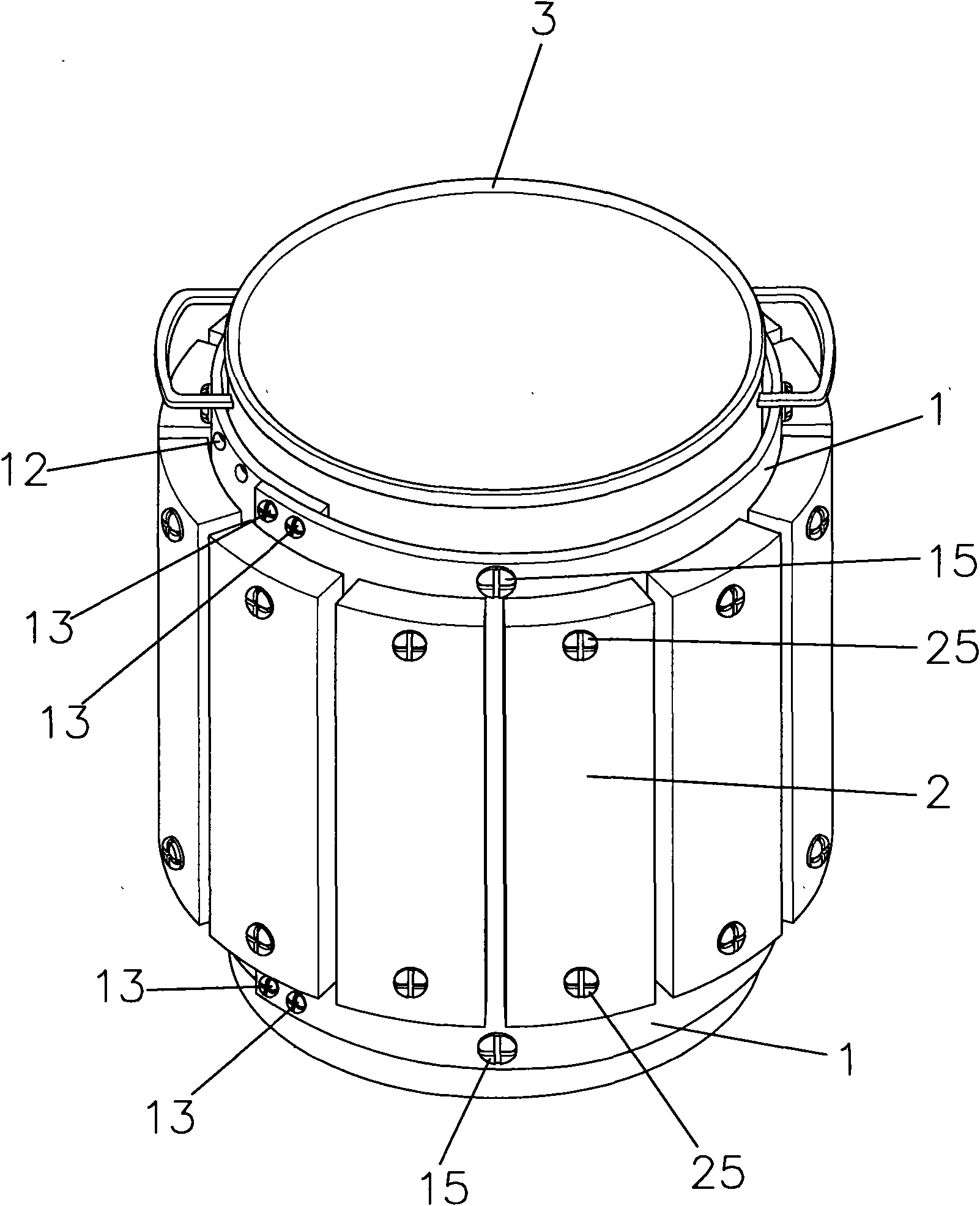

LED screen

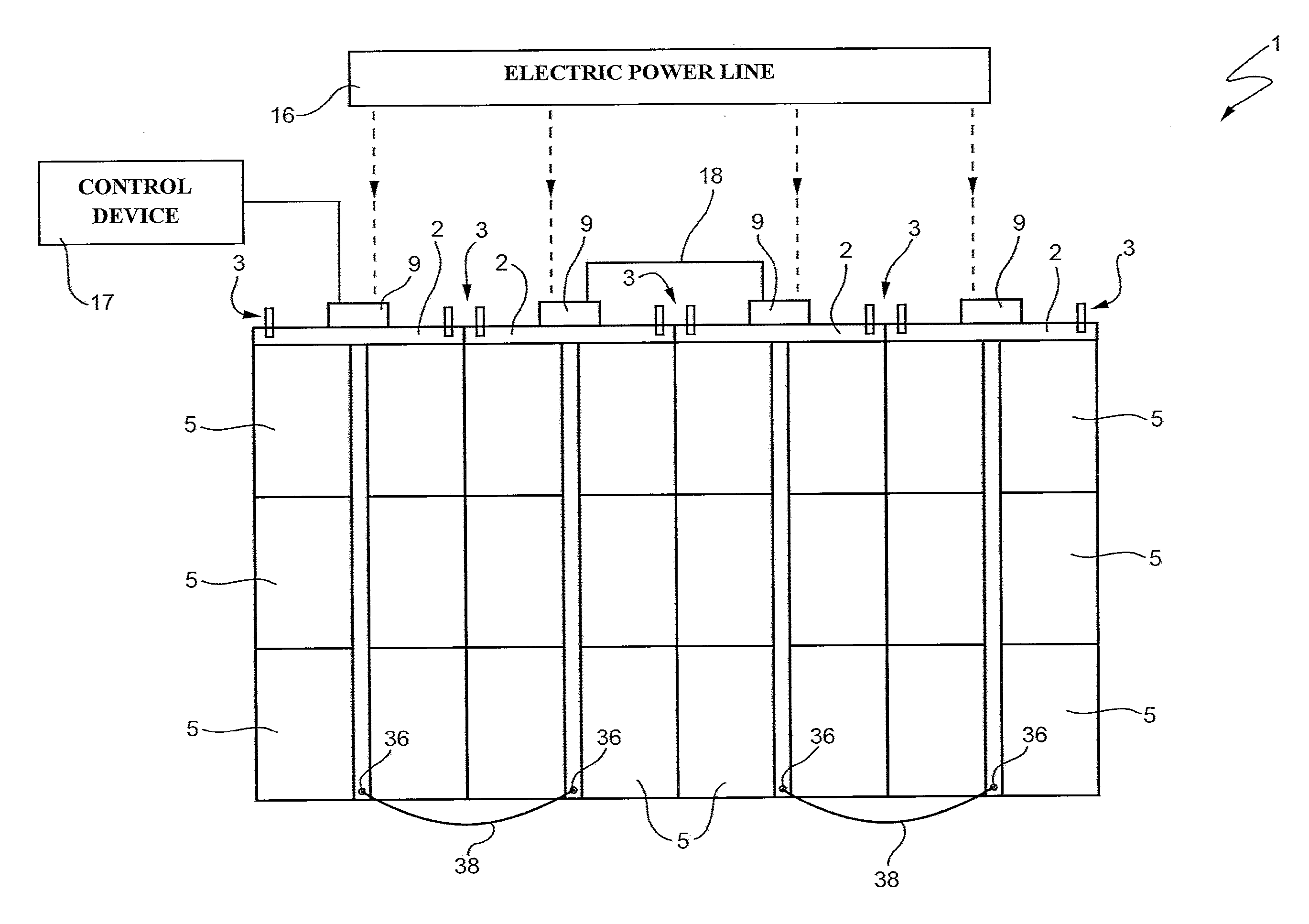

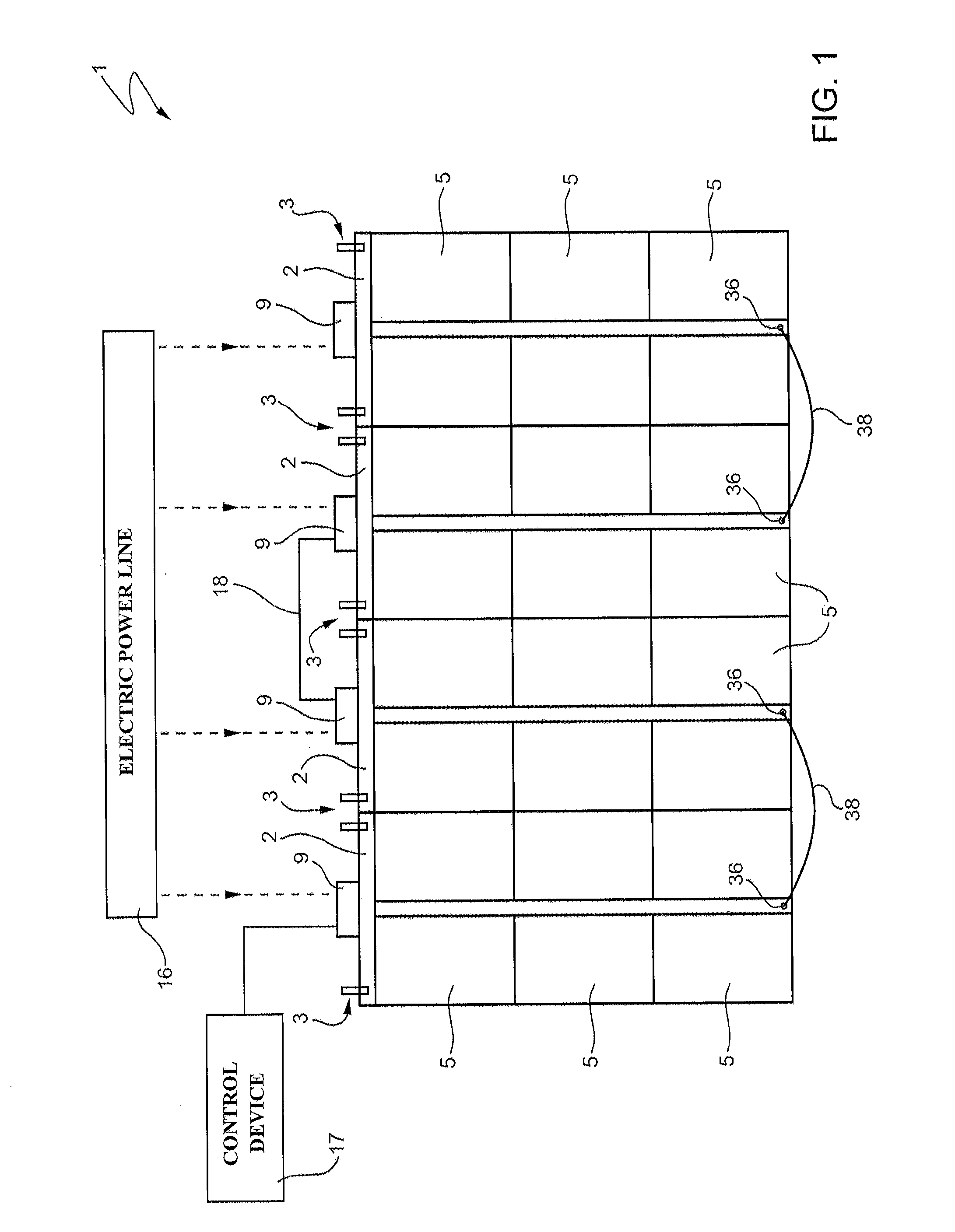

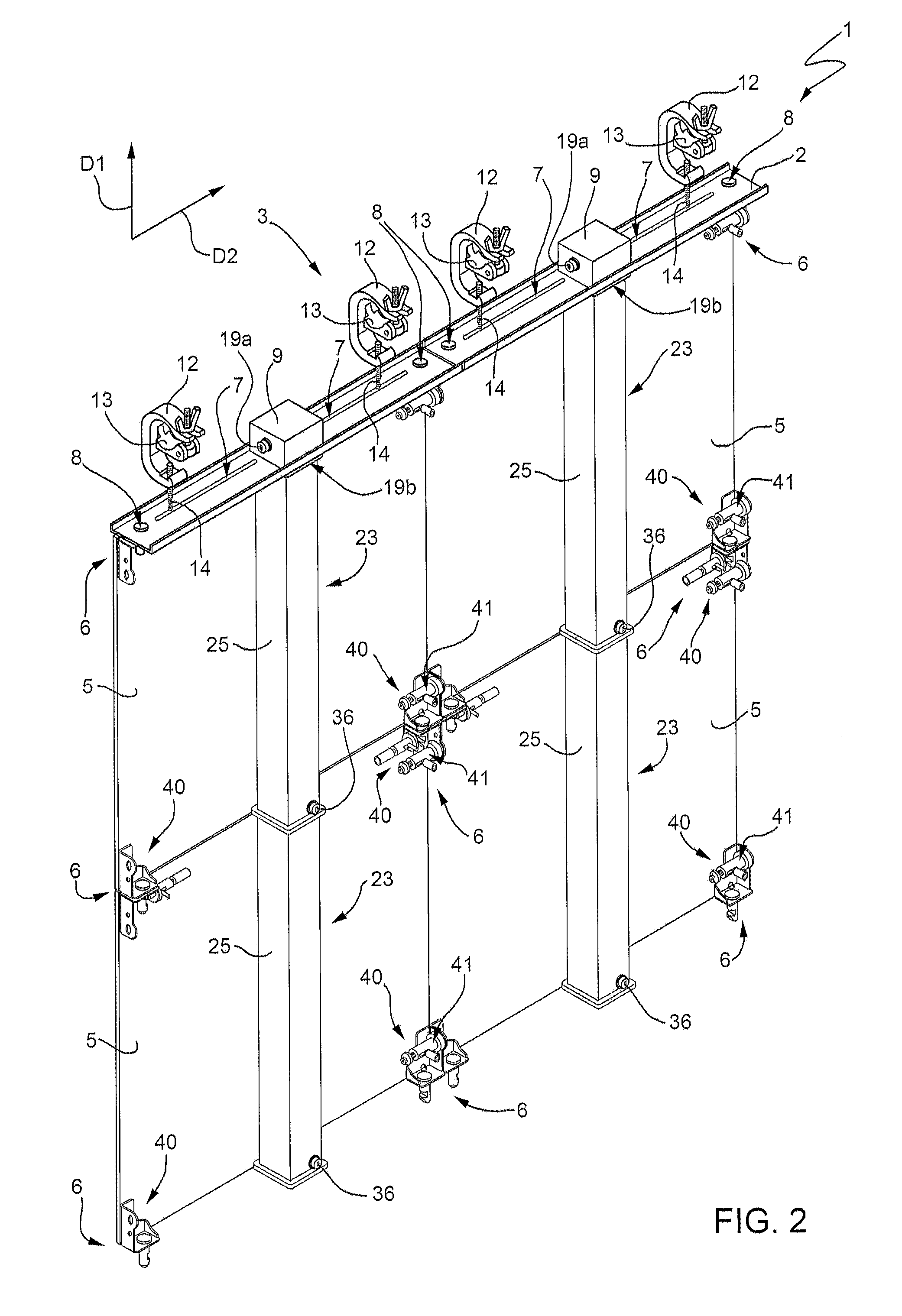

InactiveUS20120062540A1Easy and quick assemblyEasy and fast assemblyCathode-ray tube indicatorsInput/output processes for data processingEngineeringData lines

A LED screen having a number of interconnected LED panels; each LED panel having a connecting module, in turn having an electric power line connectable to an electric power source, and a data line; the connecting module having a first connecting end and a second connecting end, which are fixed rigidly to the LED panel and have a number of male contacts and a number of female contacts respectively; the first connecting end being connectable to a respective second connecting end of another LED panel, and the second connecting end being connectable to a respective first connecting end of another LED panel.

Owner:CLAY PAKY

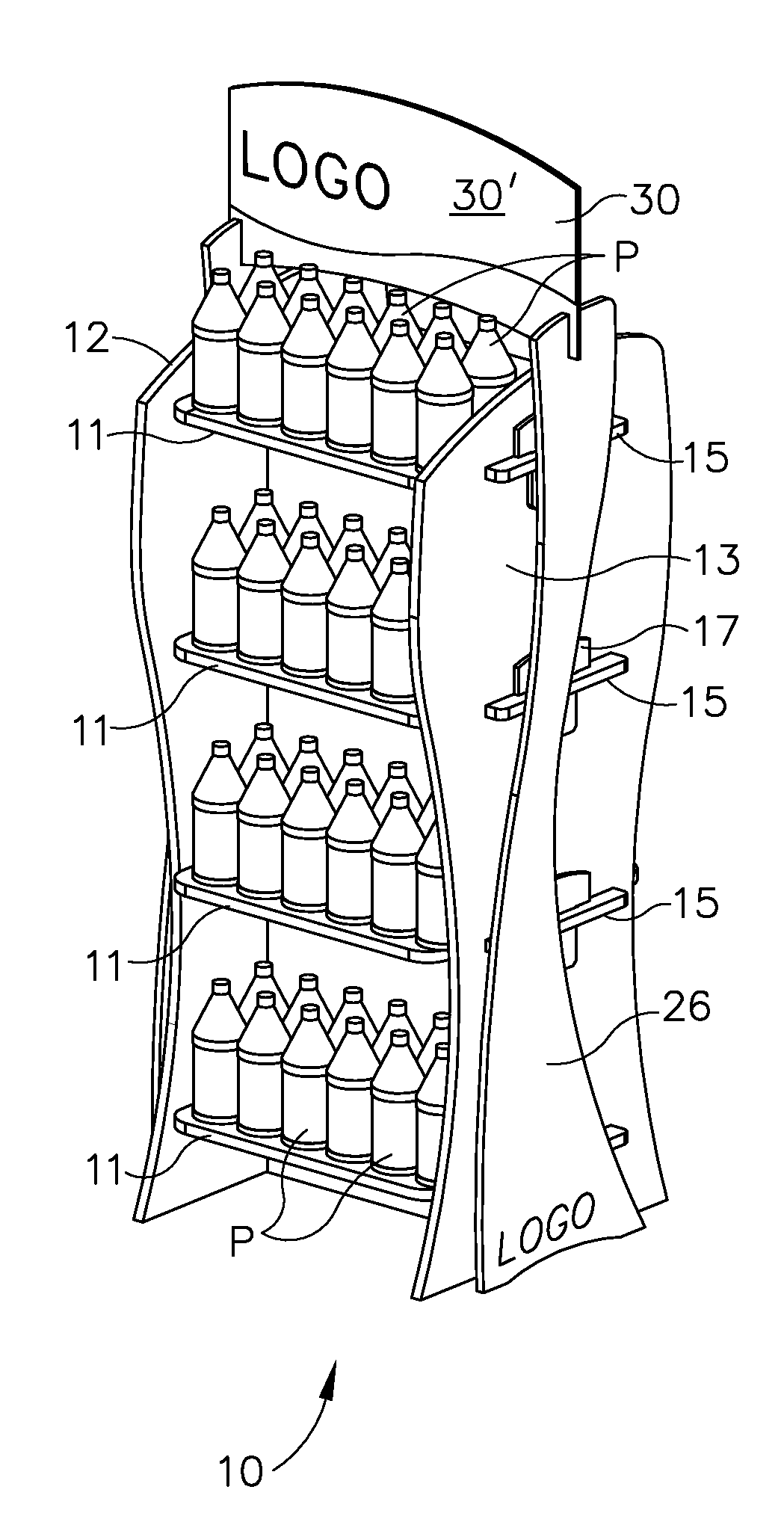

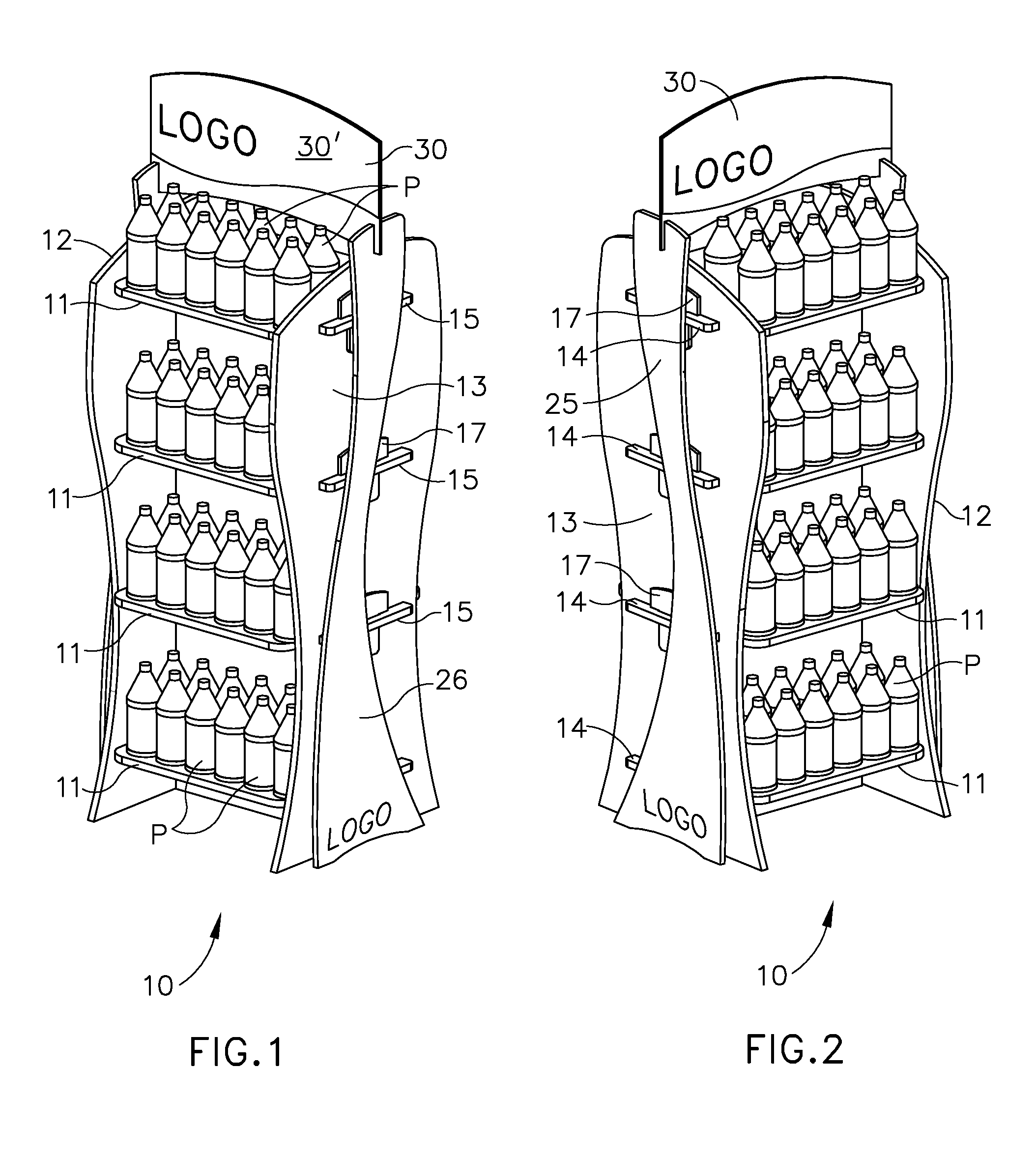

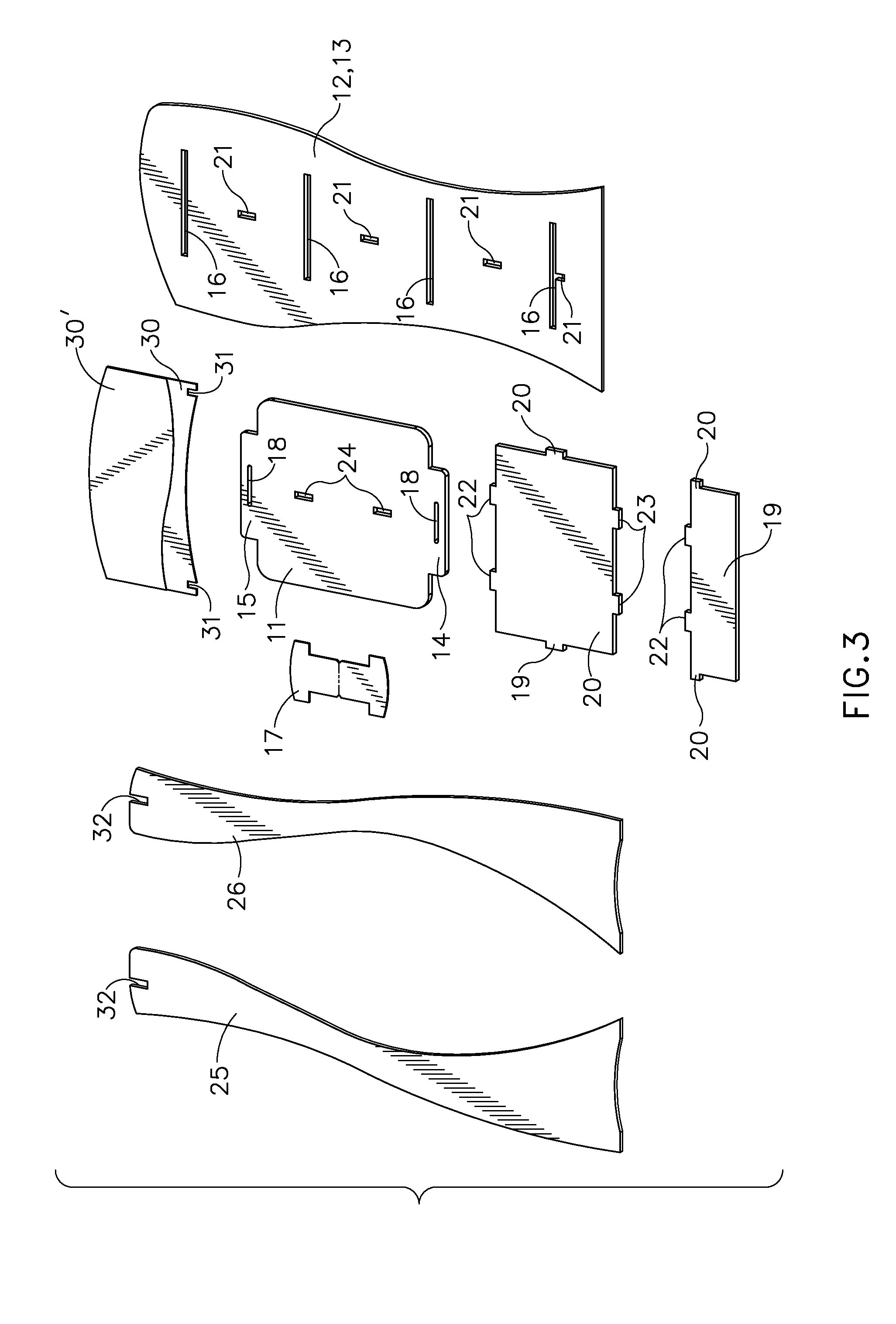

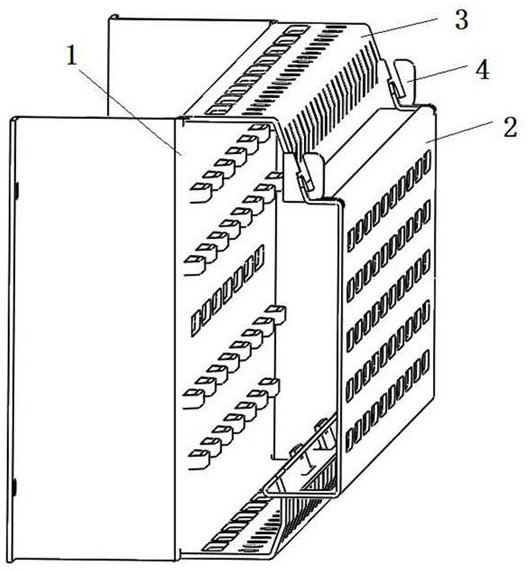

Multi-ply laminated corrugated display rack with a back wall

ActiveUS20130062293A1Easy and quick assemblyEasy and fast assemblyFurniture joining partsRacksEngineeringSurface plate

A freestanding display rack is made of existing fiber recycling chains and can be shipped in a knocked-down flattened condition. The display rack comprises a pair of spaced apart side panels each having an outer surface, and an inner surface facing an opposite side panel. A back panel is attached to the side panels by interfitting tabs and notches along adjacent edges of the back panel and the side panels. A plurality of shelves extending between and supported at their opposite ends on the side panels by mechanical interlocking means engaged between the shelves and the side panels. The mechanical interlocking comprises channels formed in the inner surface of each the side panel, and depending flanges on opposite side edges of each the shelf engaged in a respective the channel. A graphics header extends above the shelves and side panels.

Owner:INT PAPER CO

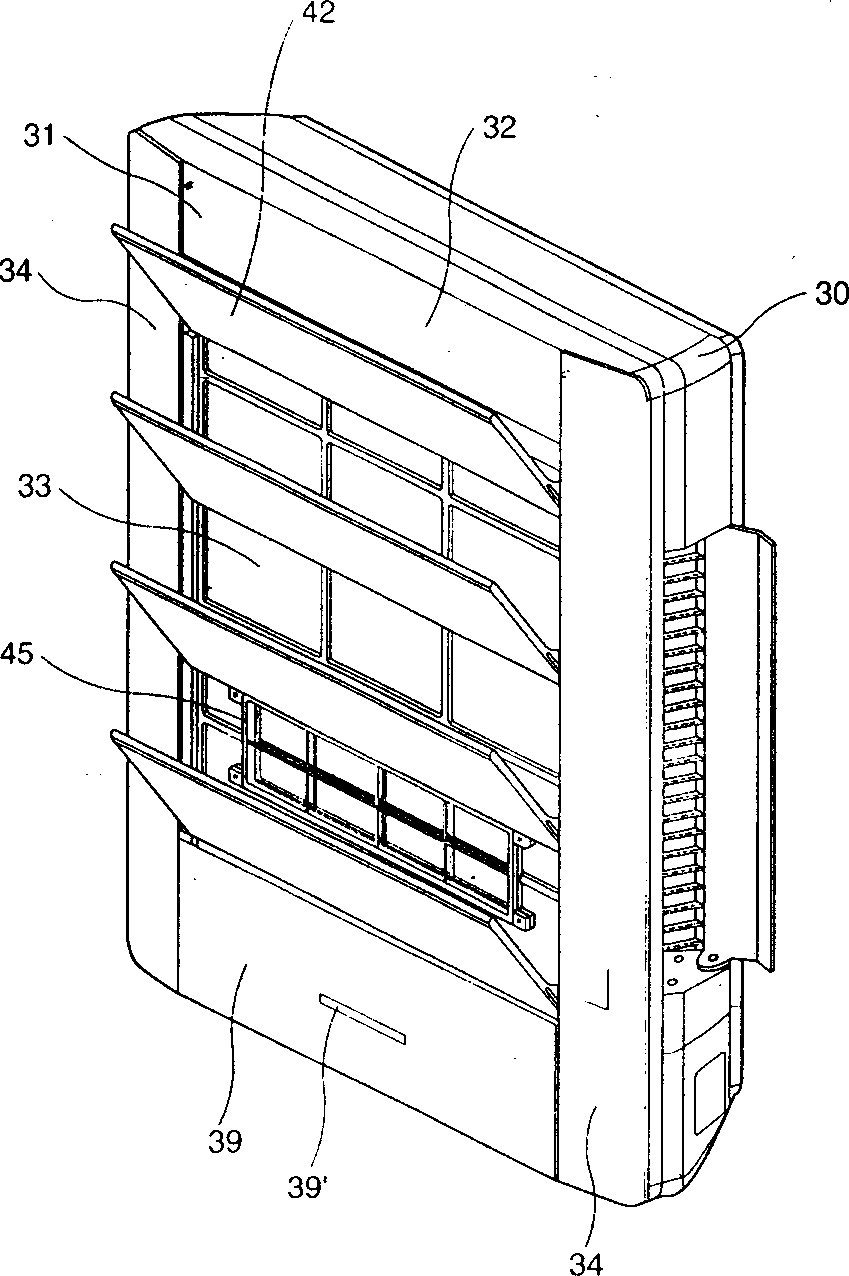

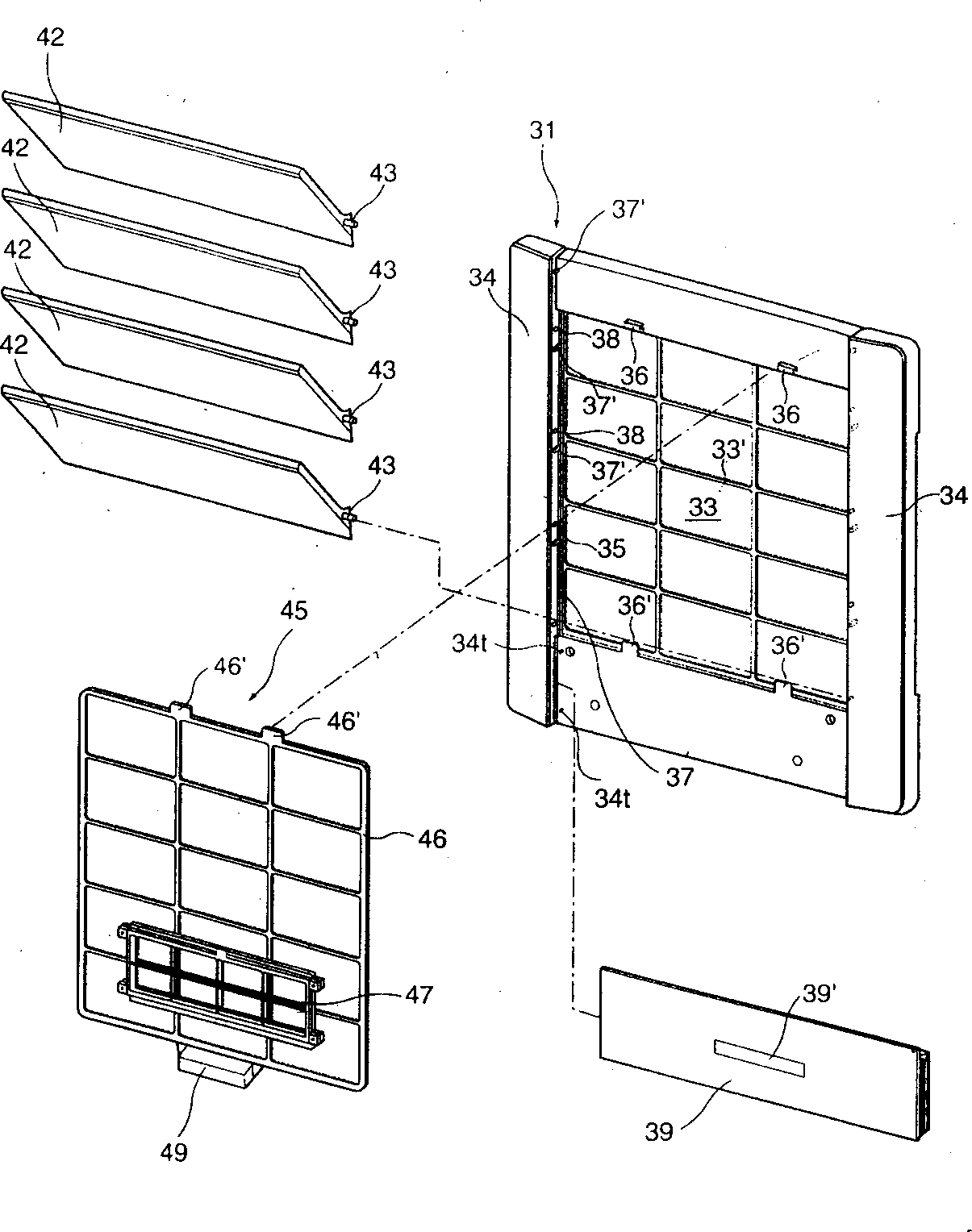

Front plate unit of split air conditioner

InactiveCN1357720ABeautiful appearanceEasy to disassembleLighting and heating apparatusSpace heating and ventilation detailsEngineeringFuselage

The present invention discloses a front plate unit of split air conditioner, and the center part of the front plate has inhaling through hole for holding air purifying filter. There are raised decorative plates at the two ends of the front plant and embedded part installed to the bottom of the grille and between the raised decorative parts. All the surfaces of the grille, the bottom and the decorative plates from one continuous plane. The filter is set inside the space between the front plate and the grille and is one easy-to-assembly and easy-to-disassembly structure.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

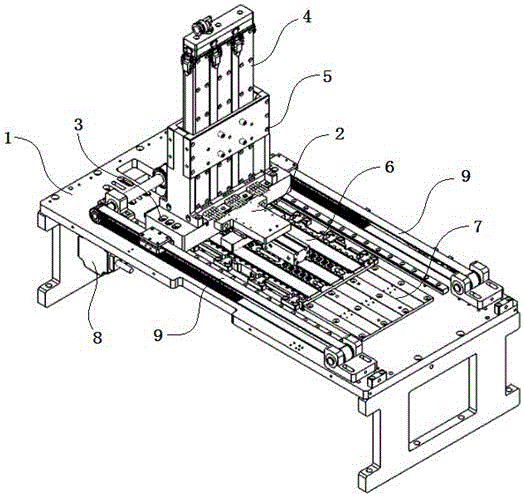

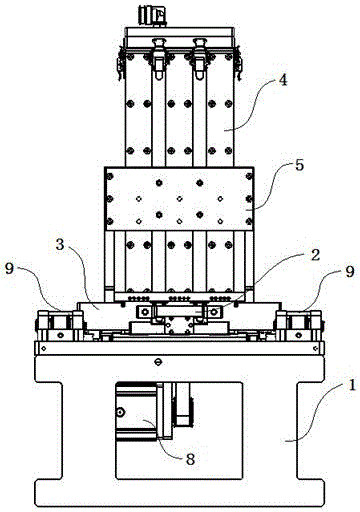

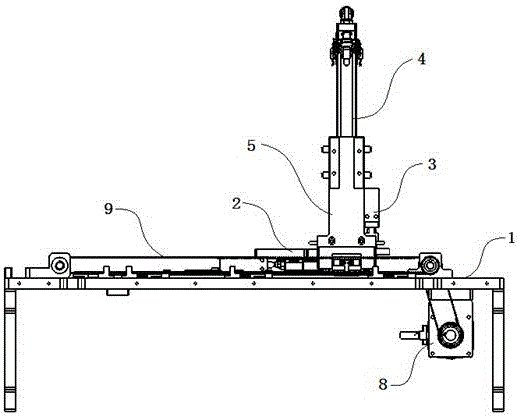

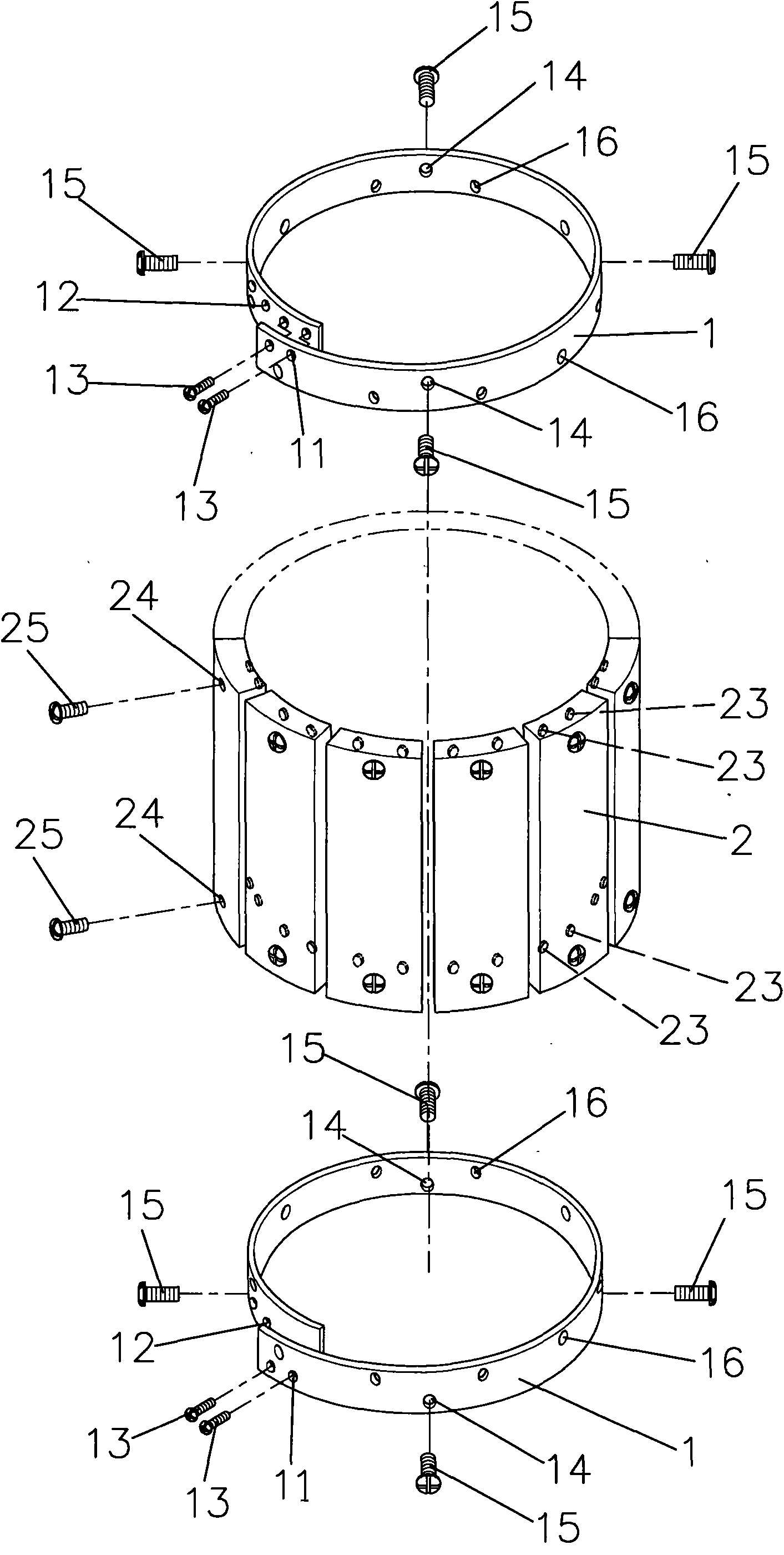

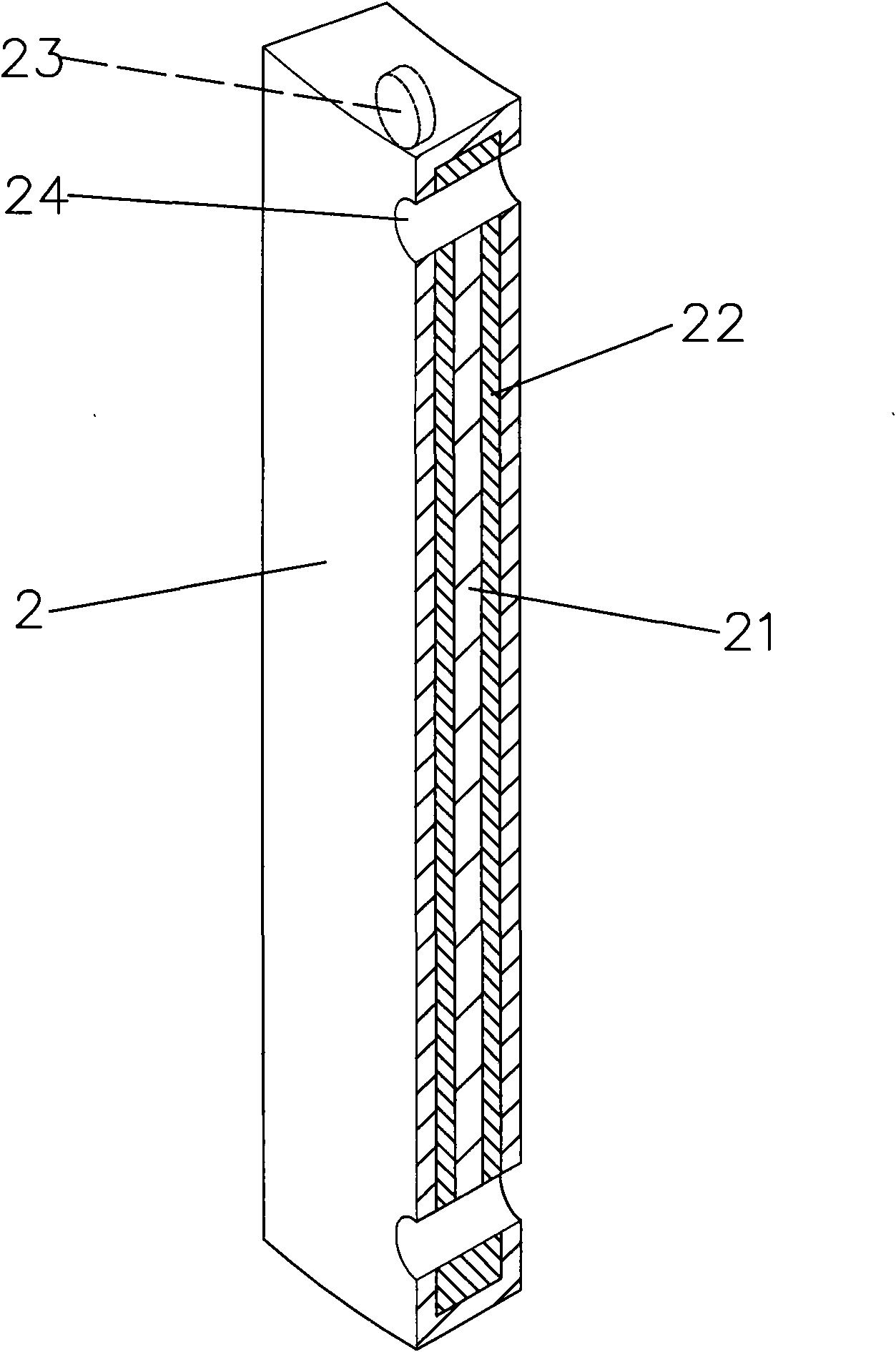

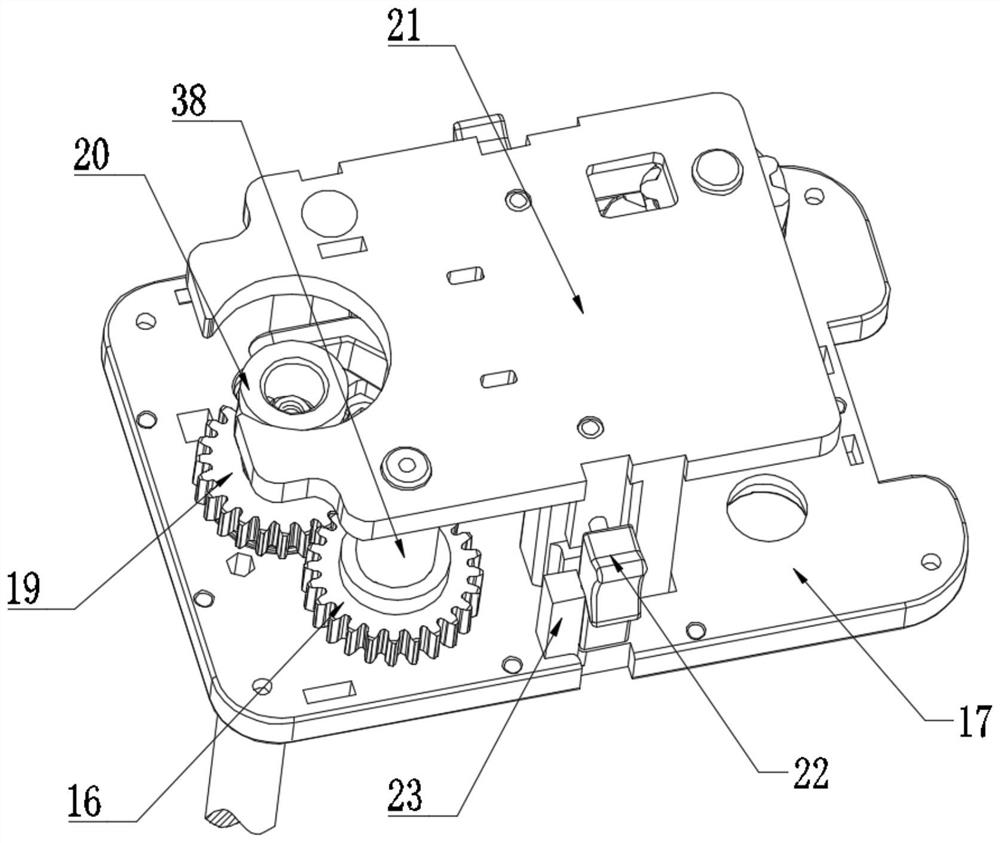

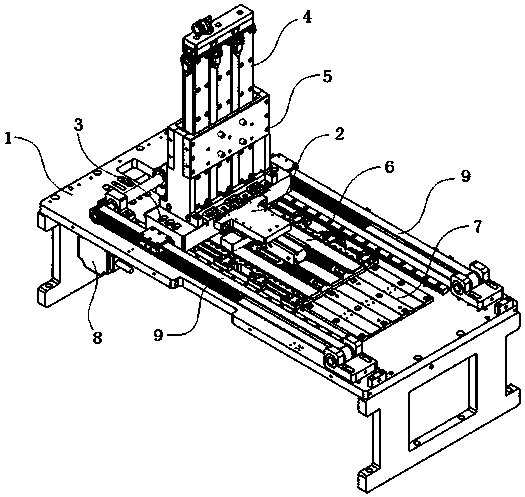

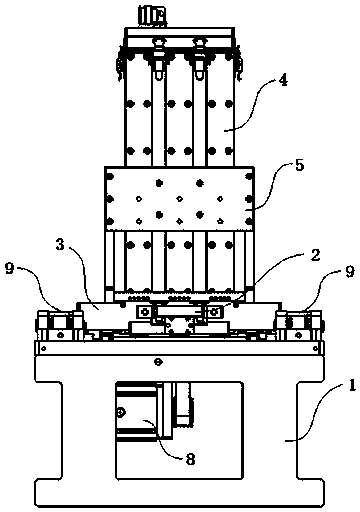

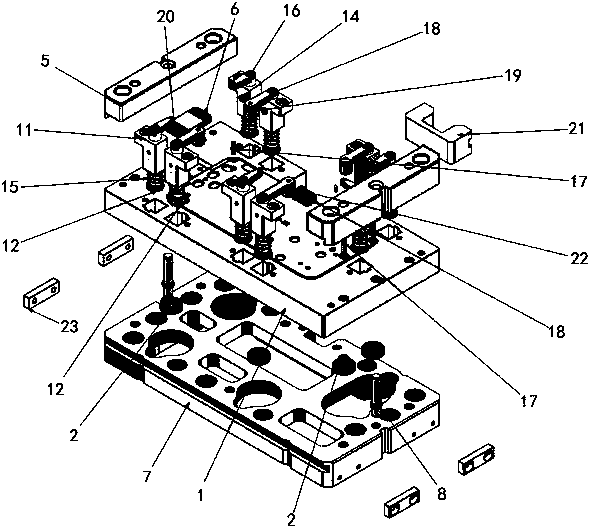

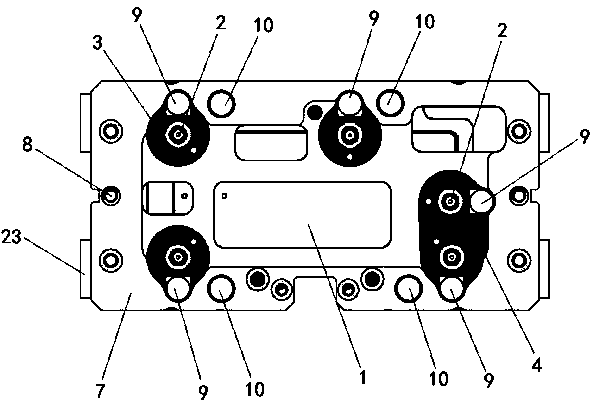

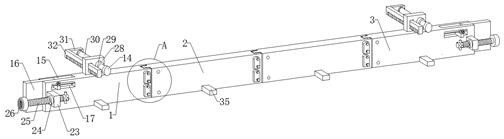

Magnet assembling mechanism

ActiveCN106041465AEasy to processEasy maintenanceMetal working apparatusProduction lineElectric machinery

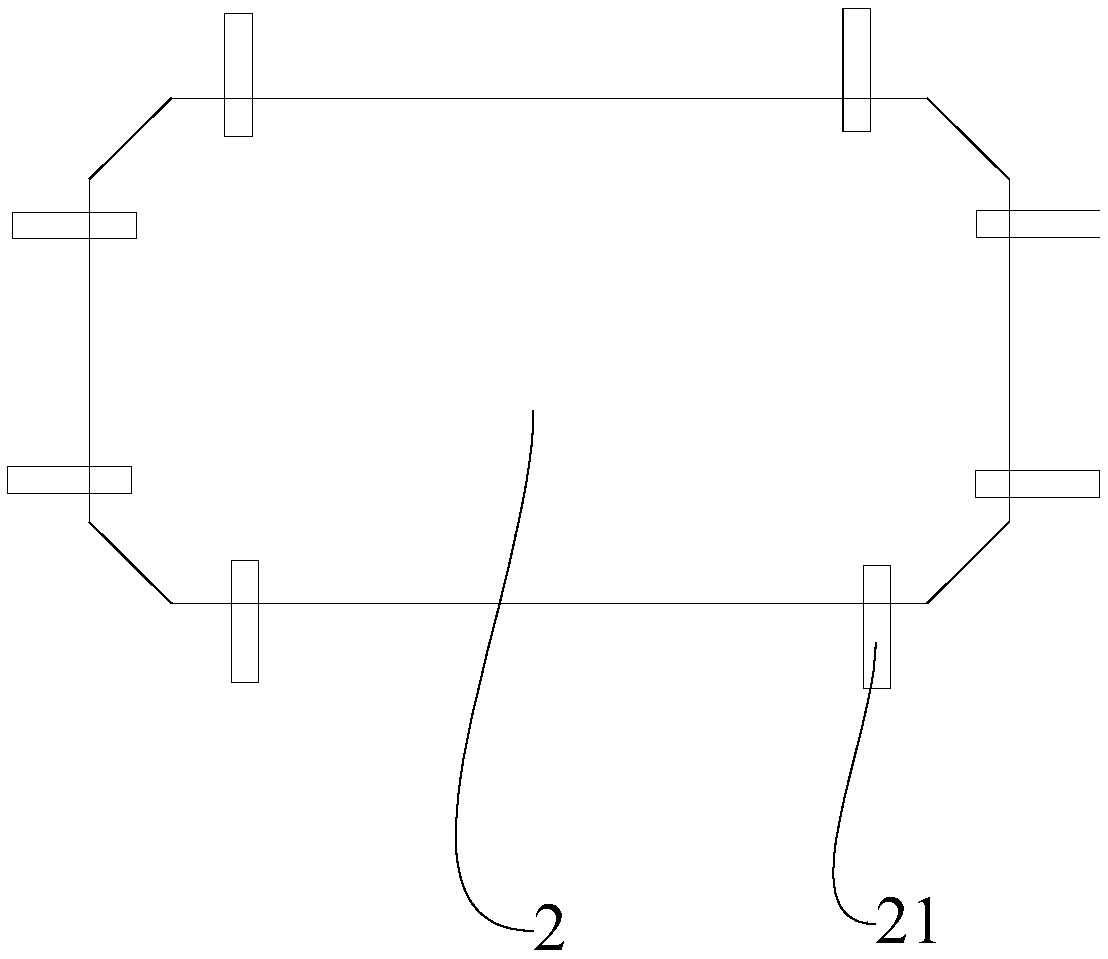

The invention discloses a magnet assembling mechanism. The magnet assembling mechanism comprises an assembling working table, a conveying mechanism, a separating mechanism, a filling mechanism, a rapid disassembling magazine, a magazine holding mechanism and a tray, wherein a carrier plate used for placing the tray is arranged in the center of the table surface of the assembling working table; the conveying mechanism comprises two conveyor belts driven by a motor, and the two conveyor belts are separately arranged on the table surface, on the left and right sides of the carrier plate, of the assembling working table; and the filling mechanism is arranged on the two conveyor belts, the separating mechanism is arranged at the front part of the filling mechanism, the magazine holding mechanism is arranged at the upper part of the filling mechanism, and the rapid disassembling magazine is perpendicularly plugged on the magazine holding mechanism. The mechanism has the advantages of being simple to machine, simple to maintain, rapid to disassemble and assemble, low in cost, high in efficiency and the like, can be widely applied to various mobile phone production lines, and has advantages over the existing structures on the market in machining, assembly and later maintenance due to novel structural design and magnet assembling mode.

Owner:苏州茂特斯自动化设备有限公司

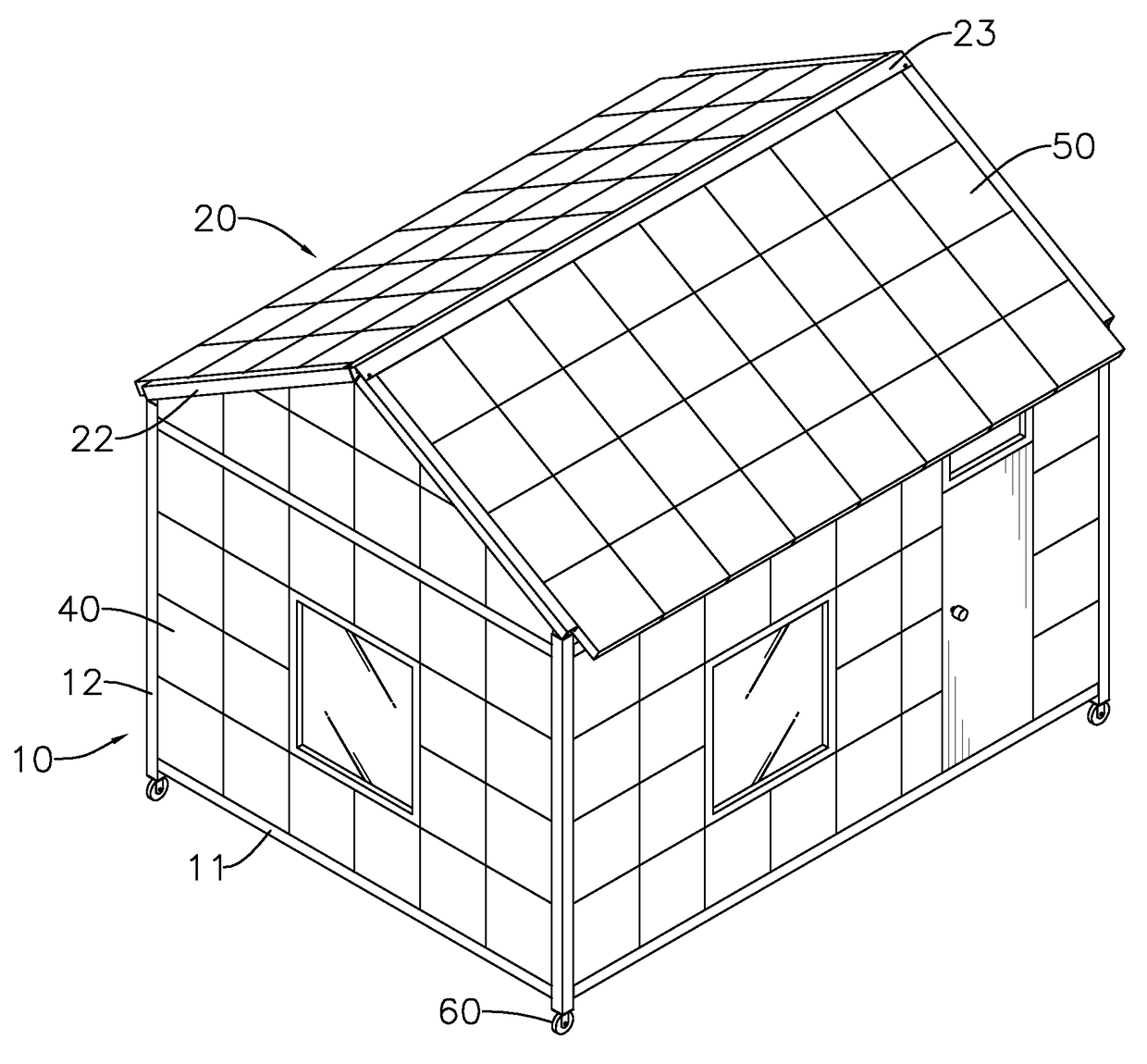

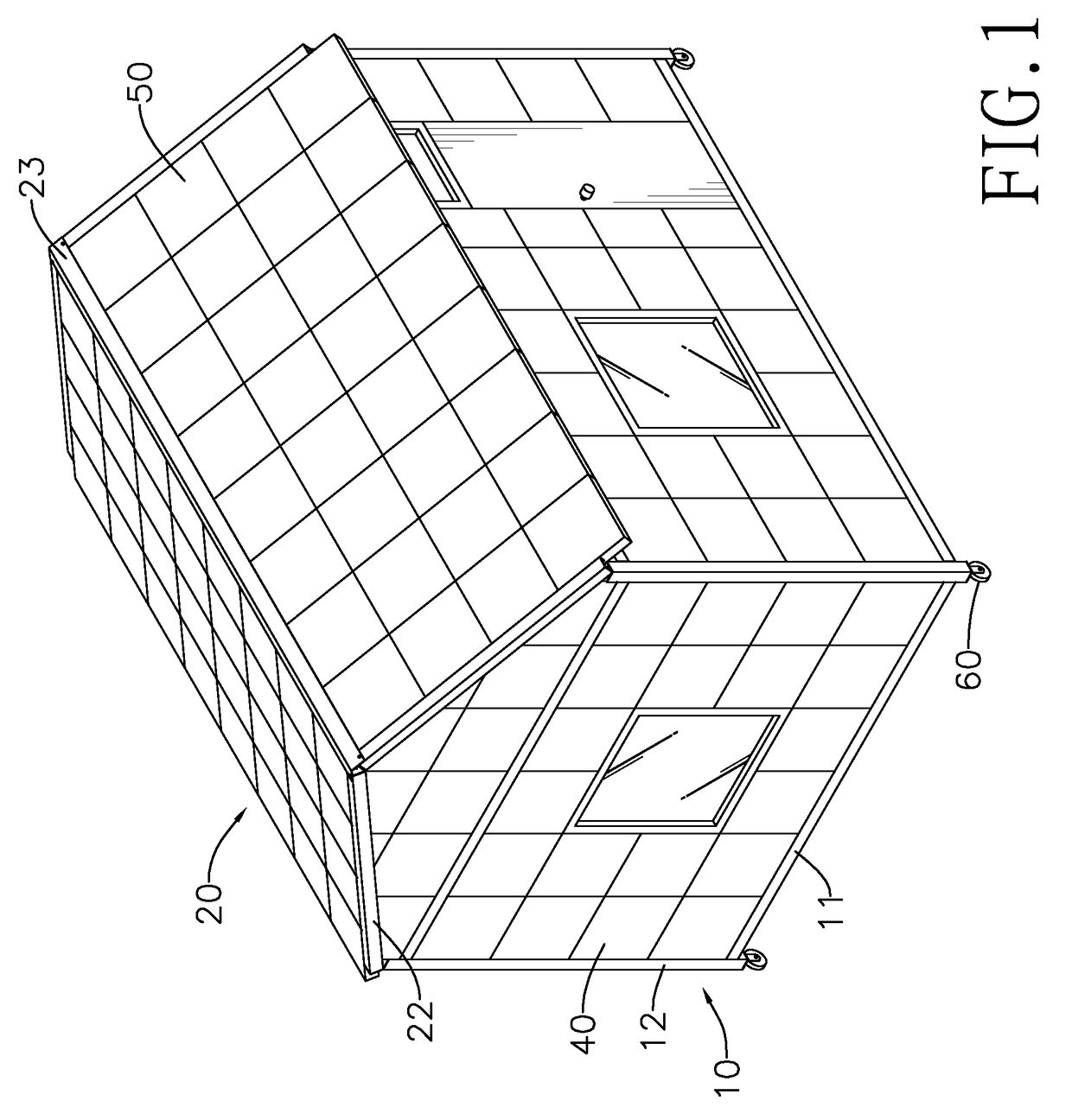

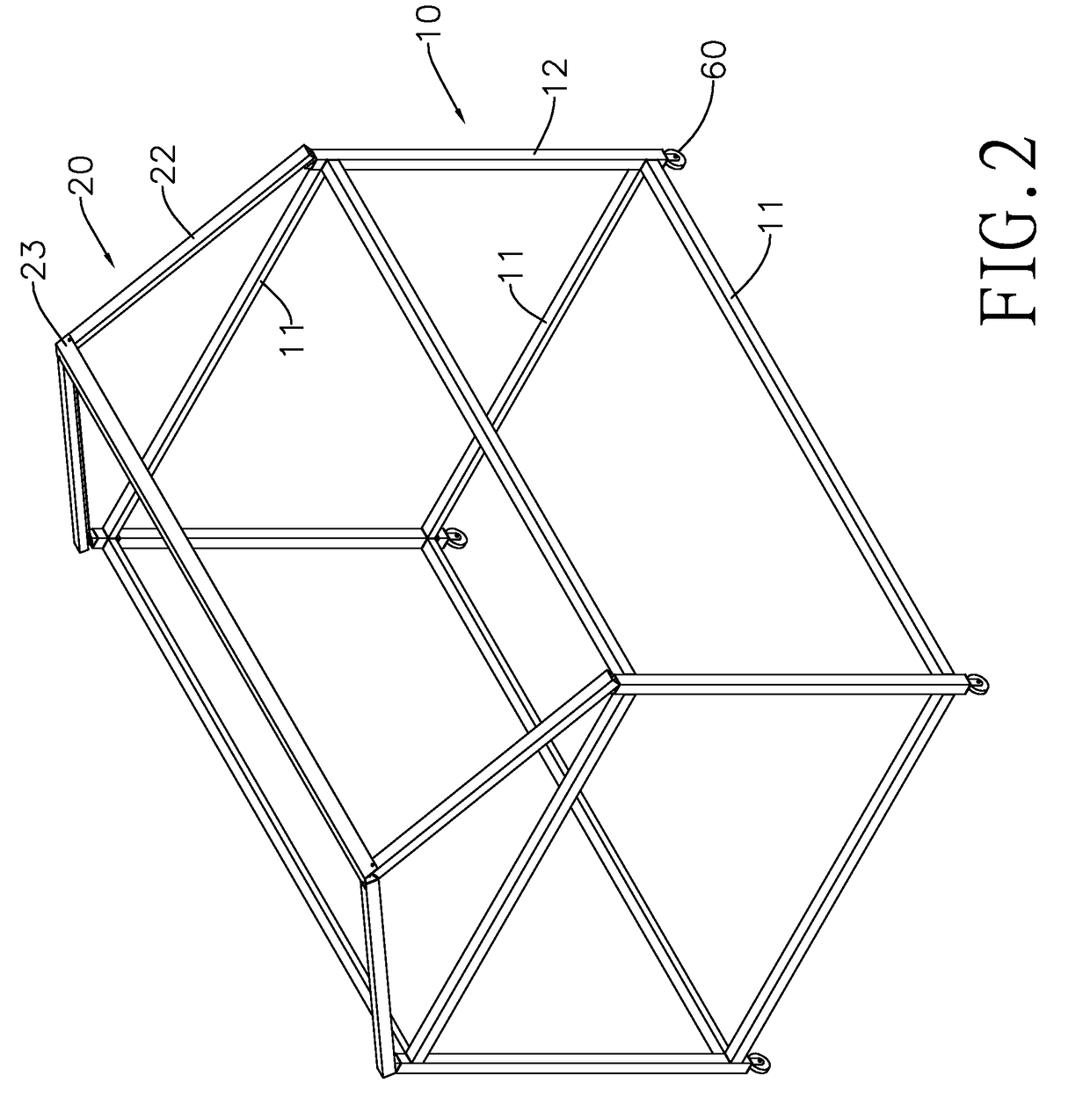

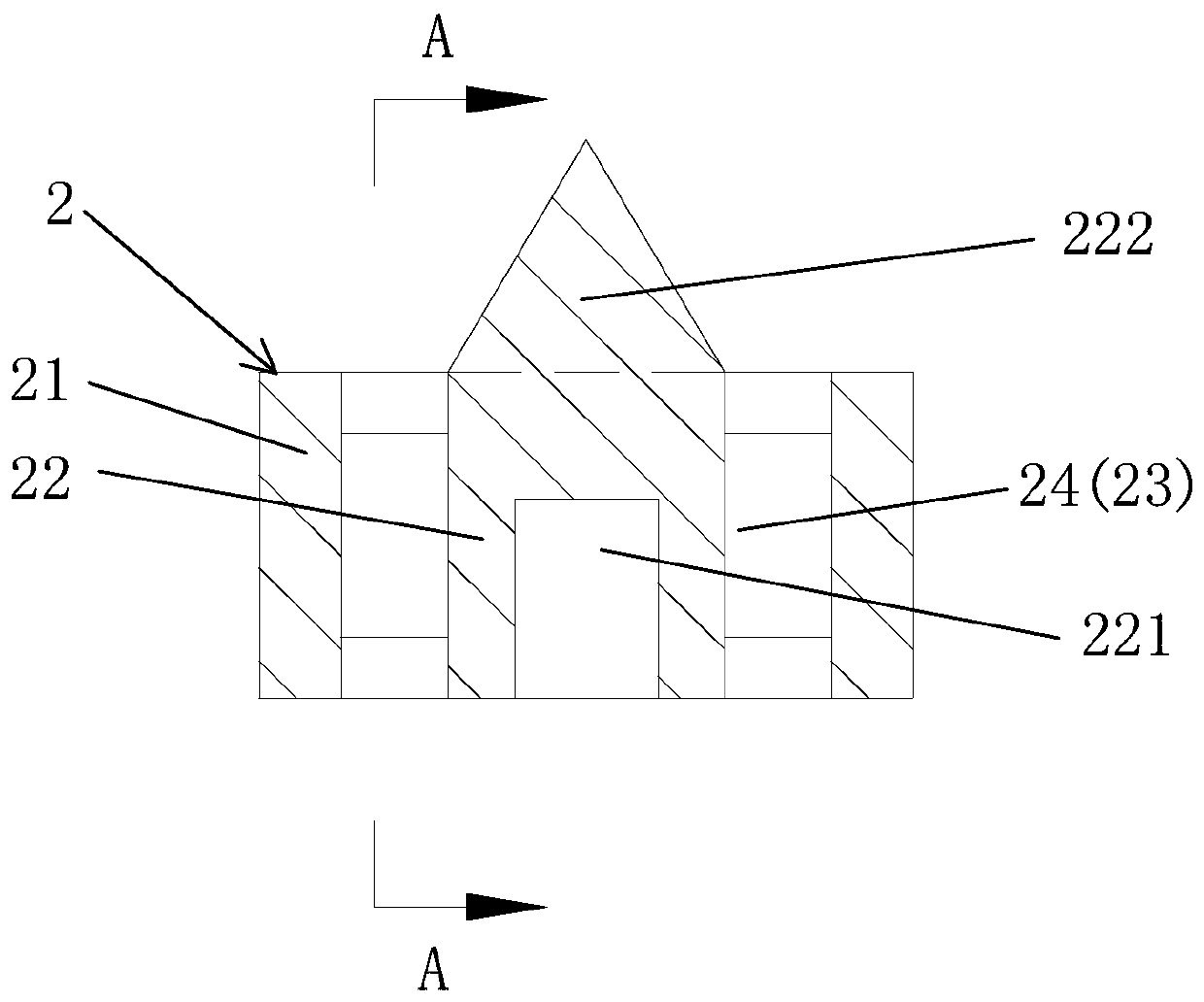

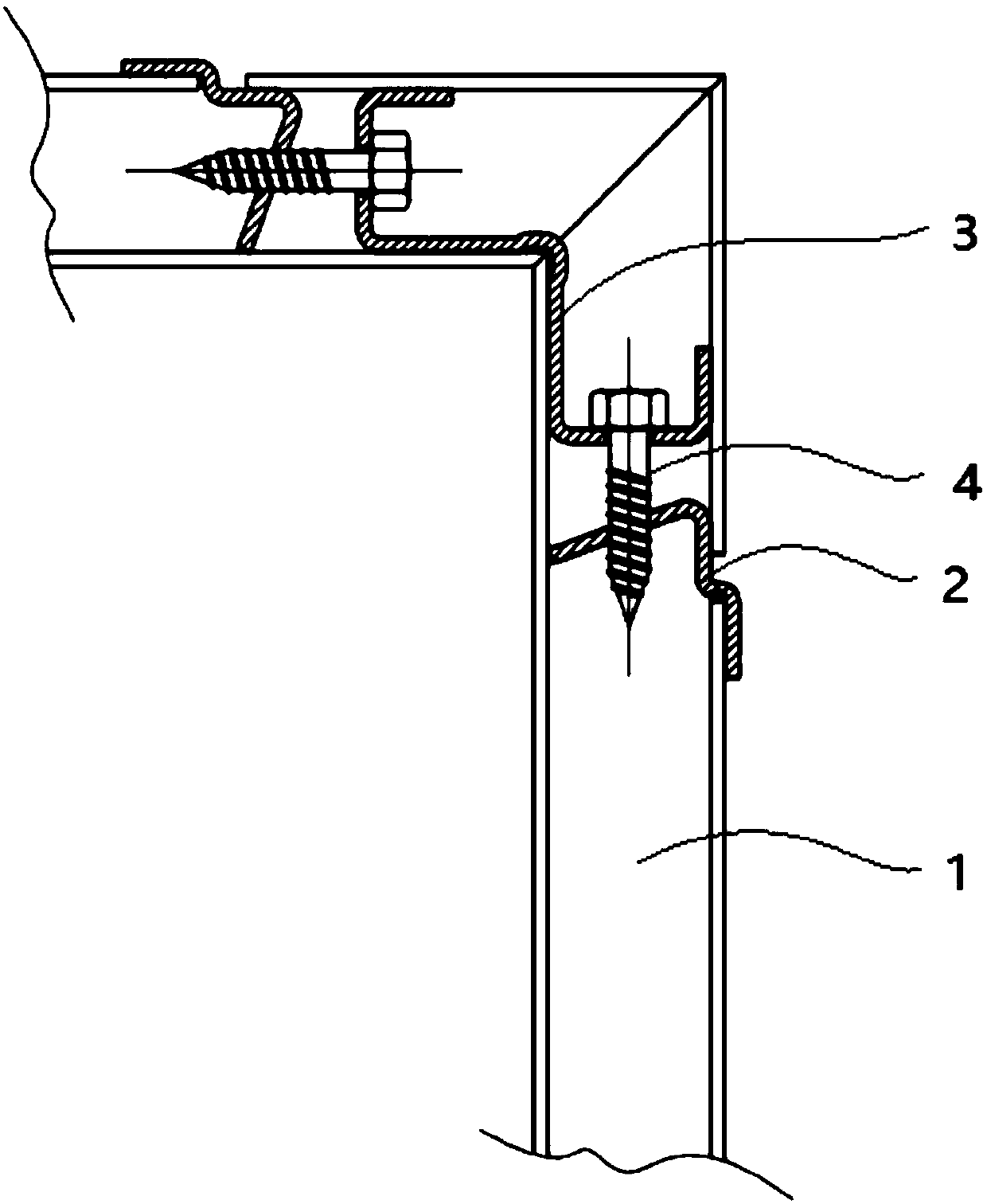

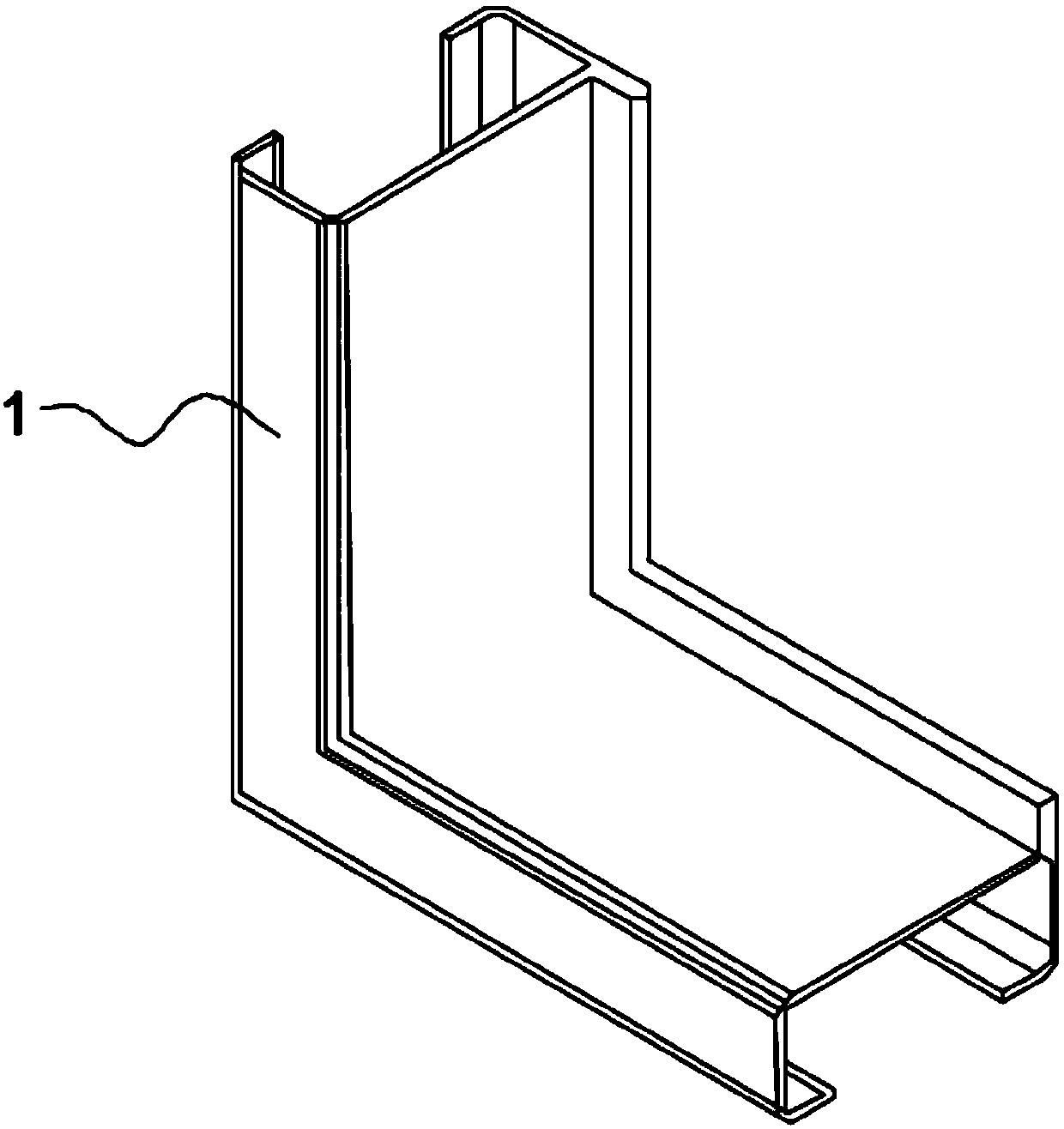

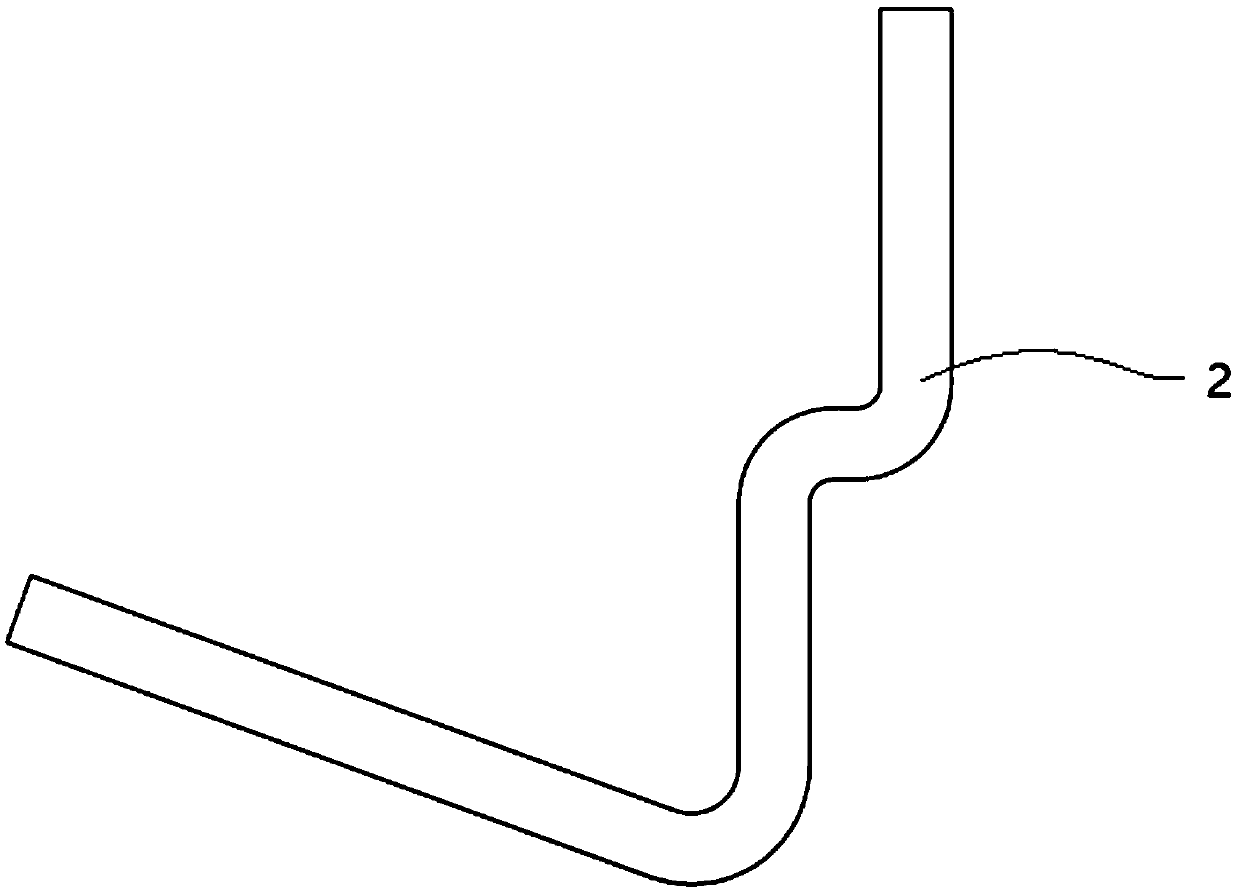

Assembled house

ActiveUS20170145708A1Easy and quick assemblyEasy and fast assemblyBuilding roofsWallsRafterMulti beam

An assembled house has a house framework, a roof framework, wall panels and a roof panel. The house framework has multiple beams, columns, and connectors. The roof framework has multiple rafters. Each one of the connectors is mounted securely in the column, and has multiple screw sleeves mounted securely in a concrete body. Thus, the beam can be connected securely to the column by screws screwed into the screw sleeve of the connector. Welding is not required for assembling the house framework on the site of the assembled house, thereby effectively accelerating the assembling. In addition, the beams and the columns are connected without welding, which eliminates the problem that the welded portions may easily rust. Furthermore, the columns, rafters, and the beams are hollow tubes, which can effectively lower the weight of the whole assembled house.

Owner:CHEN SHENG LIANG

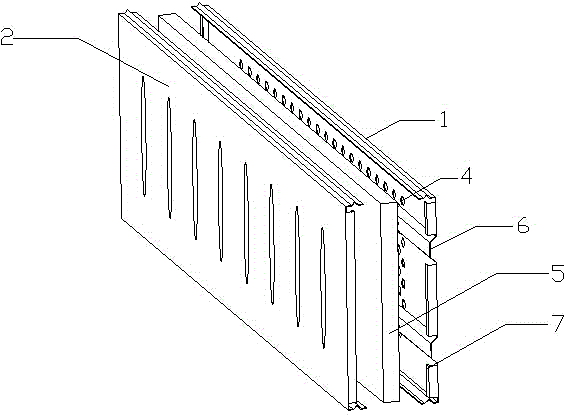

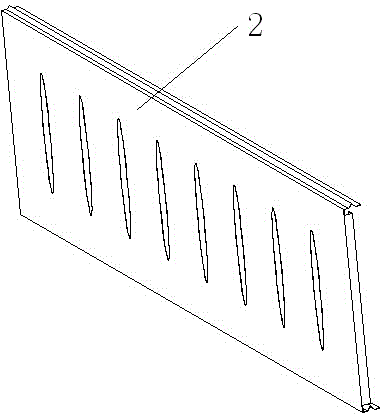

Sound barrier unit plate

InactiveCN104060554AImprove noise reductionEasy and quick assemblyNoise reduction constructionCement boardEngineering

The invention discloses a sound barrier unit plate, which belongs to the field of environment protection. The sound barrier unit plate consists of a sound absorption plate, a sound absorption material and a sound isolation plate, wherein the sound absorption material is arranged in a cavity formed between the sound absorption plate and the sound isolation plate. Sound waves enter a foamed cement plate sound absorption material through sound absorption holes formed in the sound absorption plate, a great number of tiny communicated pores are formed inside the sound absorption material, the sound waves can go deep into the material along the pores to generate friction effects with the material, and the sound energy is converted into heat energy. The sound waves passing through the foamed cement plate sound absorption material collide with the surface of a sound isolation material, and are then reflected to the foamed cement plate sound absorption material to generate secondary friction effects with the material, and the sound energy is converted into the heat energy for a second time, so the sound isolation effect is achieved.

Owner:JIANGSU XINGUANG ENVIRONMENTAL PROTECTION ENG

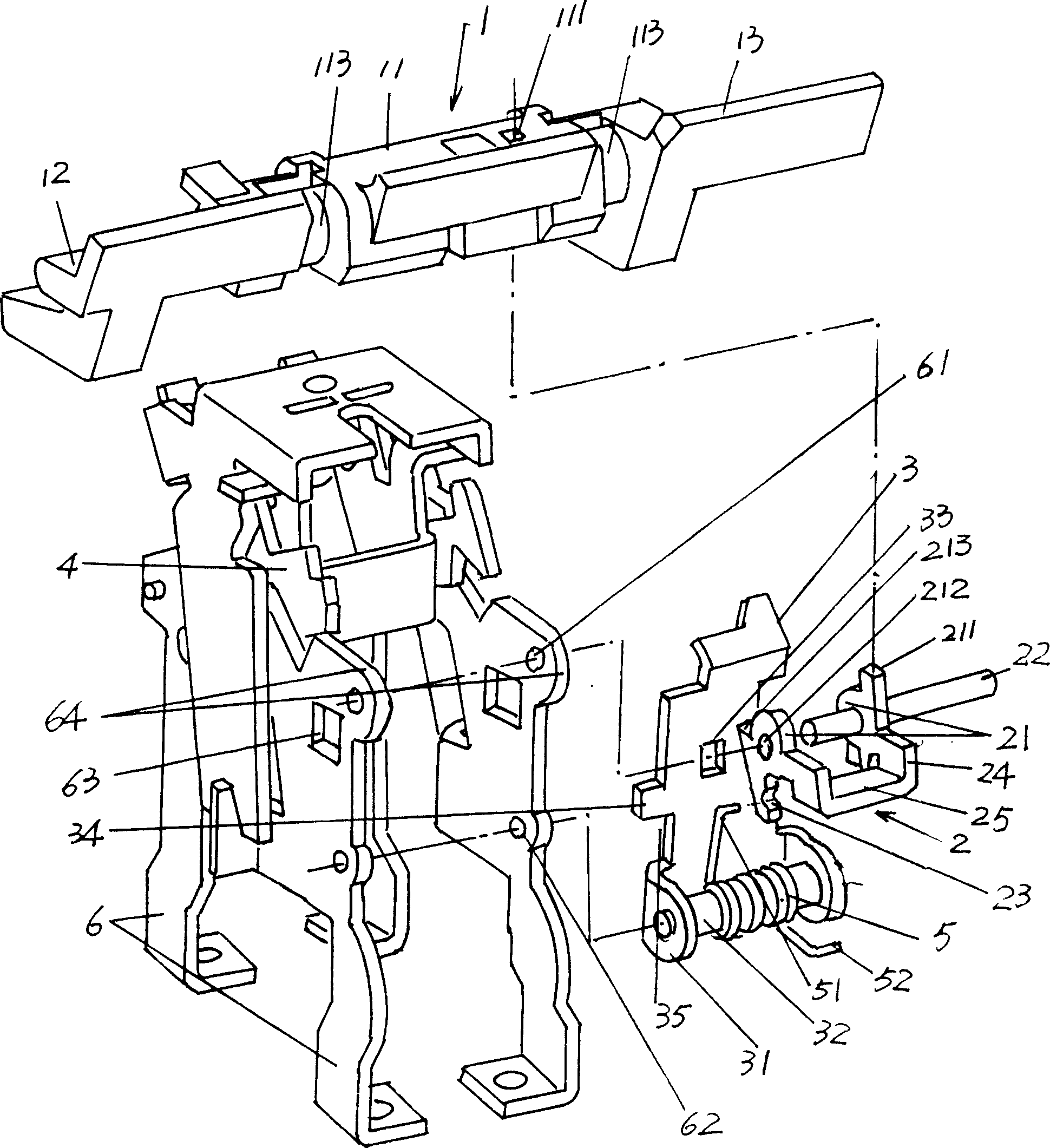

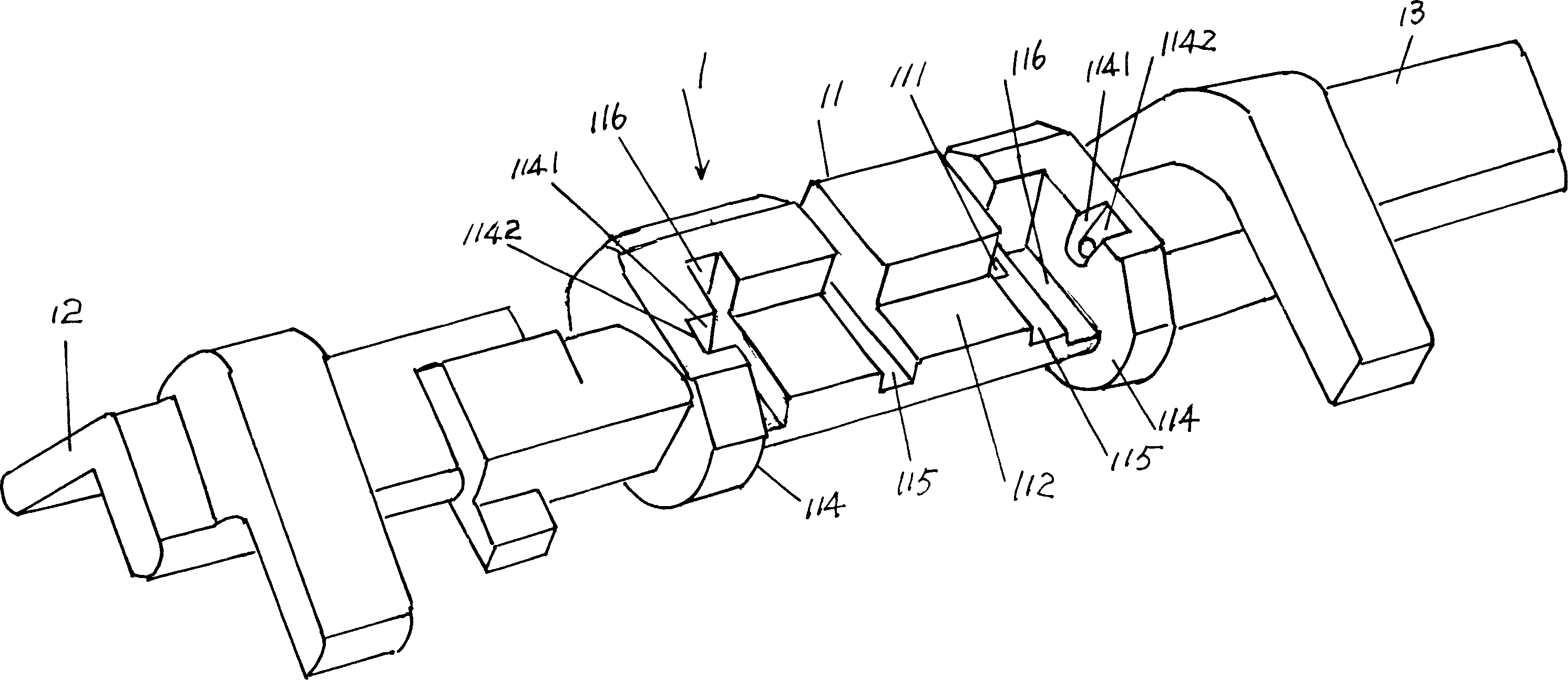

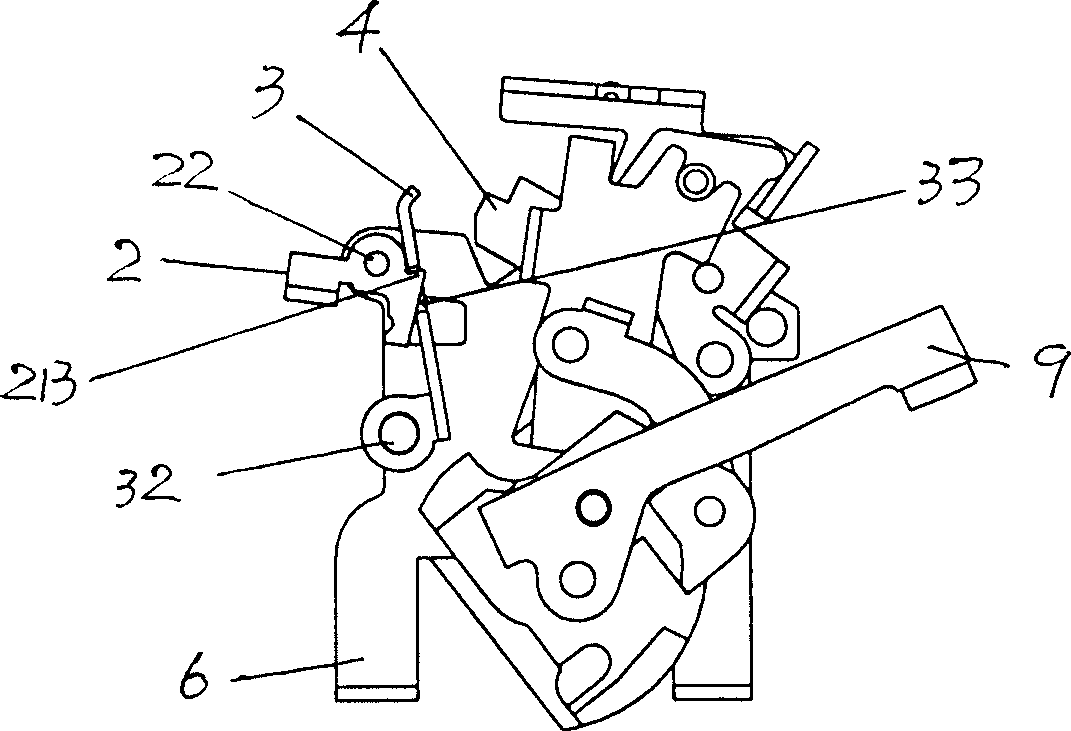

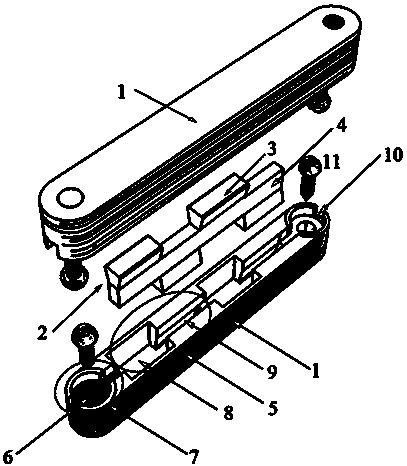

Tripping device for breaker operation mechanism

ActiveCN1901125AEasy and quick assemblyReduce fastenersProtective switch operating/release mechanismsFastenerEngineering

This invention relates to a trip device for a breaker operation unit including a first and a second lock buttons having a pair of first and second pivoted flanges, a hop button, a spring and a traction rod characterizing that tenons are set on any pivoted flange in the pair of the first flanges of the first lock button and tenon holes are set on the middle section of the traction rod opposite to the tenons, grooves are set axially at the back of the middle section of the traction rod and swivel grooves are set on the opposite internal walls of the back of the middle section and the axis of the swivel groove and that of the groove are on a same line.

Owner:CHANGSHU SWITCHGEAR MFG CO LTD (FORMER CHANGSHU SWITCHGEAR PLANT)

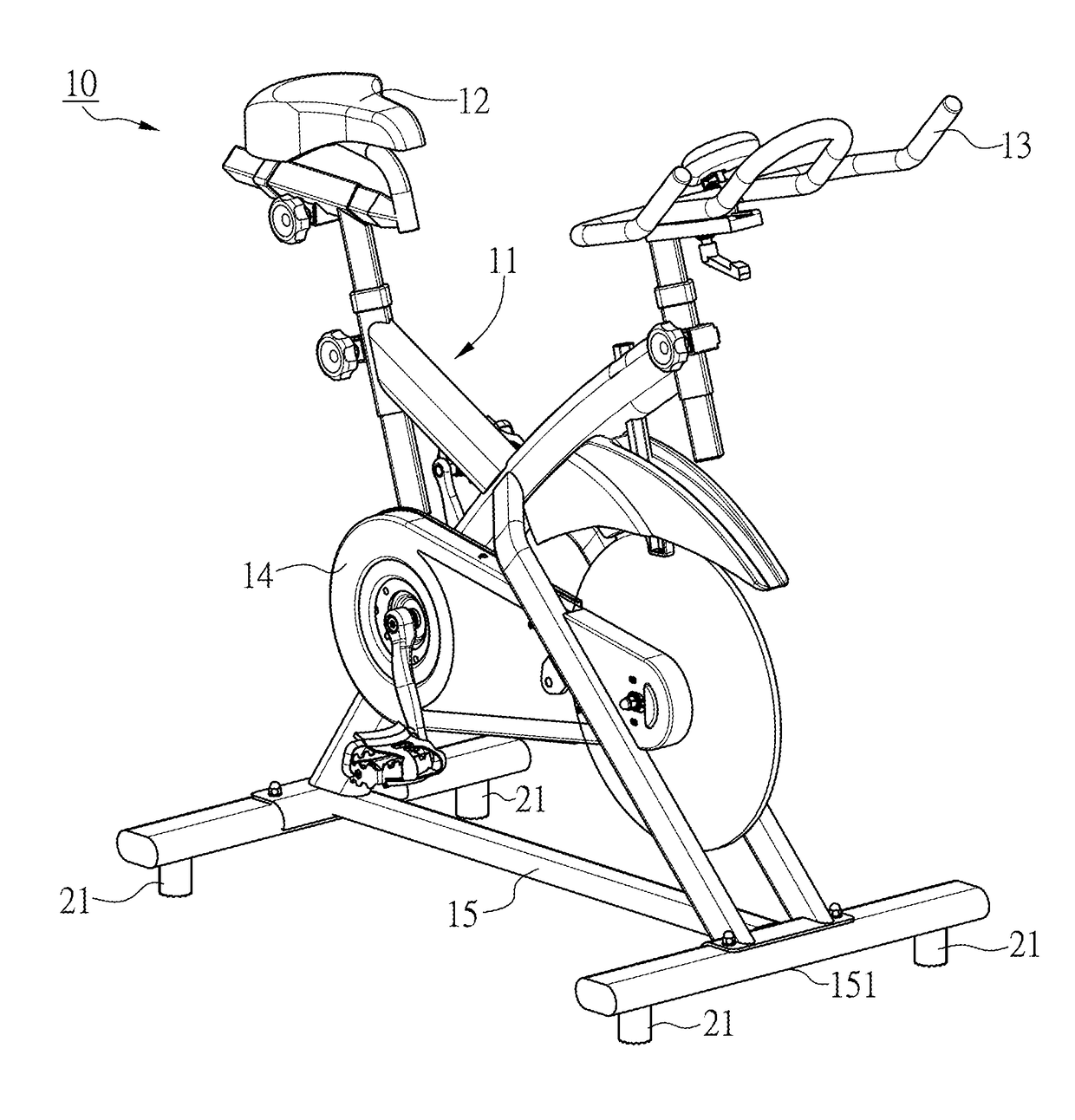

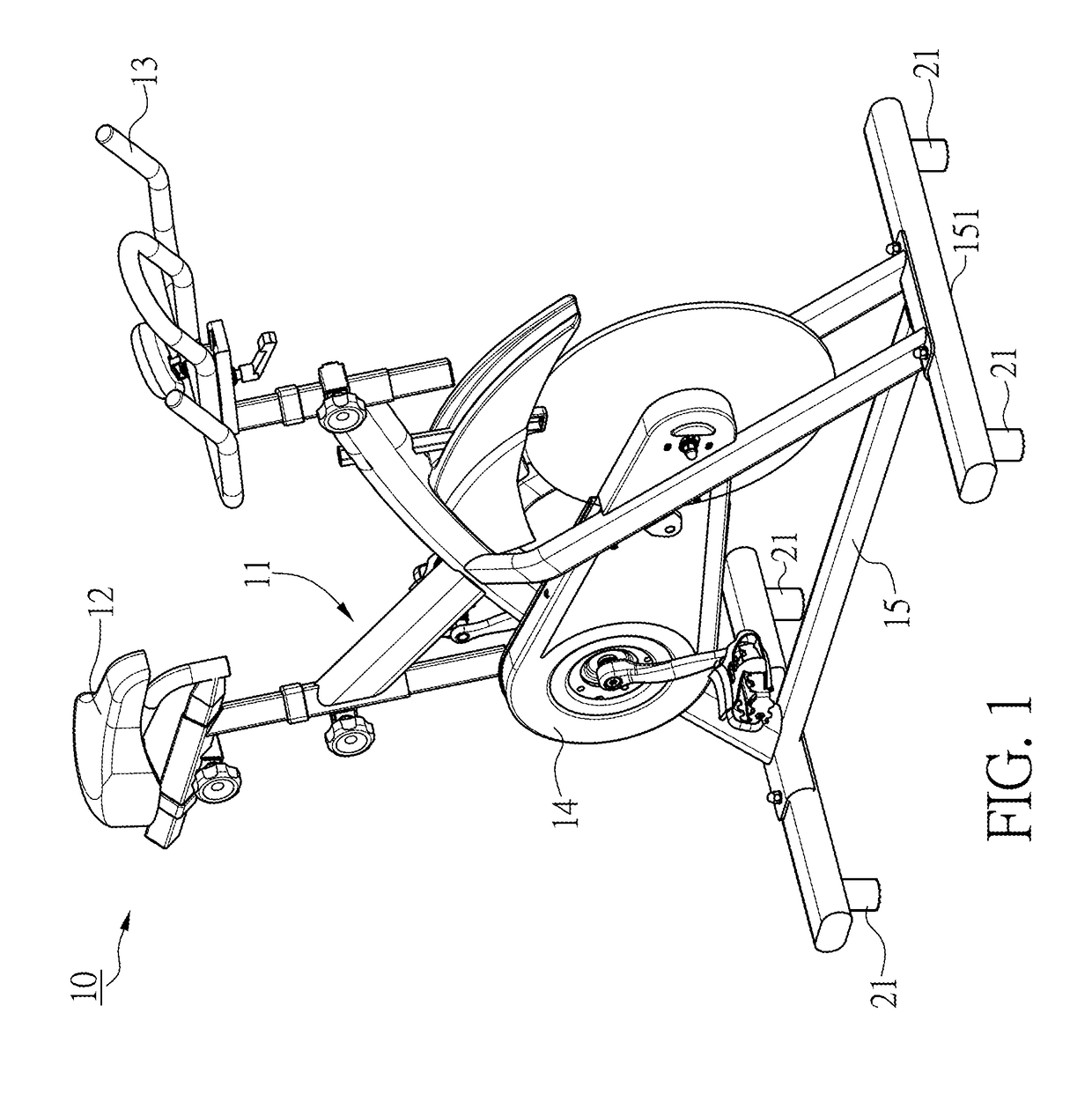

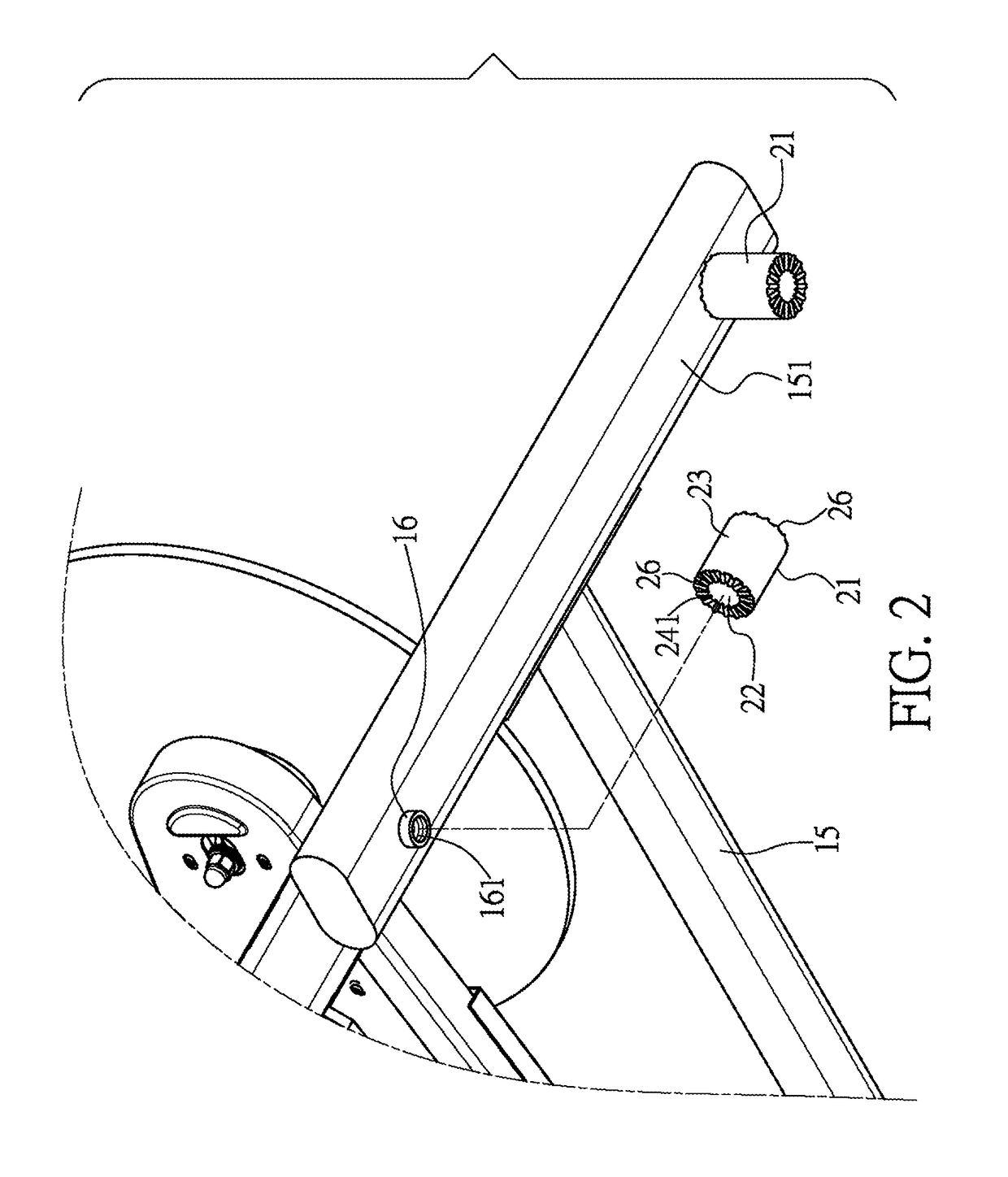

Stationary bike

InactiveUS20170216662A1Easy and quick assemblySaving additional conversion costMovement coordination devicesCardiovascular exercising devicesInterior spaceEngineering

Owner:BH ASIA HONG KONG HLDG CO LTD

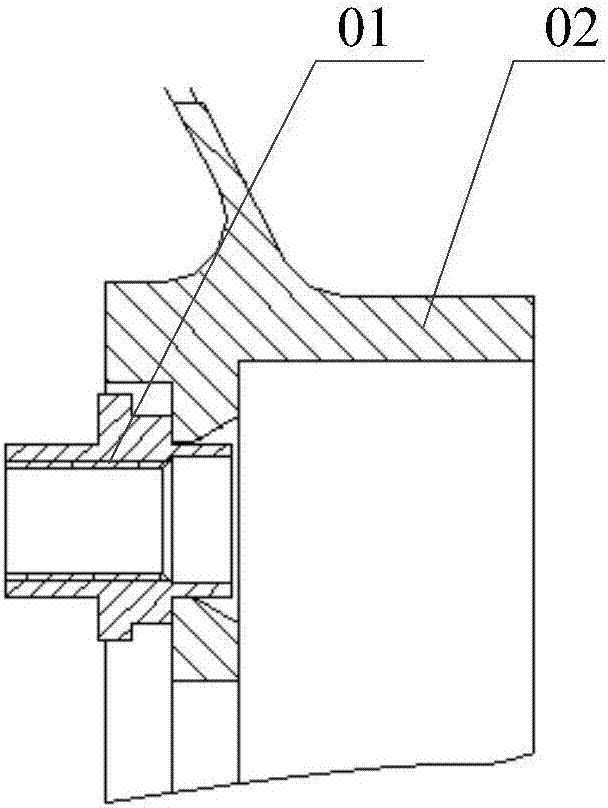

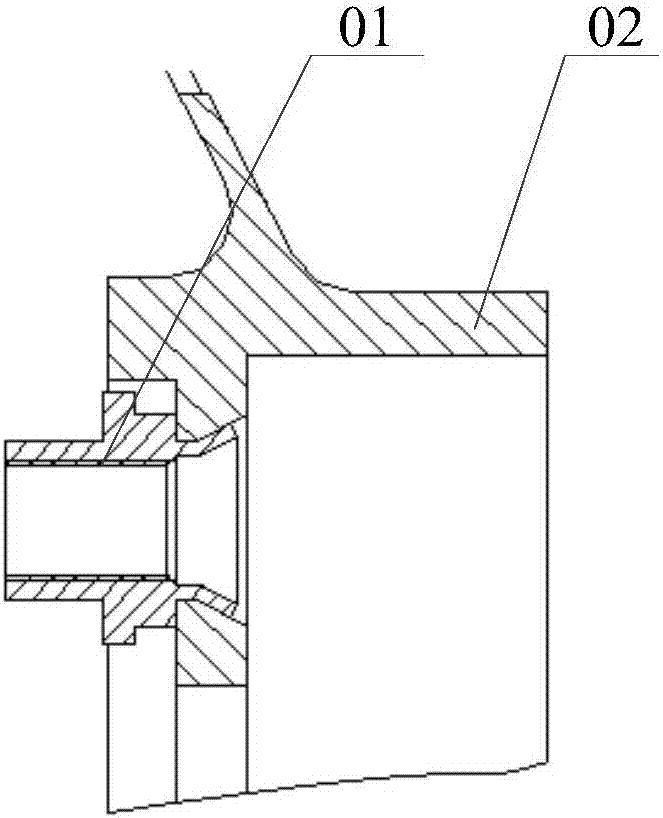

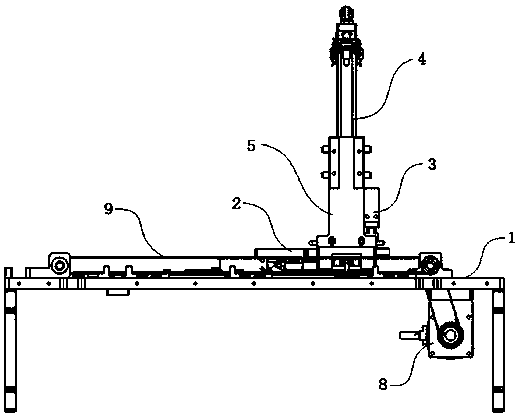

Assembly device for thin-wall part assembly self-locking nut

The invention discloses an assembly device for a thin-wall part assembly self-locking nut. The assembly device comprises a pin assembly fixture for placing a punch and a self-locking nut, and an adjustable press; and the adjustable press comprises a connecting part for detachably connecting with the pin assembly fixture, and a control part for prepressing the self-locking nut through pressing the punch after clamping of the self-locking nut and riveting the self-locking nut through pressing the punch after prepressing. Through two-gear setting of prepressing and riveting, the assembly device effectively prevents stressed deformation of combined edges of the self-locking nut, and reduces the scrap rate of the self-locking nut and a thin-wall part; the adjustable press is adopted to improve the automation degree of installing the self-locking nut on the thin-wall part; the assembly operation is simple, convenient, fast and low in labor intensity; the once assembly pass percent can reach 100%; the rework is not needed; and the assembly efficiency and quality are greatly improved.

Owner:HUNAN SOUTH GENERAL AVIATION ENGINE CO LTD

Motorcycle turn detection method and warning method thereof

Owner:CHONGQING BAOHUA MOTORCYCLE

Combined hot pan energy-saving device

InactiveCN101664279AEmission reductionReduce consumptionCooking utensils shields/jacketsMetallic enclosureHeating time

Owner:方赞堂

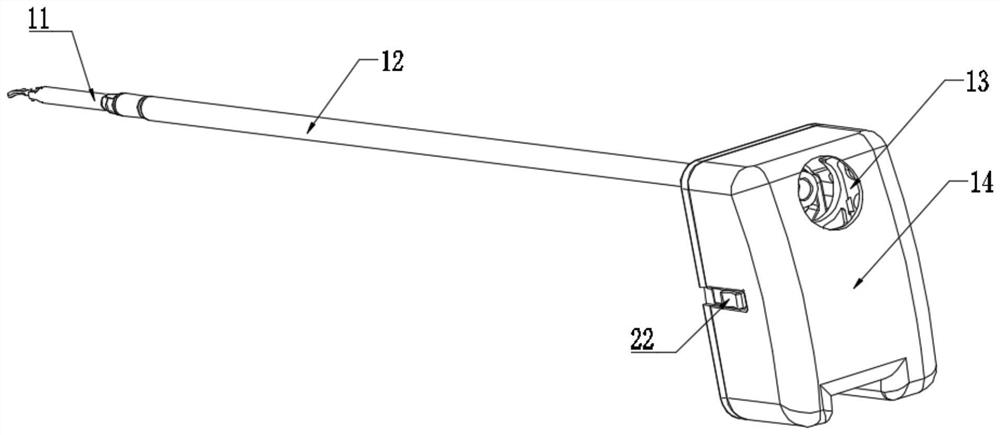

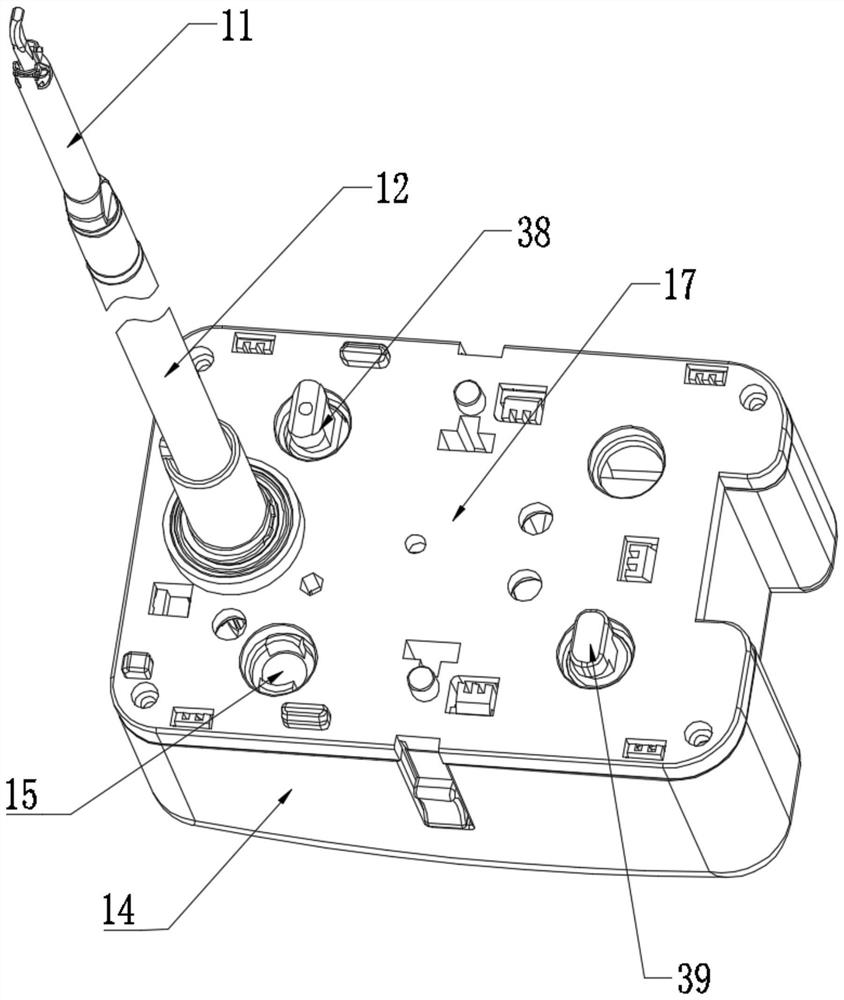

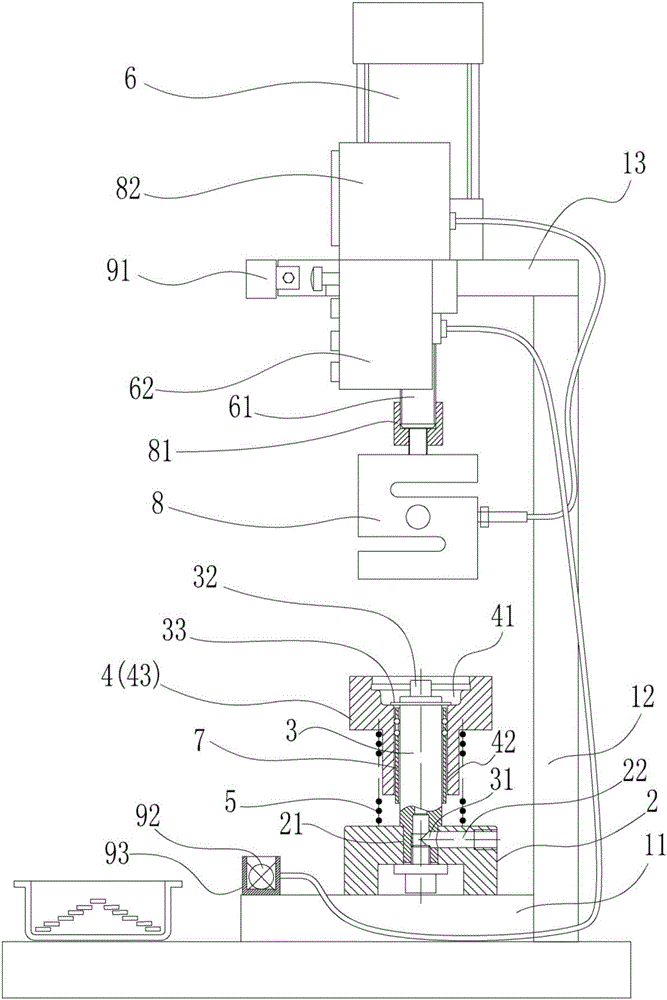

Surgical operating instrument driving mechanism, ultrasonic knife and minimally invasive surgery robot

PendingCN114469268ASmall sizeEasy and quick assemblyEndoscopic cutting instrumentsSurgical robotsSurgical instrumentInvasive surgery

The invention discloses a surgical operating instrument driving mechanism, an ultrasonic knife and a minimally invasive surgery robot, the surgical operating instrument driving mechanism comprises a bottom plate, and an adapter used for being coupled with a surgical instrument and a rotating mechanism used for autorotation of the adapter are movably arranged on the bottom plate. The rotation of the ultrasonic knife is realized by driving the adapter coupled with the surgical instrument to rotate, the lifting of the adapter is realized by the broken-line-shaped lever mechanism to drive the opening and closing of the ultrasonic knife, and the input end and the output end of the lever mechanism are close to the moment arm length of a rotating node, so that the strokes of the input end and the output end of a lever are close to each other; the size of the whole driving mechanism is greatly reduced, the broken line type structure facilitates the space design of the bottom plate, meanwhile, the output end of the lever structure and the adapter adopt a coupling mode that the annular groove is matched with the sliding piece, so that the adapter can be integrally machined, the assembly of the adapter and the lever is simpler and more convenient, and the whole manufacturing cost is reduced.

Owner:常州唯精医疗机器人有限公司

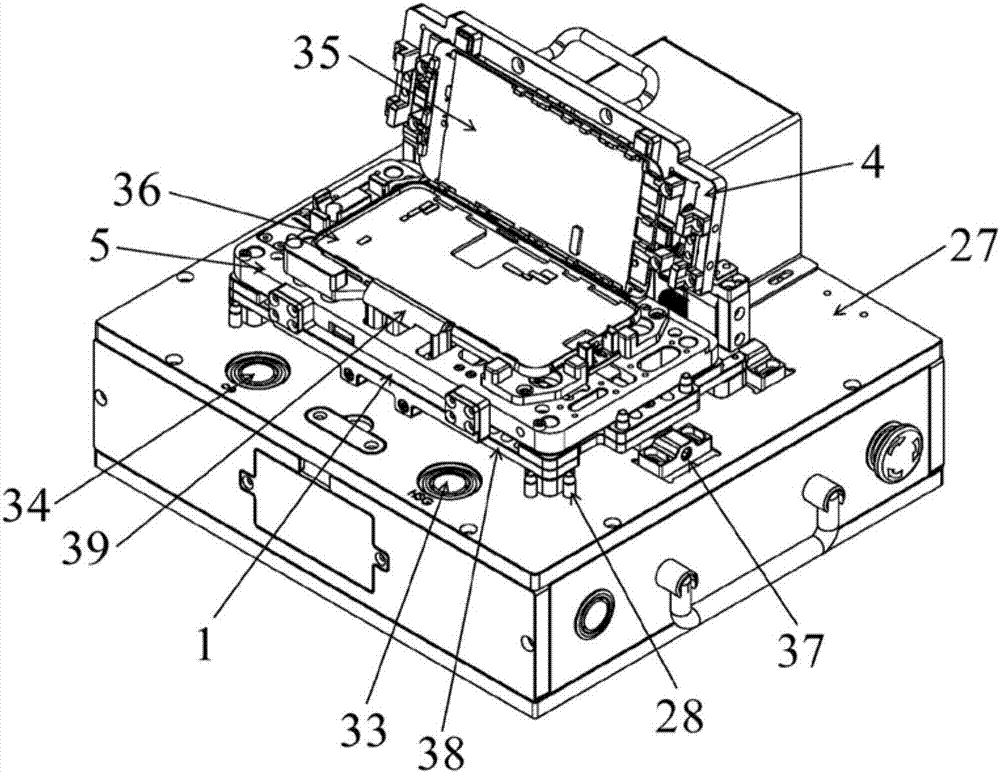

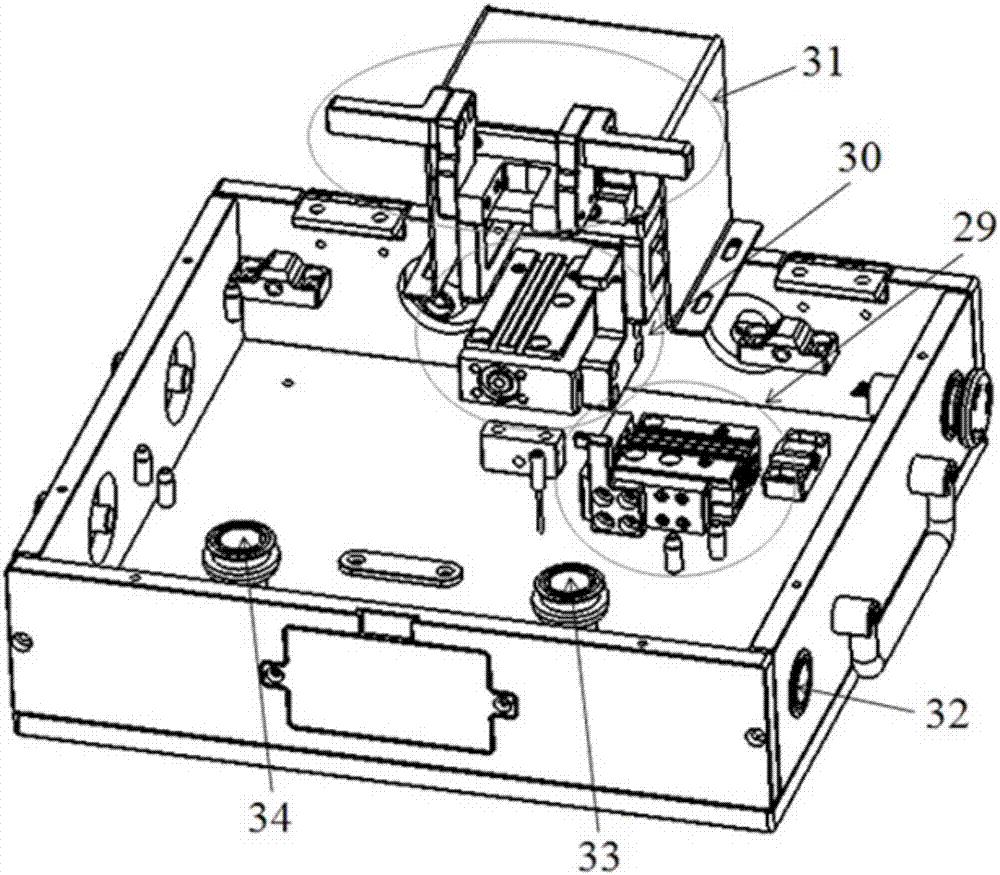

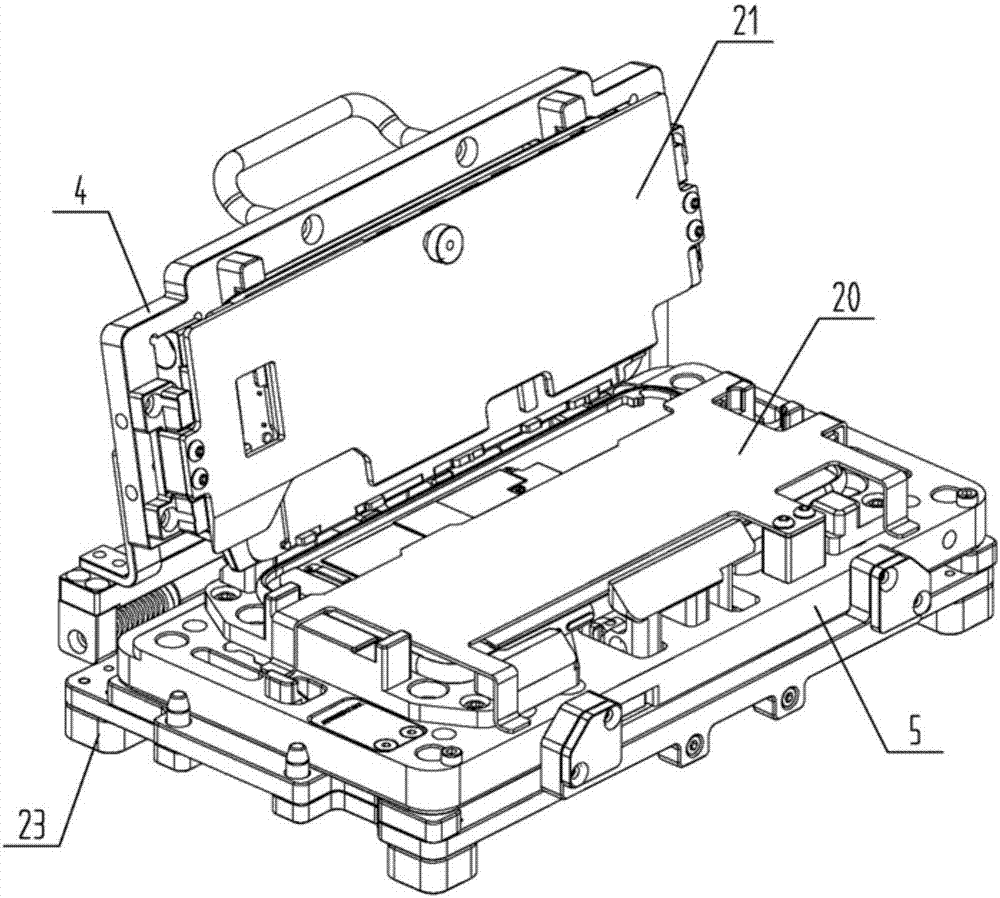

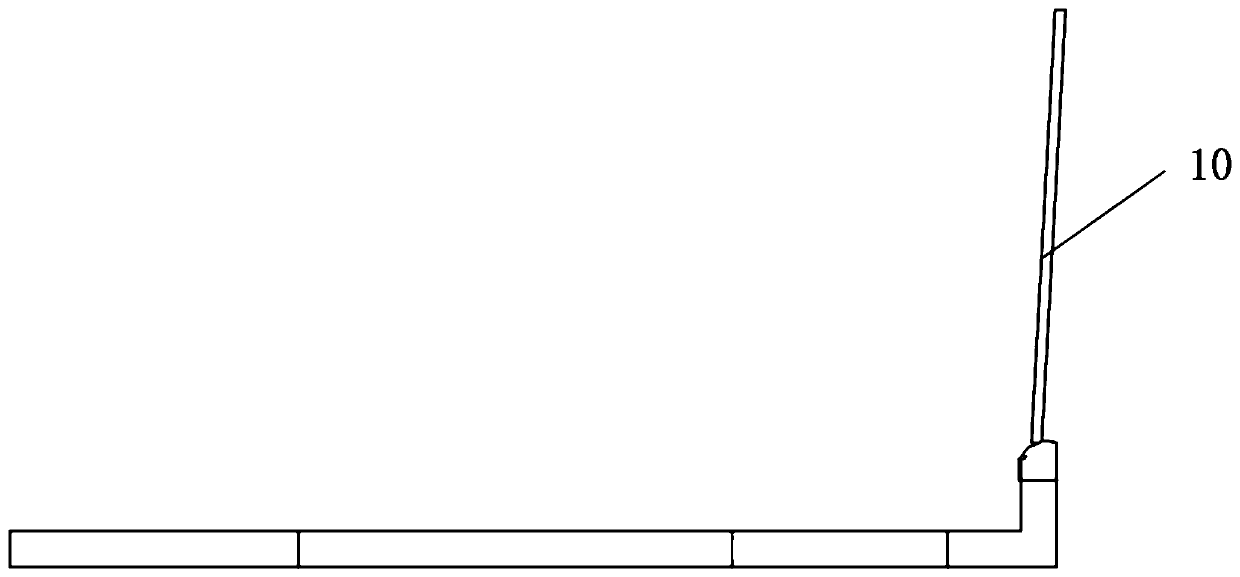

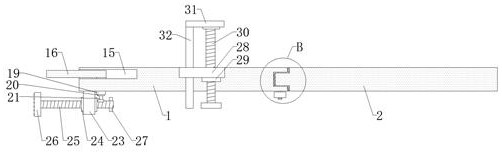

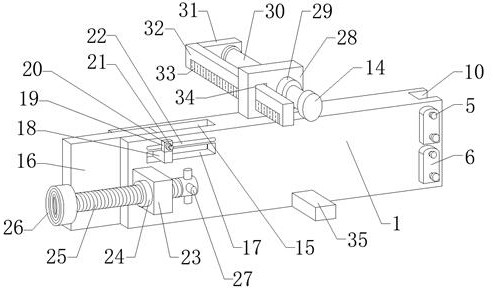

Transfer carrier assembly jig

The invention discloses a transfer carrier assembly jig which comprises an electrical cabinet and a transfer carrier detachably mounted on the electrical cabinet. The transfer carrier comprises a bottom plate, a shell module, a display screen module, a shell module fixing device, a display screen fixing device and a shell fixing device. The bottom plate is detachably mounted on the electrical cabinet. The display screen module is arranged on one side of the bottom plate and inclines relative to the bottom plate. The shell module fixing device can fix the shell module to the bottom plate. A display screen can be fixed to the display screen module through the display screen fixing device. A shell can be fixed to the shell module through the shell fixing device. The transfer carrier assembly jig has the beneficial effects of being capable of assembling the display screen and the shell easily and fast, simple in structure and easy and convenient to operate.

Owner:昆山铭世特精密机械有限公司

A magnet assembly mechanism

ActiveCN106041465BEasy to processEasy maintenanceMetal working apparatusProduction lineElectric machinery

The invention discloses a magnet assembling mechanism. The magnet assembling mechanism comprises an assembling working table, a conveying mechanism, a separating mechanism, a filling mechanism, a rapid disassembling magazine, a magazine holding mechanism and a tray, wherein a carrier plate used for placing the tray is arranged in the center of the table surface of the assembling working table; the conveying mechanism comprises two conveyor belts driven by a motor, and the two conveyor belts are separately arranged on the table surface, on the left and right sides of the carrier plate, of the assembling working table; and the filling mechanism is arranged on the two conveyor belts, the separating mechanism is arranged at the front part of the filling mechanism, the magazine holding mechanism is arranged at the upper part of the filling mechanism, and the rapid disassembling magazine is perpendicularly plugged on the magazine holding mechanism. The mechanism has the advantages of being simple to machine, simple to maintain, rapid to disassemble and assemble, low in cost, high in efficiency and the like, can be widely applied to various mobile phone production lines, and has advantages over the existing structures on the market in machining, assembly and later maintenance due to novel structural design and magnet assembling mode.

Owner:苏州茂特斯自动化设备有限公司

Motor bearing press mounting equipment

ActiveCN106712398AEasy to assembleEasy and quick assemblyManufacturing dynamo-electric machinesEngineeringPressure sensor

The invention provides motor bearing press mounting equipment comprising the following units: a n-type support; a fixed seat fixed on the bottom plate of the support; a bearing pillar arranged above the fixed seat, wherein a boss structure is arranged on the top of the bearing pillar; an end cover sleeve capable of freely sliding up and down outside the bearing pillar, wherein a reset spring is sleeved on the lower section outside the end cover sleeve; a pressure mechanism arranged on the top plate, wherein the bottom of the pressure mechanism is connected with a vertical downward pressure rod; a control mechanism arranged on the top plate and connected with the pressure mechanism; a pressure sensor arranged on the bottom of the pressure rod and connected with a load displayer mounted on the top plate. The motor bearing press mounting equipment is simple and fast in operation, can effectively improve assembling efficiency, and the fitting tightness level between the motor bearing and the motor end cover can be determined according to the pressure, thus picking out unqualified products, and ensuring product quality.

Owner:CHONGQING AIHUA ELECTRICAL

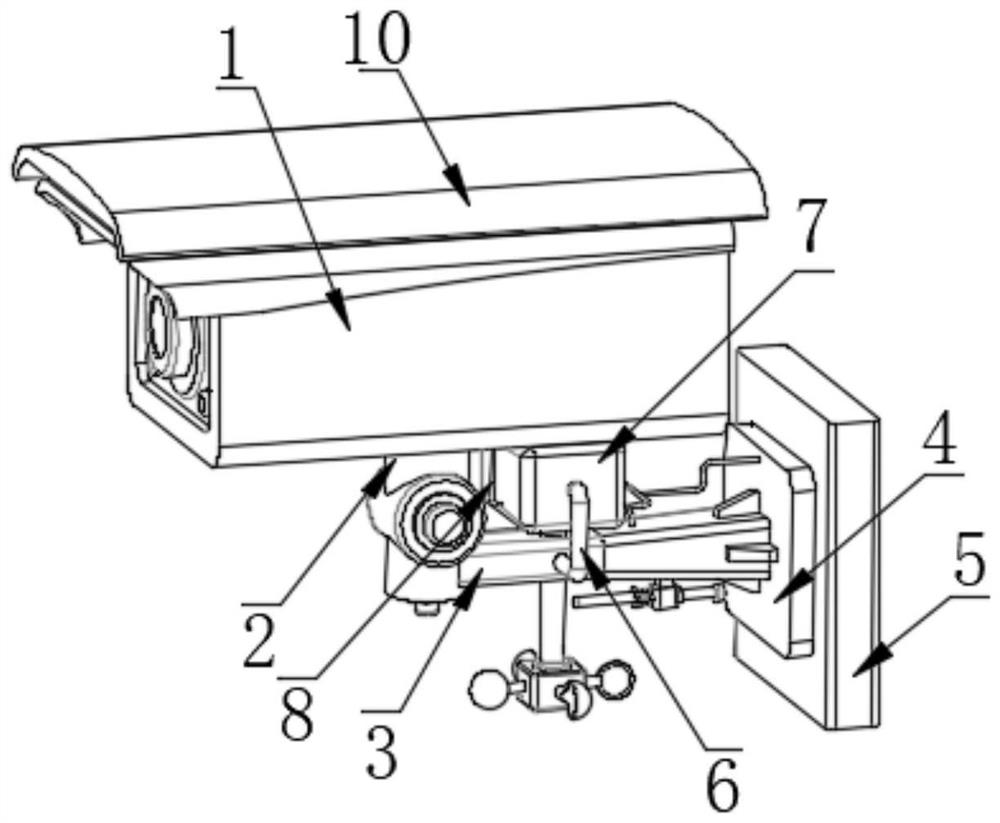

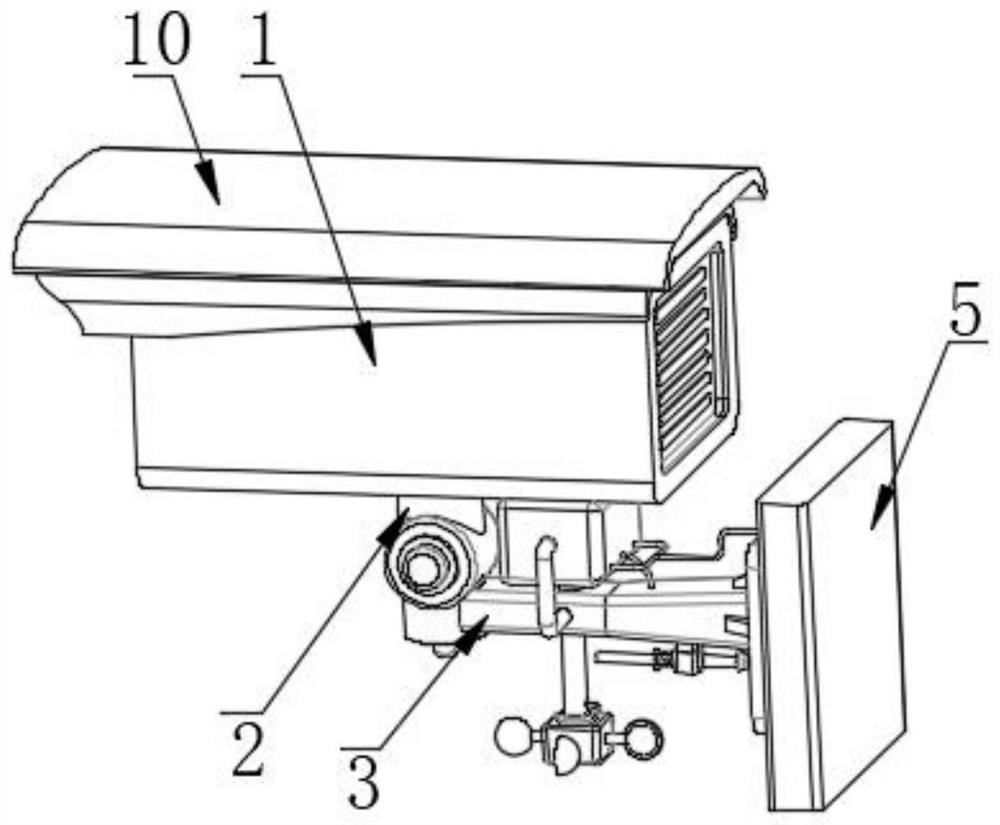

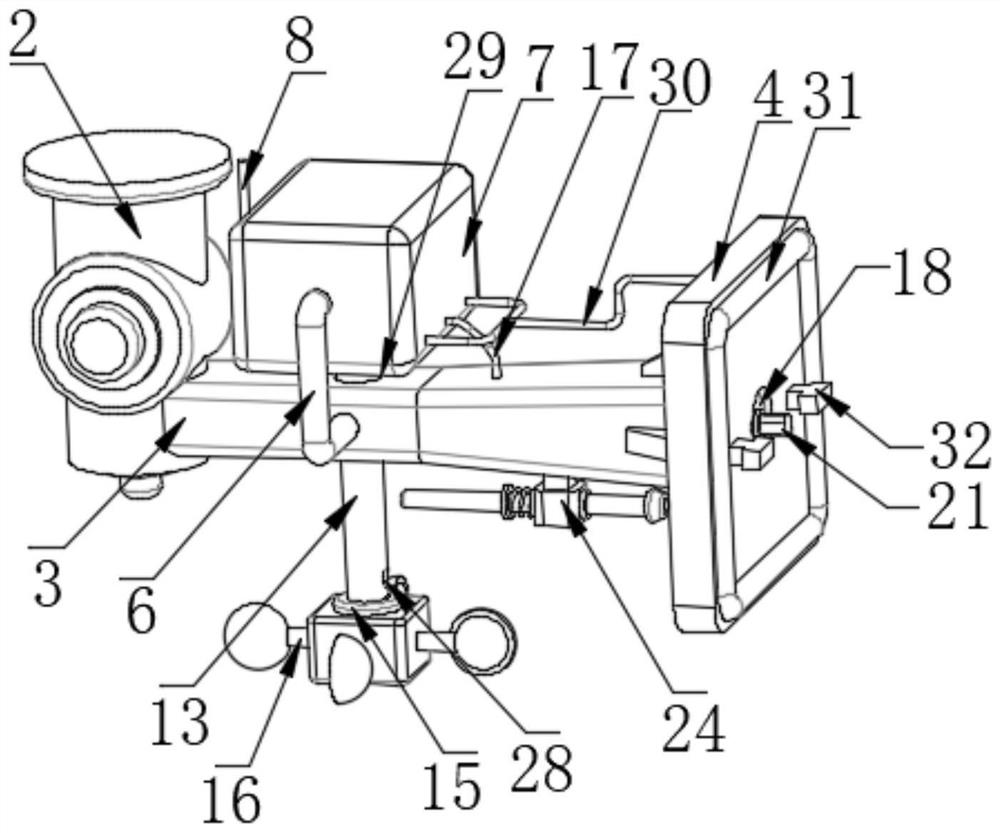

Protective building security and protection monitoring equipment with quick-mounting structure

PendingCN114576534AEasy and quick assemblyShort operating times for installationTelevision system detailsColor television detailsConstruction engineeringMonitor equipment

The invention discloses a protective building security monitoring device with a quick-mounting structure, and particularly relates to the technical field of building construction.The protective building security monitoring device comprises a monitoring device body, an adjusting support is arranged on the lower surface of the monitoring device body, and the right side face of the adjusting support is fixedly connected with the left end of a supporting rod; the right end of the supporting rod is fixedly connected with the left side face of a connecting base. By arranging the mounting plate, the connecting seat, the guide limiting block, the guide connecting groove, the piston barrel, the piston frame, a second connecting pipe, a first piston plate, a second piston plate, a second piston rod, a first magnetic block and a second magnetic block, the second piston plate and the second piston rod move close to the first limiting groove at the same time; according to the device, the assembly operation is fast and simple, it is guaranteed that the installation operation time at a high position is short, and potential safety hazards existing in the operation process are reduced.

Owner:湖北华恒天久建设工程有限公司

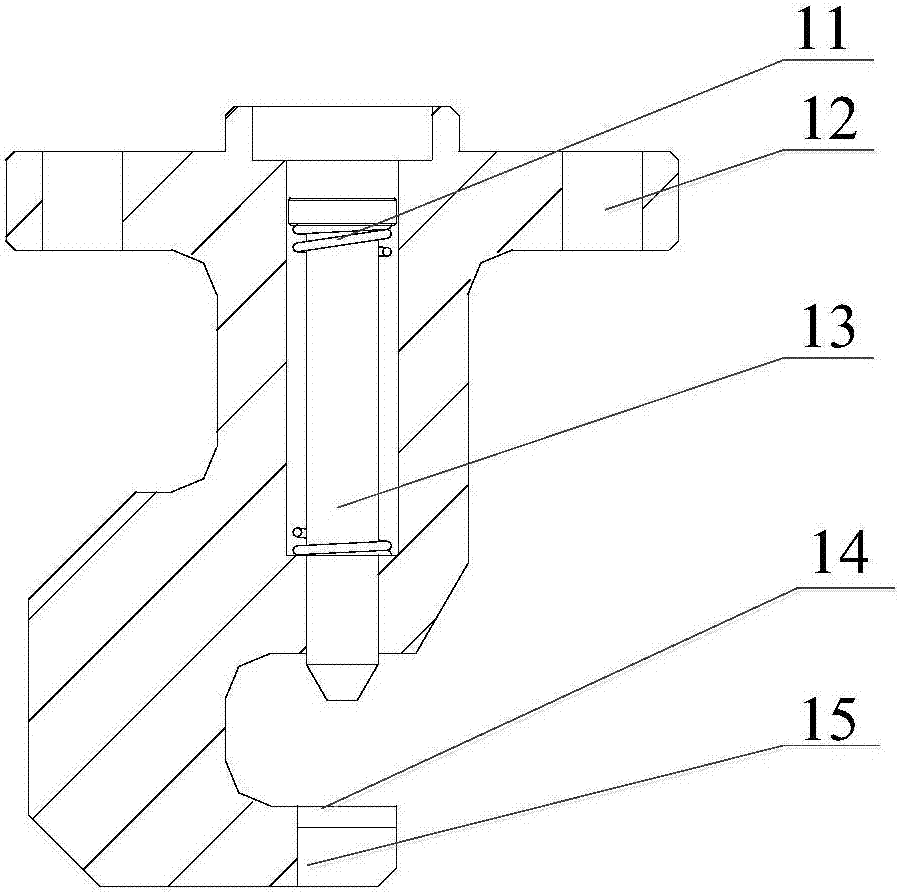

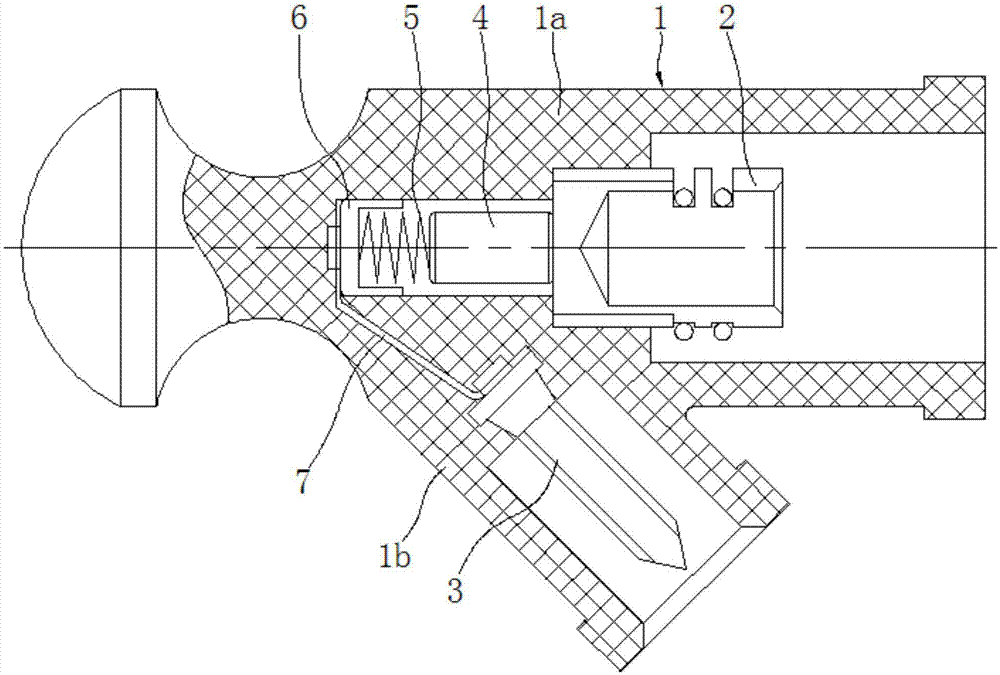

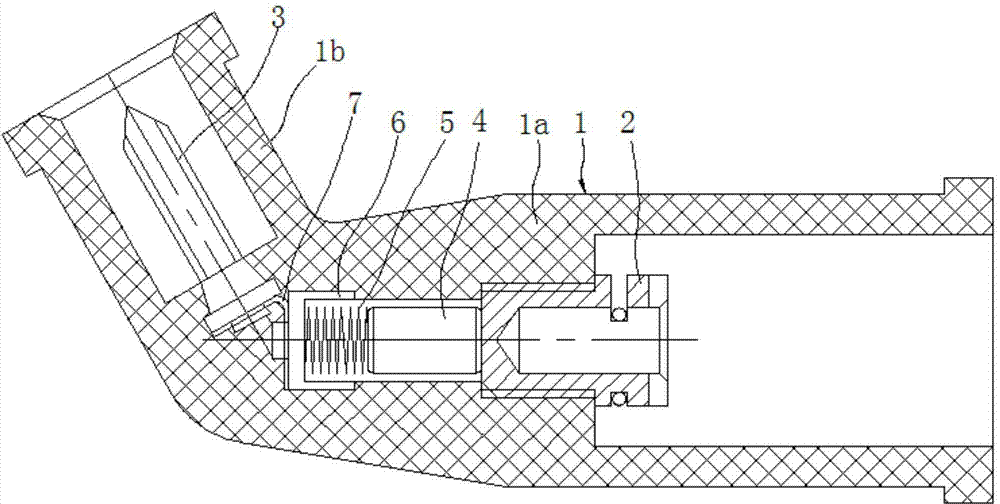

Spark plug cap production technology

InactiveCN104325600AEasy to processImprove reliabilitySparking plugs manufactureElectrical resistance and conductanceRoom temperature

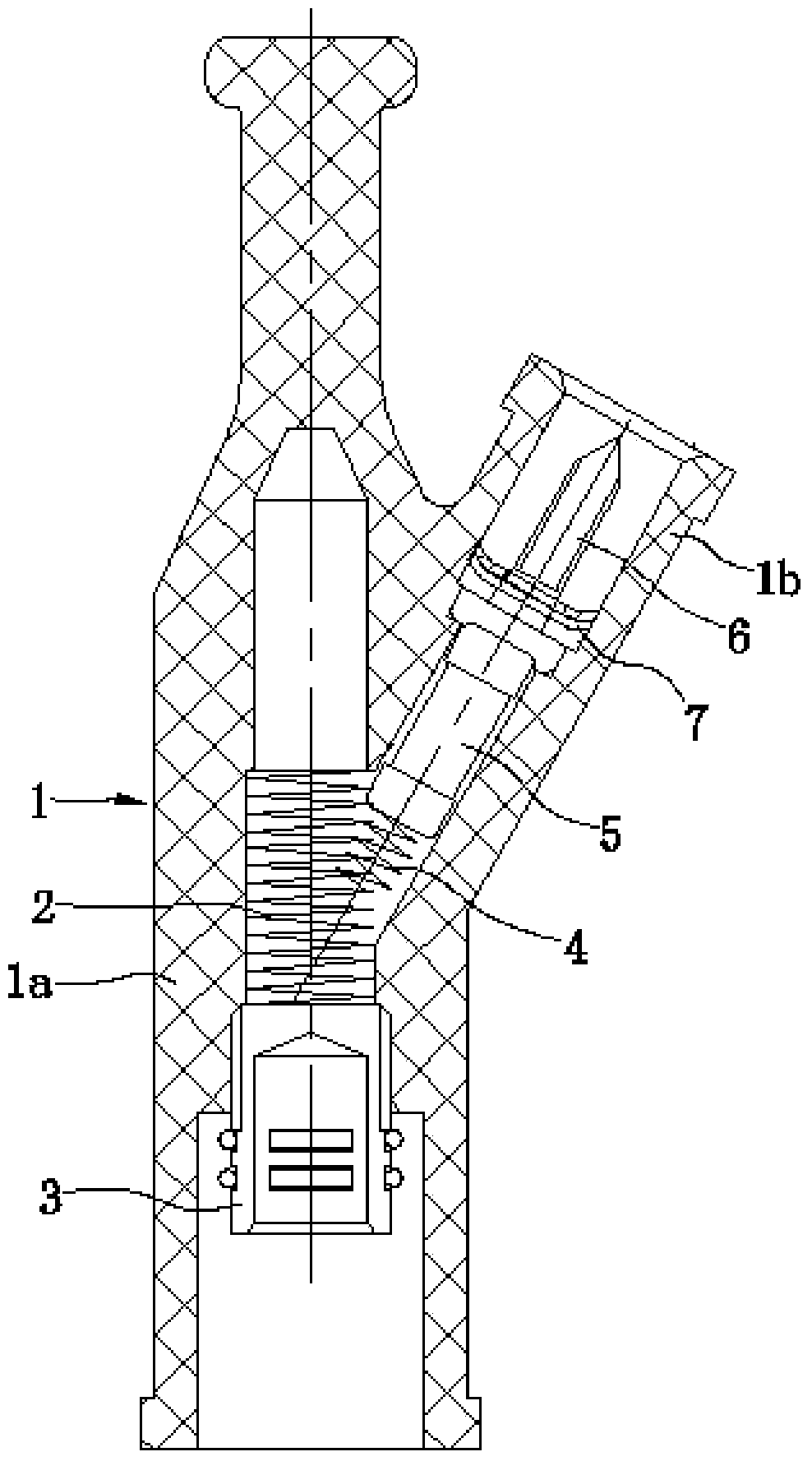

The invention discloses a spark plug cap production technology. The production technology comprises the following steps: (1) fixedly connecting a resistor cap (6) and a self-tapping screw (3) together through a connection sheet (7) at a room temperature so as to form a screw assembly; (2) installing the screw assembly to a mould core, then placing the mould core into a mould, and producing a body (1) through an injection moulding technology; (3) loading a spring (5) and a resistor (4) into the main pipe (1a) of the body (1) in sequence at a room temperature, and finally screwing a conductive cap (2) into the main pipe (1a) of the body (1). The technology is simple, the steps are simplified, and the production efficiency is high. The assembly can be achieved at a room temperature, thus the workers will not be burned, and the bad conductivity of products is effectively prevented. Furthermore, the contact area between the spring and the resistor cap is large, thus the contact performance is better, and the conducting performance is further improved.

Owner:CHONGQING CONGREN ELECTROMECHANICAL

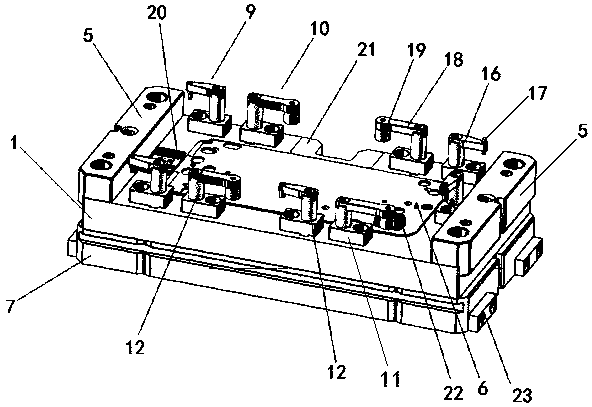

Band laser welding tool for laser welding equipment

PendingCN107900541AMeet the needs of positioning transplantingMachining accuracy is easy to guaranteeLaser beam welding apparatusEngineeringSlide plate

The invention discloses a Band laser welding tool for laser welding equipment. The Band laser welding tool for the laser welding equipment comprises a tool substrate; three single-welding stations andone double-welding station are arranged on the lower surface of the tool substrate; copper sleeves are arranged in the welding stations; five NUT rotary pressing mechanisms and four product rotary pressing mechanisms are arranged in the tool substrate; the NUT rotary pressing mechanisms are positioned on the edges of the welding stations; the product rotary pressing mechanisms are positioned on one sides of the welding stations; heightening blocks and product positioning pins are arranged on the upper surface of the tool substrate; the bottom of the tool substrate is bonded with a slide railbaseplate through substrate dowel pins; and the slide rail baseplate is provided with avoiding holes corresponding to the single-welding stations, the double-welding station, the NUT rotary pressing mechanisms and the product rotary pressing mechanisms. The Band laser welding tool for the laser welding equipment has the advantages of easy guarantee of the machining precision, high laser welding efficiency, simple and fast assembly operation, short maintenance period and the like, and meets the product positioning and transplanting demands in full-automatic laser welding equipment.

Owner:苏州茂特斯自动化设备有限公司

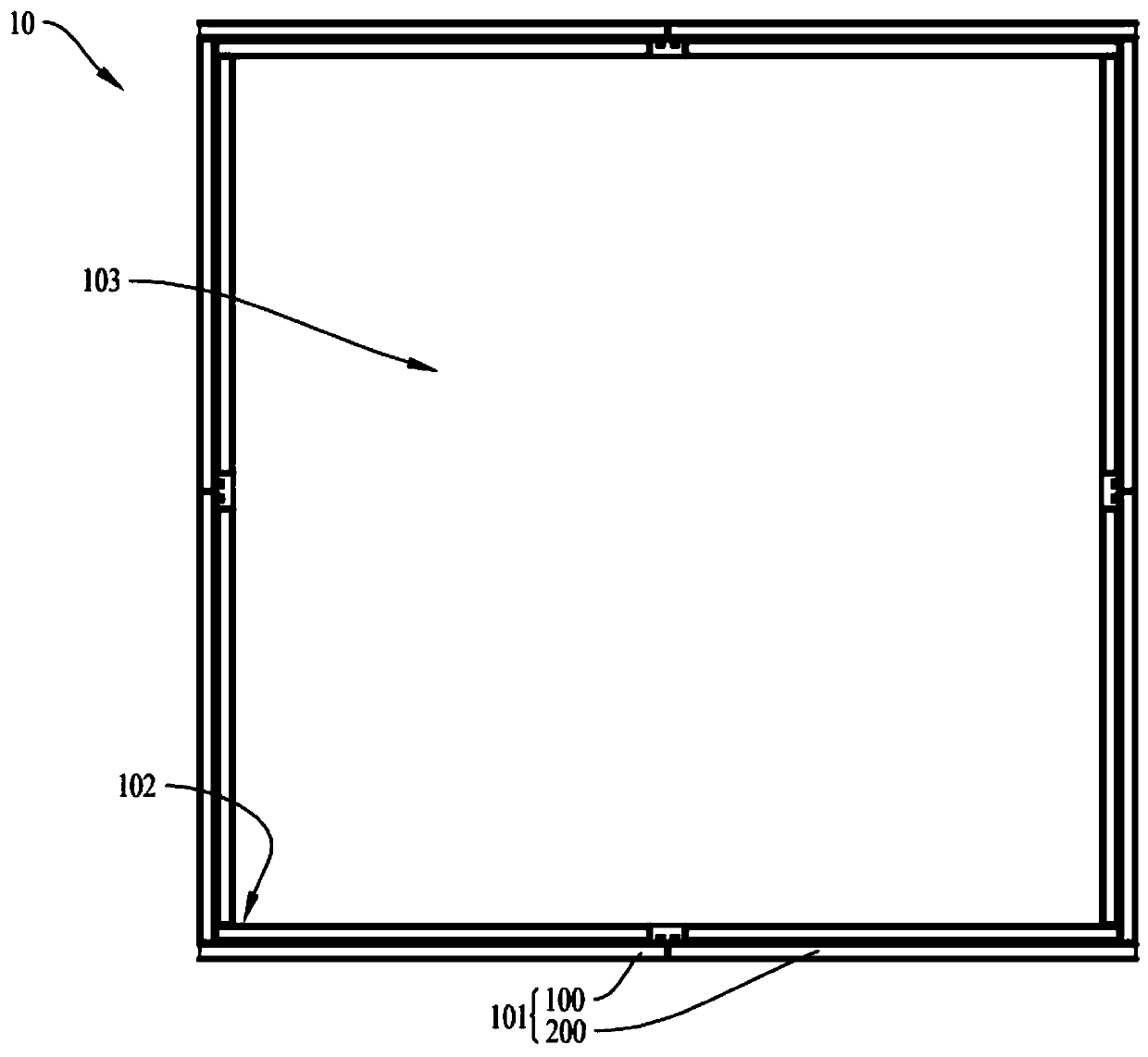

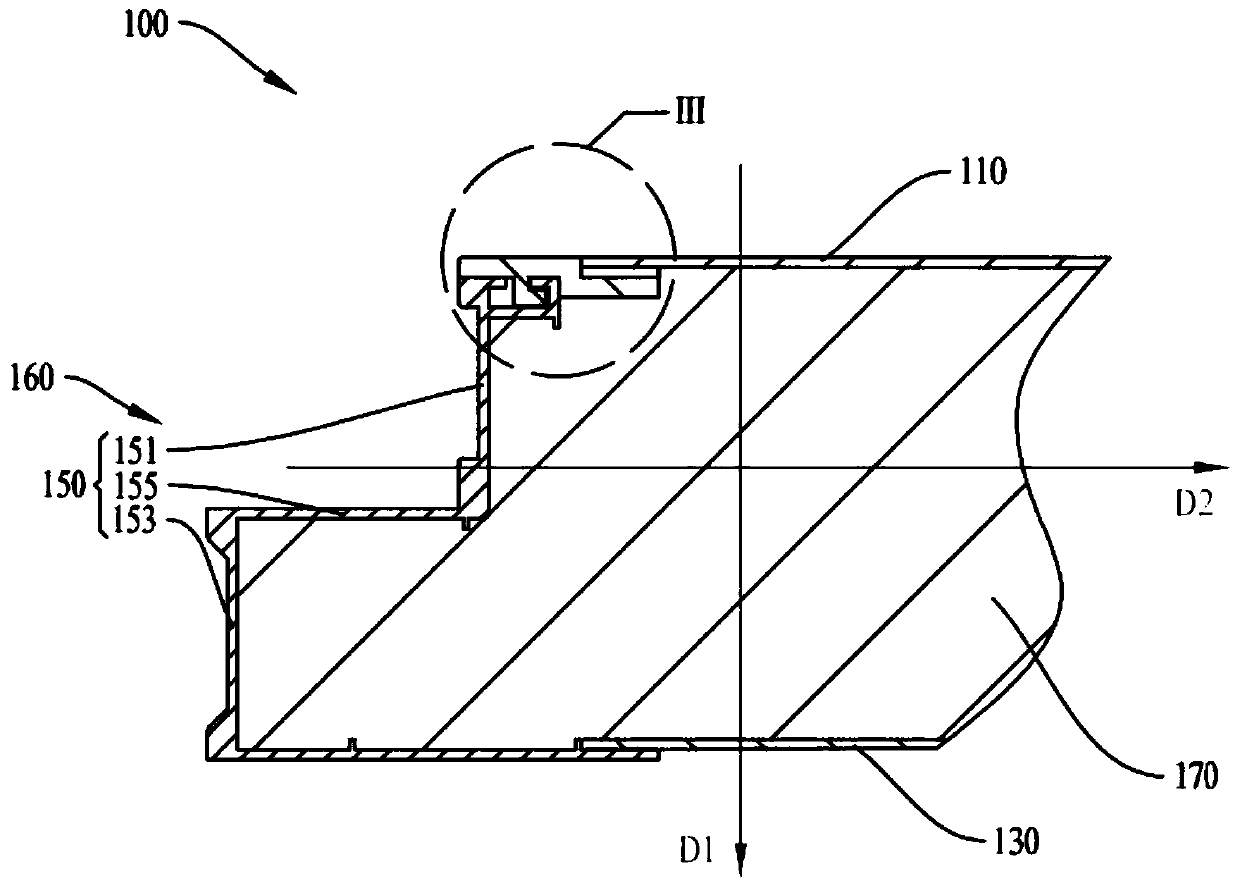

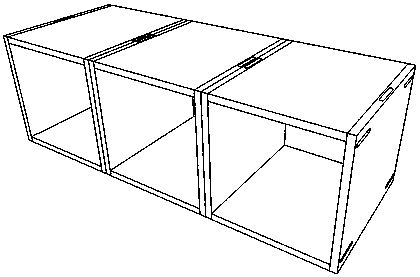

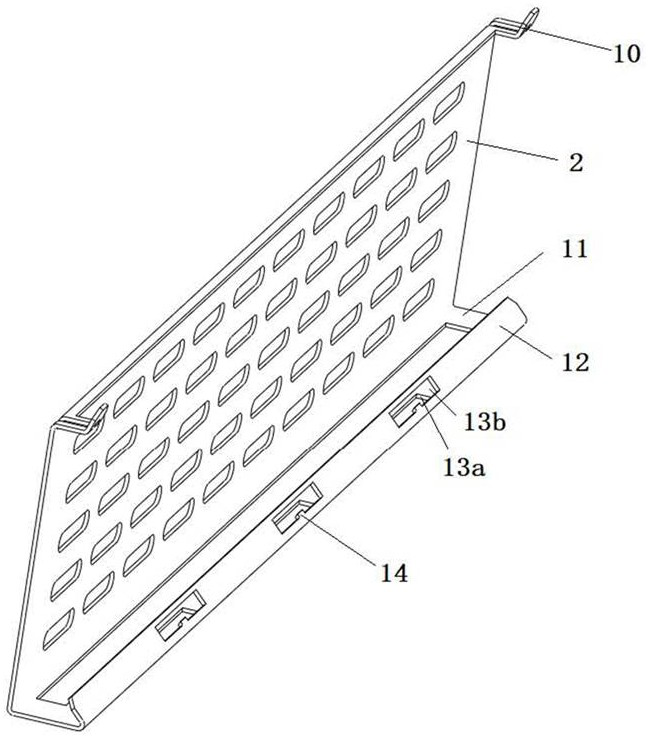

Heat insulating plate assembly and heat insulating box body

PendingCN111256355AEasy and quick assemblyModularHeating and ventilation casings/coversPhysicsEngineering

The embodiment of the invention provides a heat insulating plate assembly. The heat insulating plate assembly comprises a first panel, a second panel, a connecting supporting frame and a heat insulating layer. The first panel and the second panel are oppositely arranged at intervals, the connecting supporting frame is connected between the first panel and the second panel, and a containing grooveis defined by the connecting supporting frame, the first panel and the second panel. The connecting supporting frame comprises a first connecting part, a second connecting part and a third connectingpart, the third connecting part is connected between the first connecting part and the second connecting part, the first connecting part and the second connecting part are staggered, a splicing portion is formed at one end of the heat insulating plate assembly, and the containing groove is filled with the heat insulating layer. The containing groove is filled with the heat insulating layer of theheat insulating plate assembly, so that a heat insulating effect is provided. The splicing portion is formed at the position, at one end of the heat insulating plate assembly, of the connecting supporting frame, so that multiple heat insulating plate assemblies are modularly spliced into a heat insulating box body, and the assembly process of the heat insulating plate assemblies is simple and convenient. The embodiment of the invention further provides the heat insulating box body.

Owner:SHENZHEN ITEAQ NETWORK POWER TECH CO LTD

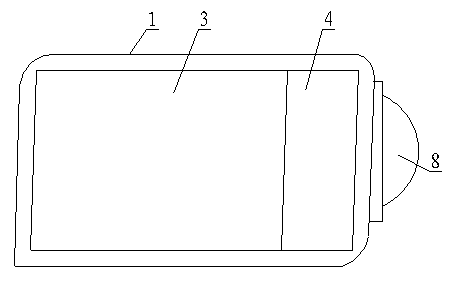

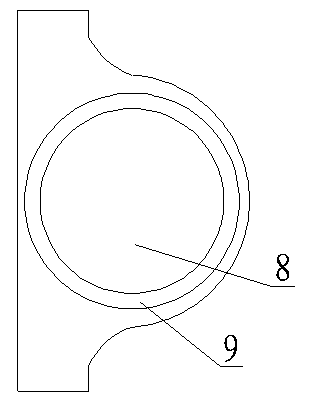

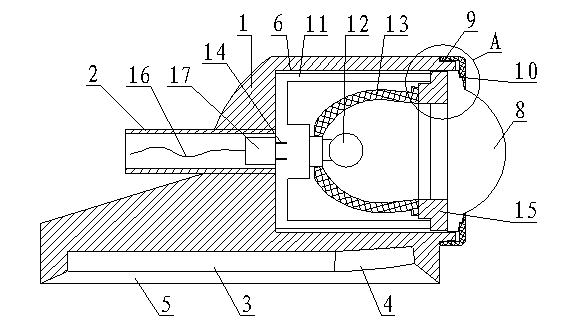

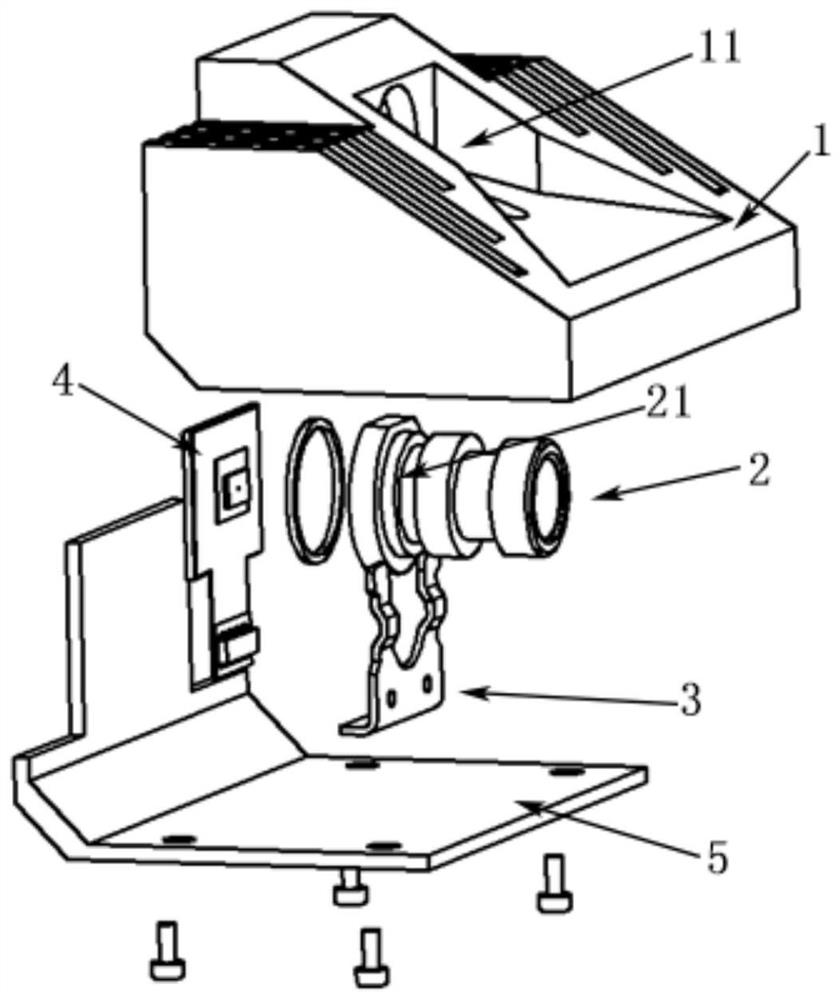

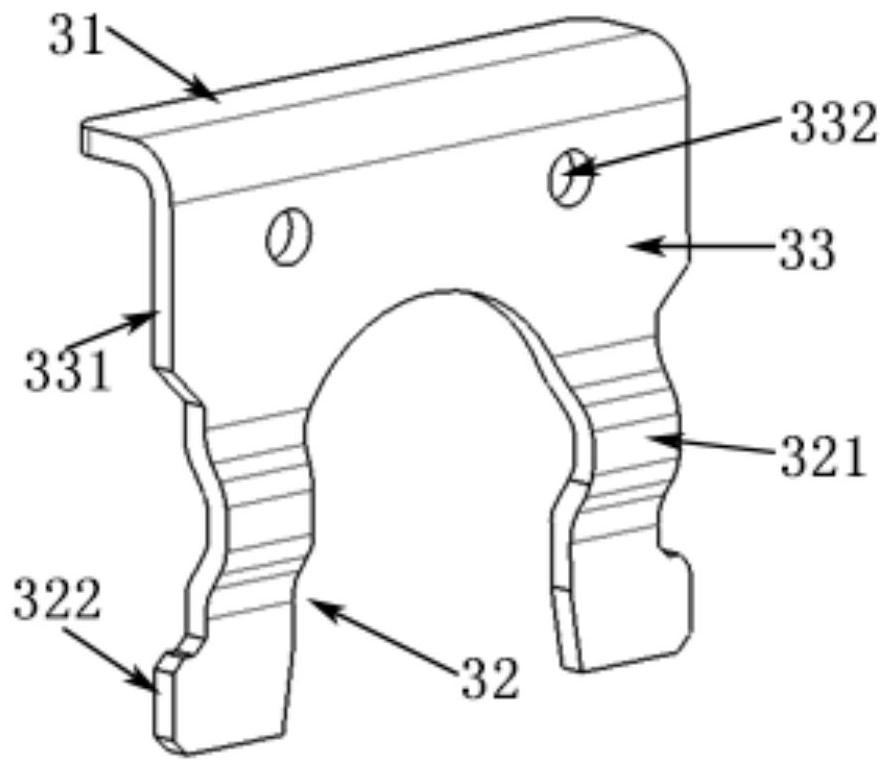

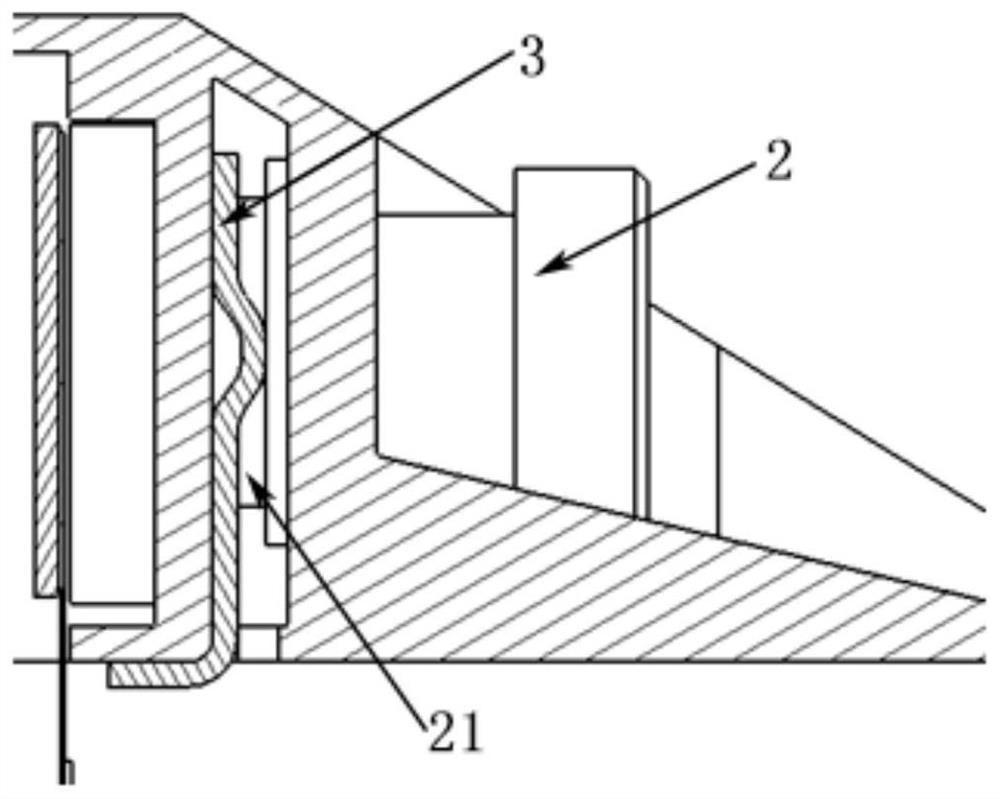

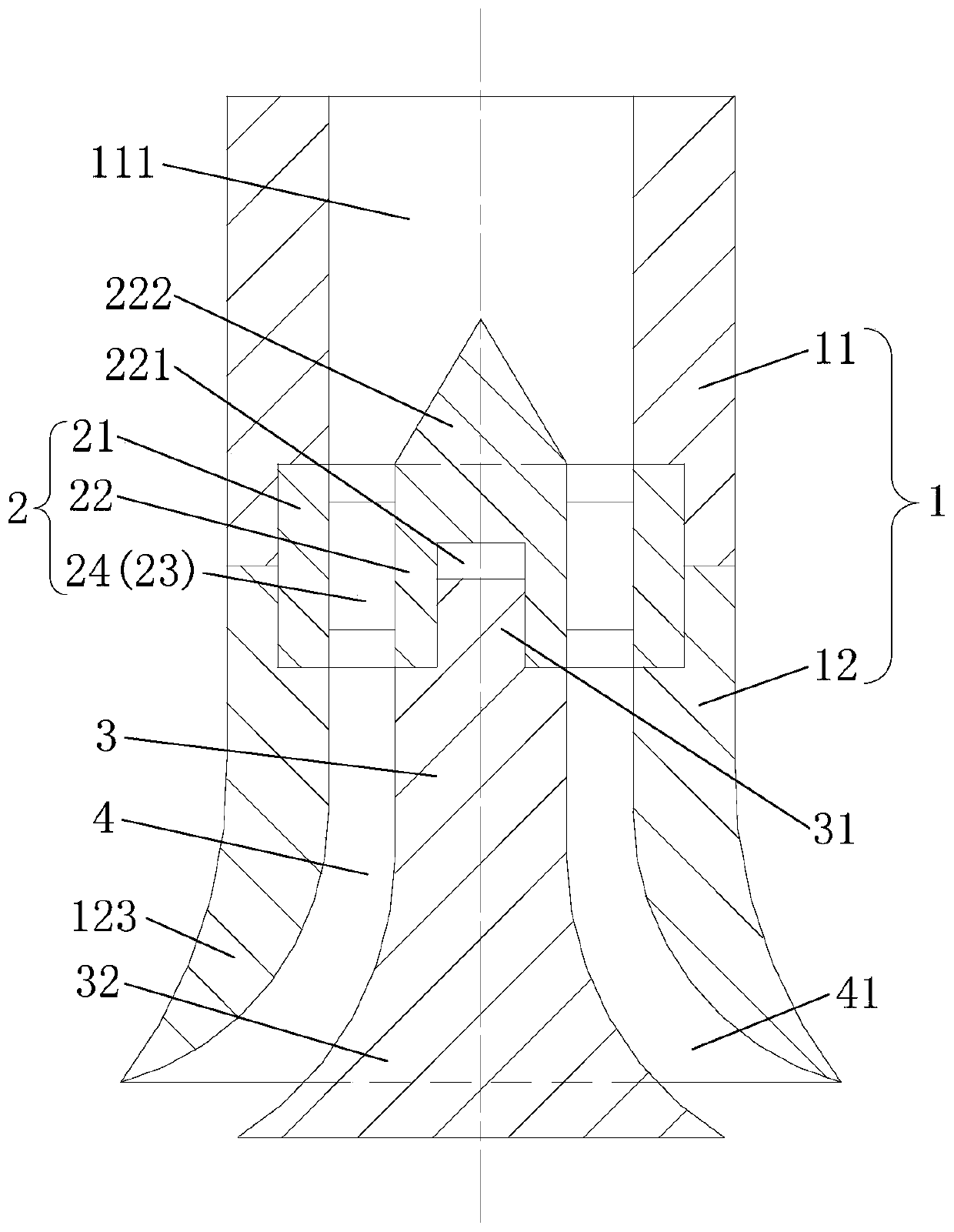

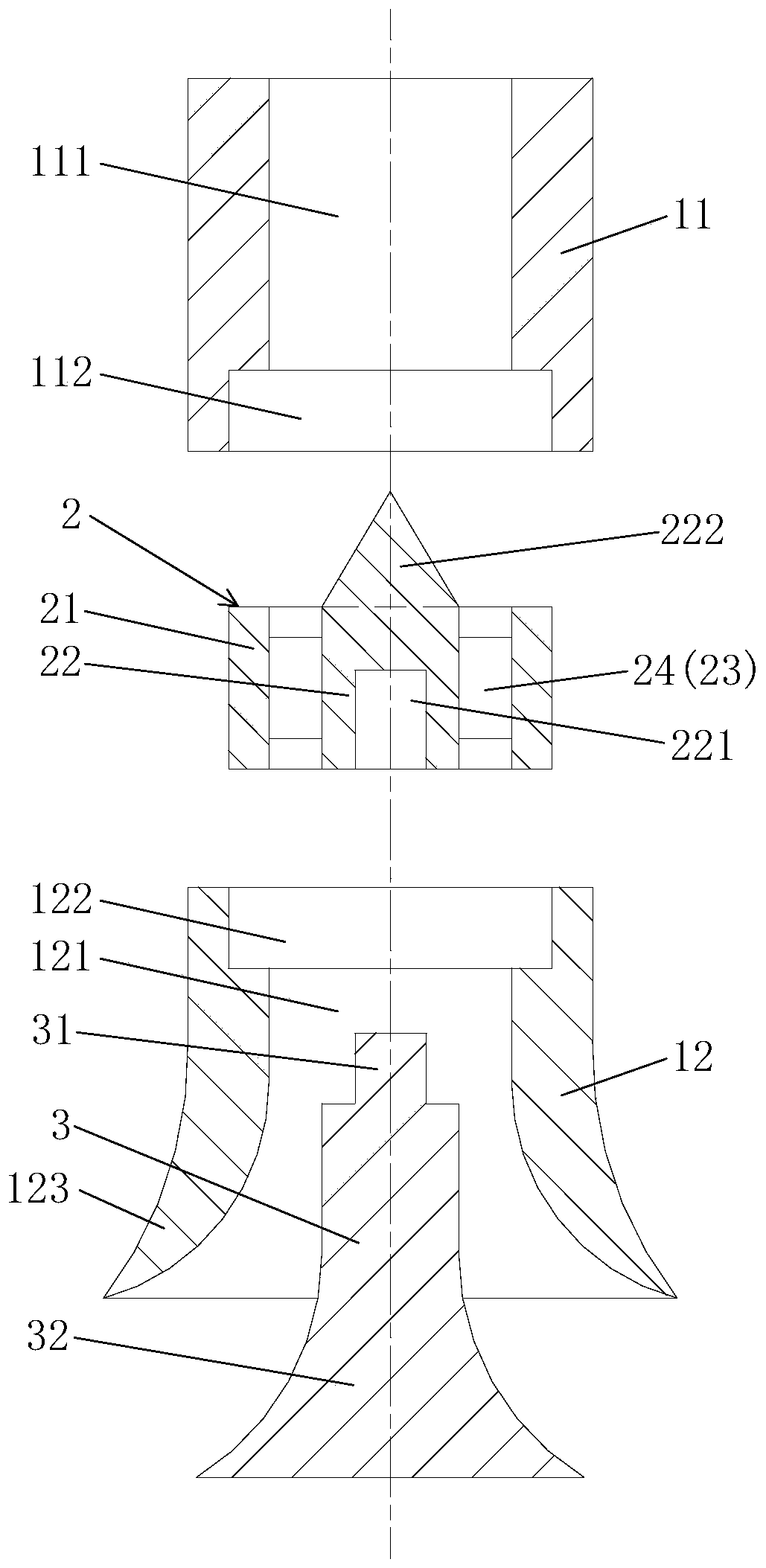

Camera module structure

PendingCN113965667AGuaranteed qualityGuaranteed service lifeTelevision system detailsColor television detailsImaging qualityEngineering

The invention relates to a camera module structure which comprises an upper shell (1) and a lens (2), the upper shell (1) is provided with a containing part (11), the lens (2) is installed in the containing part (11), the camera module structure is characterized by further comprising a clamping spring (3), the clamping spring (3) comprises a pressing part (31) and a clamping part (32), a guide groove (12) is formed in the upper shell (1), a clamping groove (21) is formed in the peripheral wall of the lens (2). And the clamping part (32) is clamped in the clamping groove (21) of the lens along the guide groove (12). The camera module structure is convenient to assemble, does not have the problems of vibration, falling off, breakage and the like compared with screw connection, glue connection and the like, and is good in imaging quality and long in service life.

Owner:ZHEJIANG SUNNY SMARTLEAD TECH CO LTD

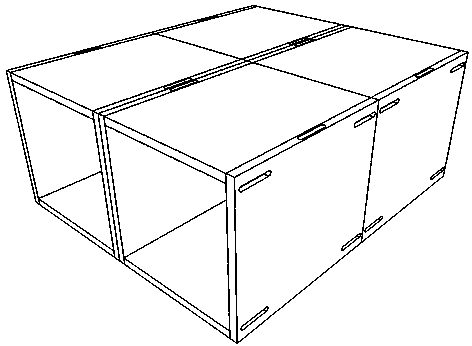

Quick self-disassembled and assembled snap joint type furniture connector and assembling method

PendingCN108953320ASimple processingEasy and quick assemblySheet joiningFurniture joiningAdhesiveJoints types

The invention provides a quick self-disassembled and assembled snap joint type furniture connector and an assembling method. The connector structurally comprises a pair of slot pieces and a snap jointpiece, wherein two slot positions, two screw hole positions and two guide slots are formed on the upper end surface of each slot piece, the two slot positions are arranged parallelly in the middle ofthe upper end surface of each slot piece, the two screw hole positions are arranged at two ends of the length direction of the upper end surface of each slot piece 1 and penetrate the upper and lowerend surfaces of each slot piece 1, and the two guide slots are symmetrically formed in the upper sides of the two screw hole positions. The connector provided by the invention has the advantages that1) the connector is simply and rapidly assembled, so that the connector can be disassembled and assembled quickly, and the mounting and packaging and transporting costs are lowered; 2) the connectorhas relatively high mechanical properties and supporting ability, and is safe and reliable; 3) the connector is assembled without an adhesive and tools, so that the connector is green and environment-friendly and healthy and safe; and 4) the connector has no exposed parts, so that the attractiveness of a product is kept, and the demand of autonomously disassembling and assembling the connector bya user is met.

Owner:GUANGDONG YIHUA TIMBER IND

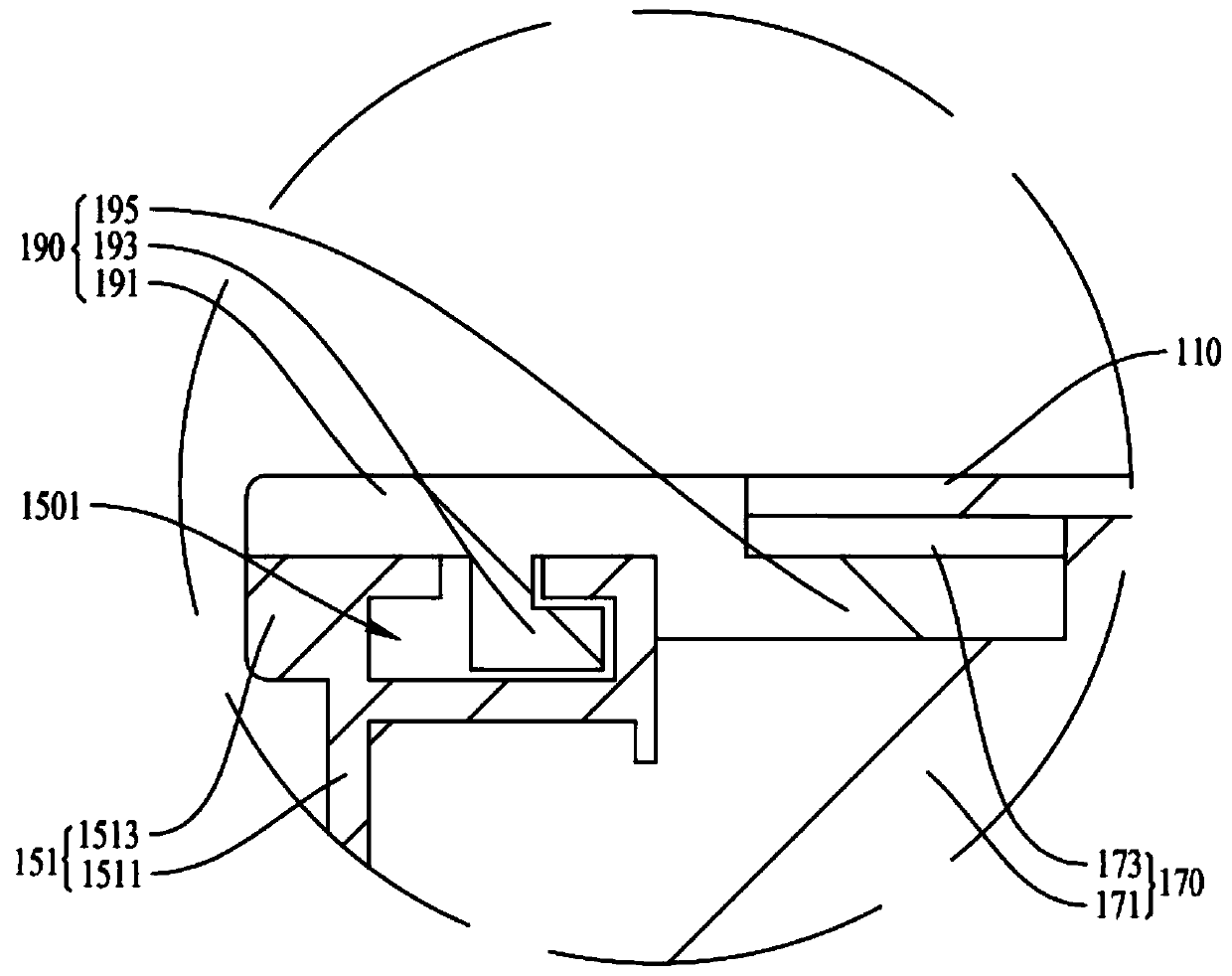

Detachable leg structure and glasses including structure

The invention provides a detachable leg structure and a pair of glasses including the structure, and the detachable leg structure comprises legs, leg root containing portions rotatably mounted at theglasses leg connection portions, and leg root limit portions, wherein the legs are provided with fixing heads; the leg root containing portions are each formed with a containing cavity for containingeach of the leg fixing heads; the leg root limit portions are mounted at the mounting positions of the leg root containing portions at the glasses leg connection portions, the leg root containing portions are built in the leg root limit portions, the leg root limit portions are each provided with an insertion and take-off opening toward the folding direction of the legs and a leg fixing head blocking portion disposed at the upper portion of each of the leg root limit portions, the leg fixing head blocking portions are provided with unfolding and retracting notches for moving the legs from thefolding direction toward the unfolding direction, and the unfolding and retracting notches communicate with the insertion and take-off openings. This kind of glasses can quickly and easily complete the disassembly and assembly work of the legs.

Owner:郭靖宇

Cat bed

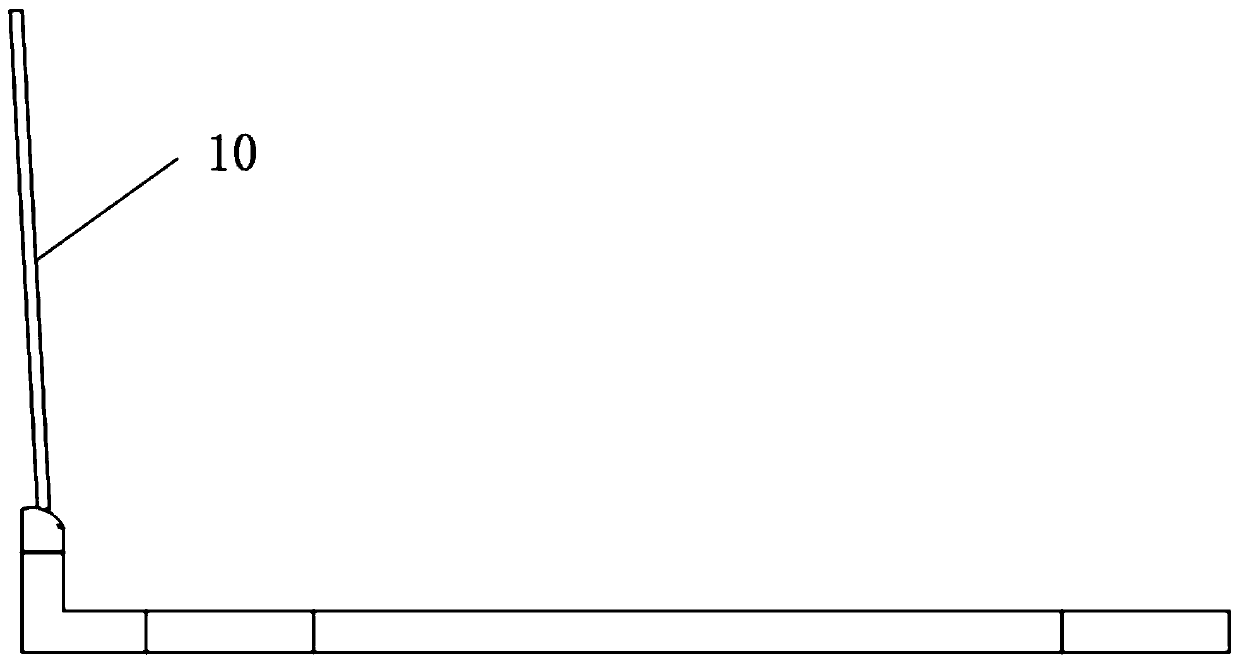

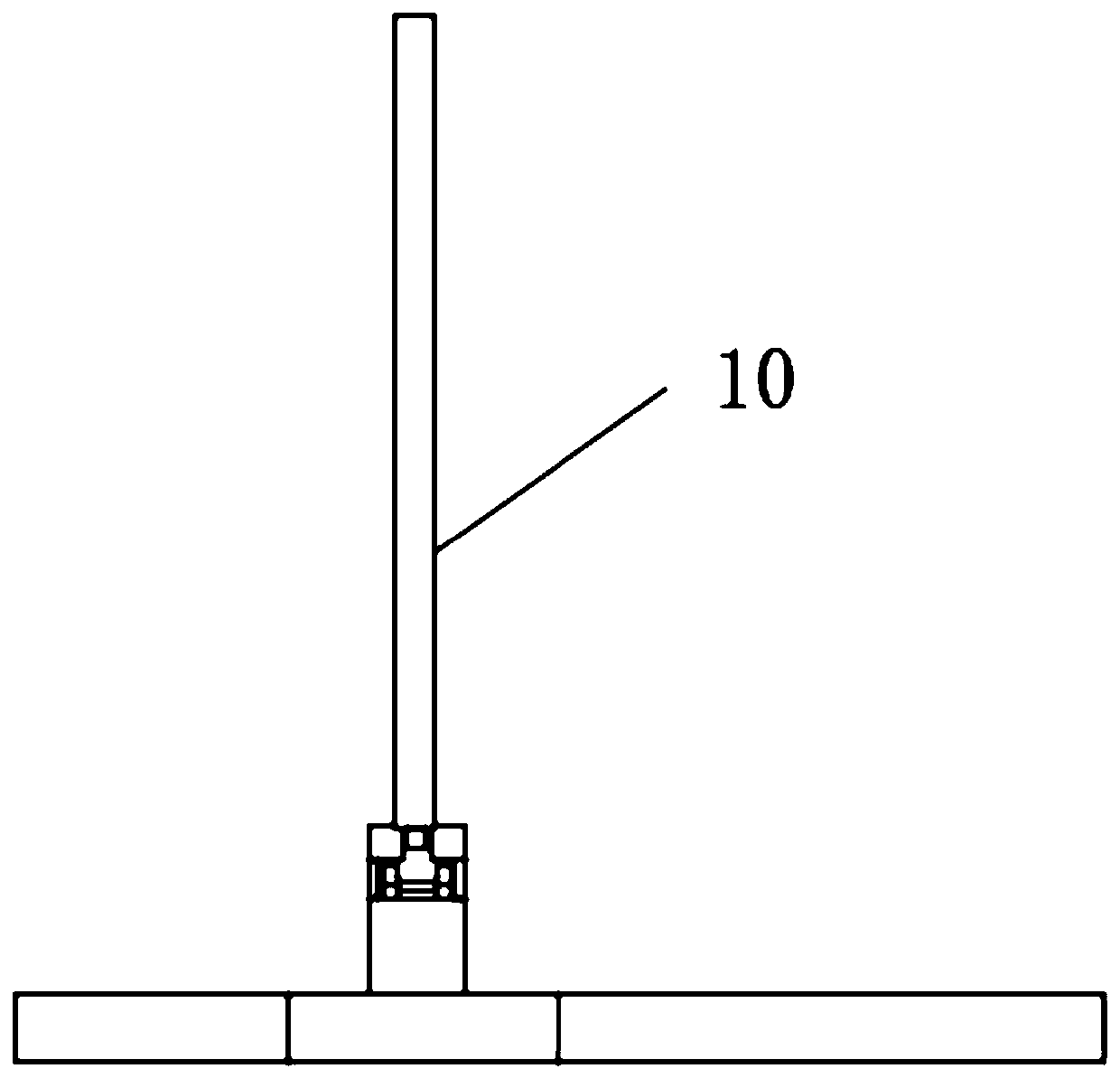

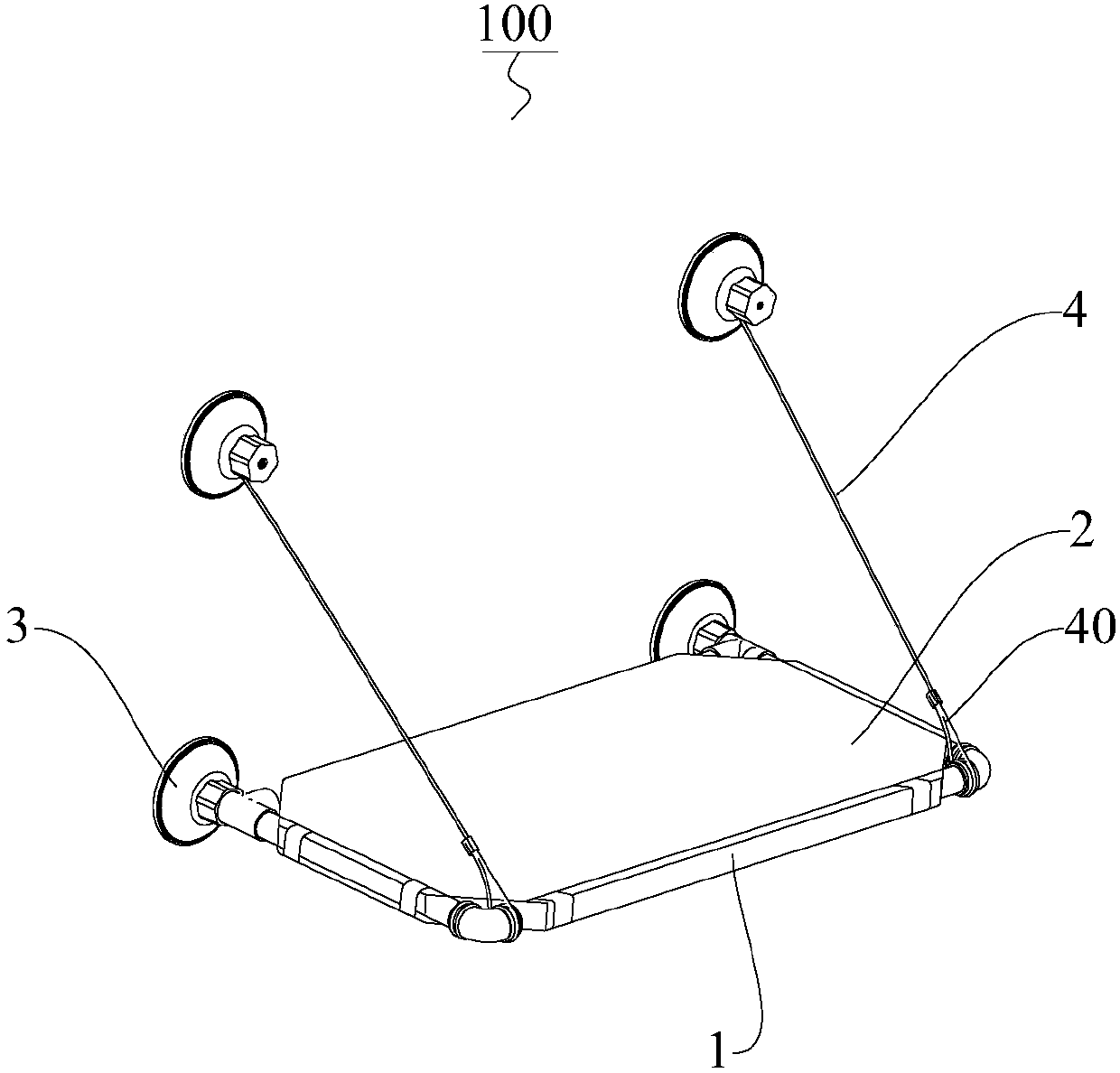

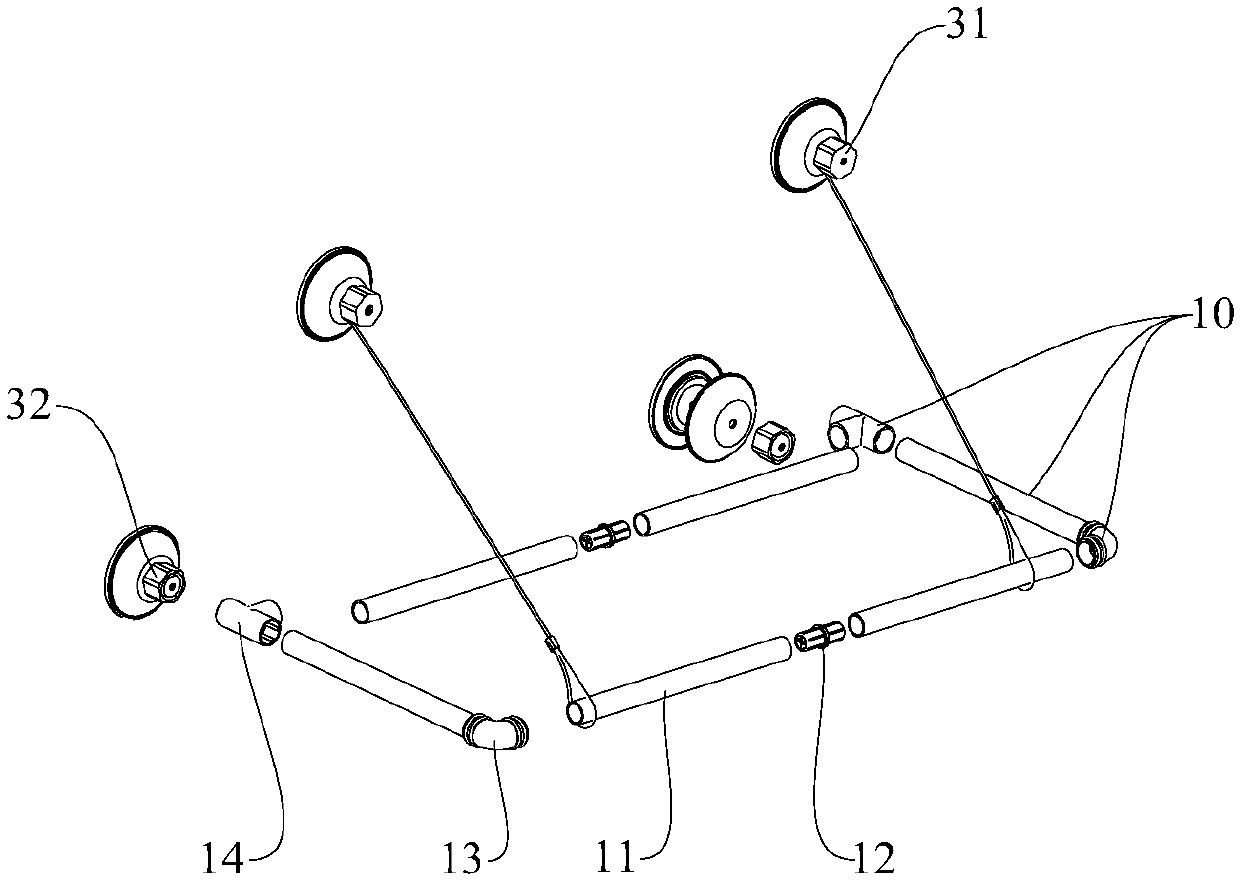

InactiveCN107801644AEasy and quick assemblyEasy and quick disassemblyAnimal housingStructural engineeringGlass window

The invention discloses a cat bed. The cat bed comprises a cat bed framework, a bed surface, sucking cups and diagonal pulling devices, wherein multiple sucking cups are located on the same plane andare fixed to a wall body or glass window in an upper-lower layer way, the cat bed framework is of a frame structure and is horizontally arranged, one end of the inner side of the frame structure is plug-connected to the sucking cups of the lower layer, the bed surface is laid on the frame structure, an annular sleeve is arranged at one end of each diagonal pulling device and sleeves one end of theframe structure, the other end of each diagonal pulling device extends towards the sucking cups at a certain angle and is fixedly connected with each sucking cup of the upper layer. The cat bed has the advantages of being convenient to assemble and disassemble, safe, hygienic and convenient to use.

Owner:JIANGSU ZHONGHENG PET ARTICLES JOINT CO LTD

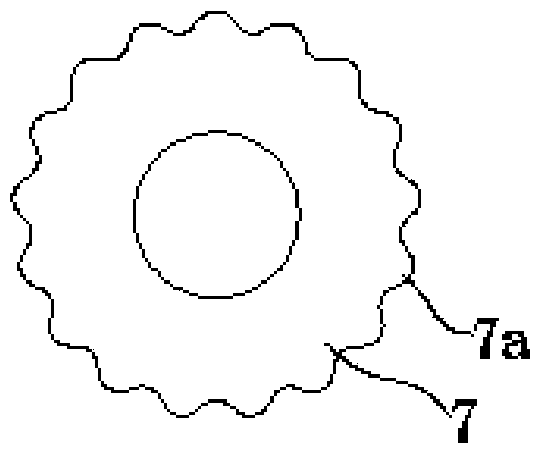

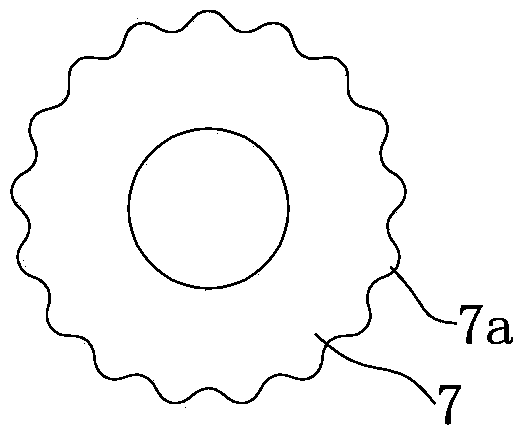

General engine spark plug cap

The invention discloses a general engine spark plug cap. An electric conductive cap (3) is in screw thread fit with a min pipe (1a). A screw (6) is an outer hexagon self-tapping screw. Grooves are symmetrically formed in the two ends of a resistor (5). The end of a supporting pipe spring (4) stretches into the groove of one end of the resistor (5), and the other end of the resistor (5) stretches into a countersunk groove in the head of the screw (6). A plum-shaped sheet (7) is fixedly arranged at the position, close to the head of the screw, of the screw (6) in a sleeved mode. The edge of the plum-shaped sheet (7) deforms and is bent towards the tip of the screw (6) to form a circle of cambered surface turnup, and outer teeth (7a) are evenly distributed on the cambered surface turnup in the circumferential direction. The general engine spark plug cap can be assembled at normal temperature, operation workers are prevented from being scalded, residues in the body are easy to remove, and poor breakover of products can be prevented effectively; the contact area between the resistor and the supporting pipe spring and the contact area between the resistor and the screw are large, the contact performance is better, and the therefore breakover performance can be further improved.

Owner:CHONGQING CONGREN ELECTROMECHANICAL

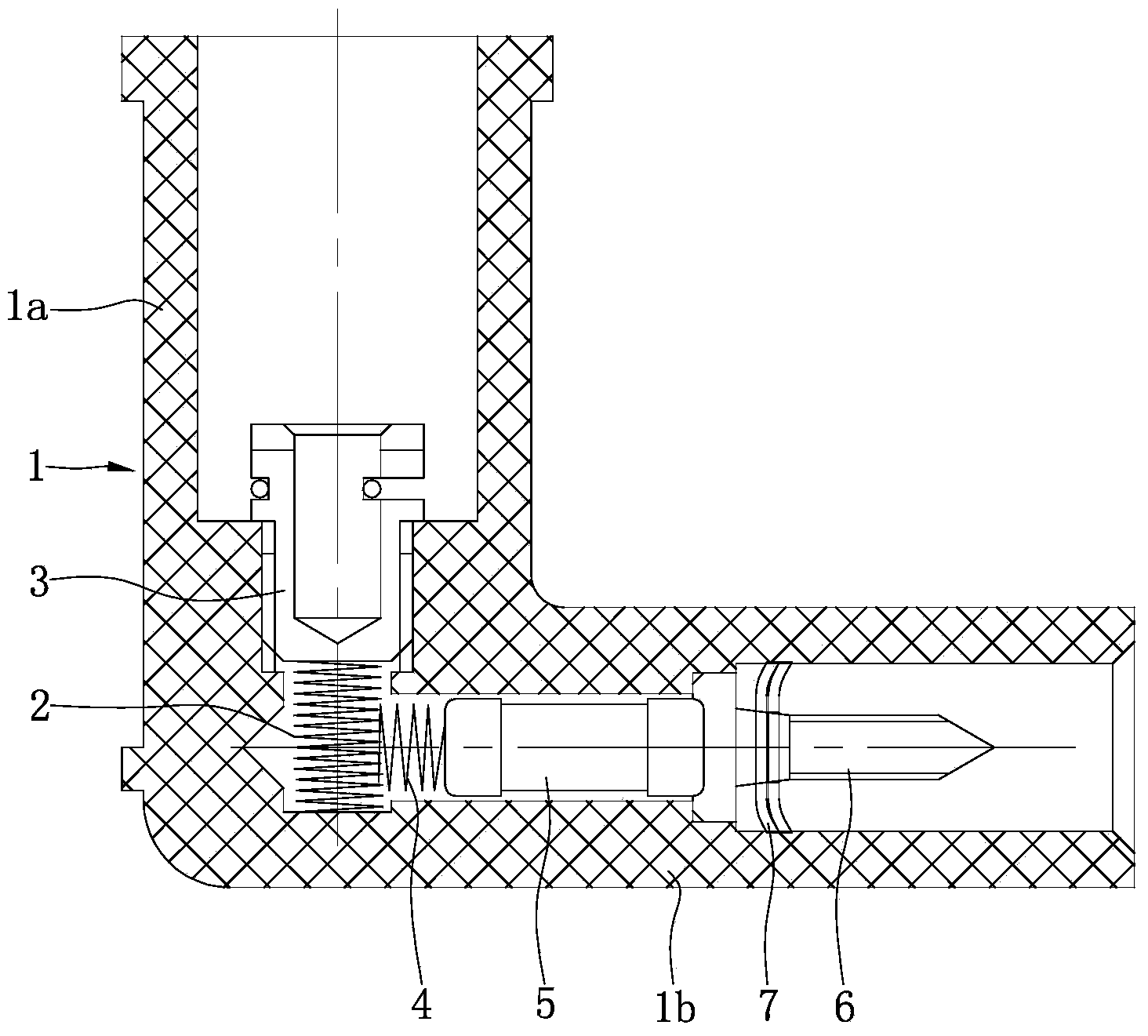

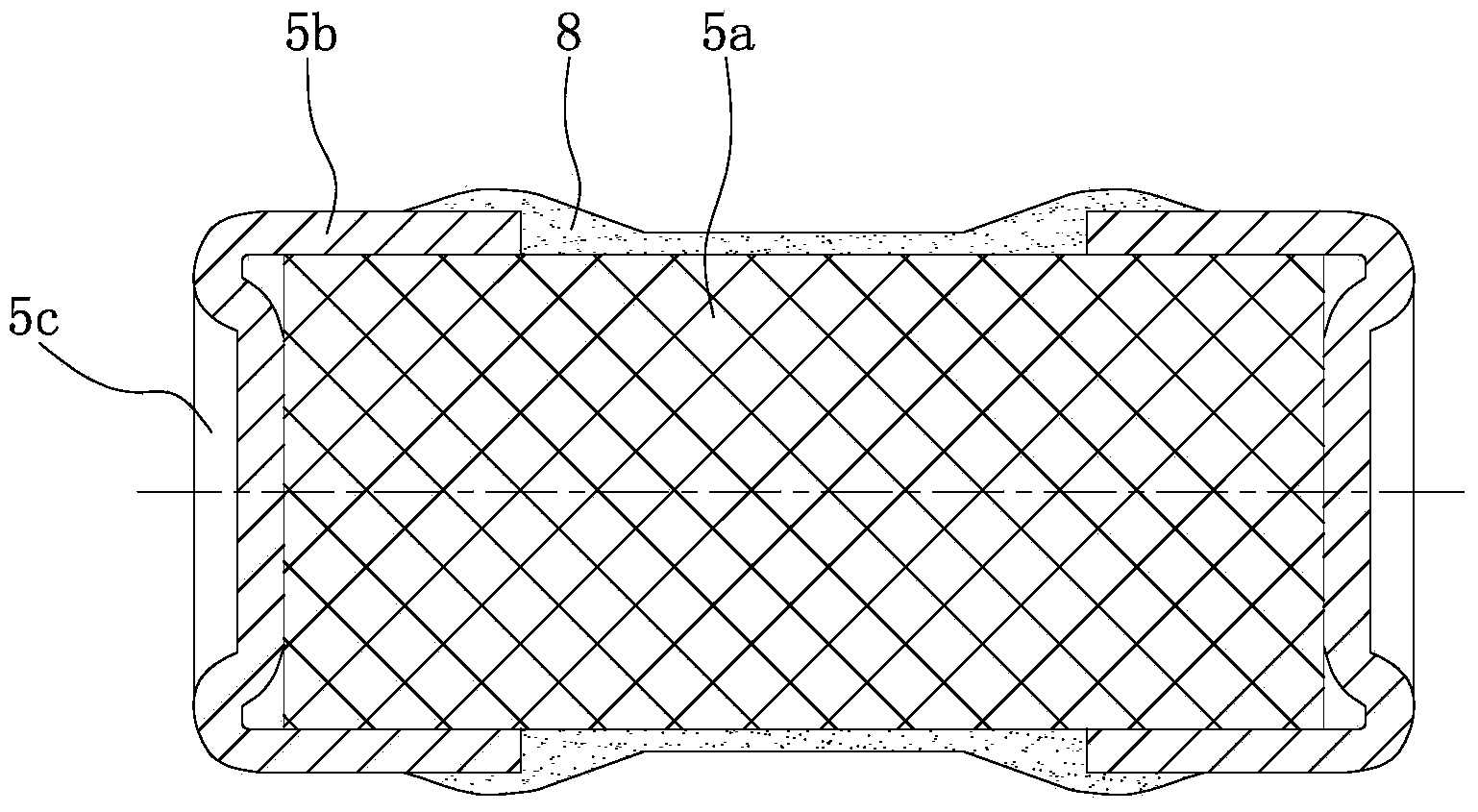

Ceramic resistor type spark plug cap of motorcycle

ActiveCN104242062ATight jointIncrease contact areaSparking plugsElectrical resistance and conductanceMetal

The invention discloses a ceramic resistor type spark plug cap of a motorcycle. A body (1) is in an L shape and is composed of a first straight pipe (1a) and a second straight pipe (1b), wherein the first straight pipe (1a) and the second straight pipe (1b) are perpendicular to each other. A first spring (2) and a conductive cap are mounted in the first straight pipe (1a). A second spring (4), a resistor (5) and a screw (6) are mounted in the second straight pipe (1b) from inside to outside in sequence. The screw (6) is an outer hexagon self-tapping screw. The resistor (5) is composed of a ceramic rod (5a) and metal caps (5b) at the two ends of the ceramic rod (5a) in a sleeved mode. The ceramic resistor type spark plug cap of the motorcycle is simple in structure, easy to assemble and high in assembly efficiency; on one hand, assembly can be completed at normal temperature, operation workers are prevented from being scalded, residues in the body are easy to remove completely, and poor breakover of products can be prevented effectively; on the other hand, the contact area between the resistor and the spring and the contact area between the resistor and the screw are large, the contact performance is better, and the breakover performance can be further improved.

Owner:CHONGQING CONGREN ELECTROMECHANICAL

Spark plug cap screw integration production technology

InactiveCN104325599AEasy to processImprove reliabilityCoatingsElectrical resistance and conductanceRoom temperature

The invention discloses a spark plug cap screw integration production technology. The technology comprises the following steps: (1) fixedly connecting a resistor cap (6) and a self-tapping screw (3) together by a V-shaped connecting sheet (7) to form a screw assembly; (2) making the screw assembly go through a mould to produce a body (1) through an injection mould technology, wherein the body (1) is composed of a straight pipe section (1a) and a cocking-up section (1b); (3) loading a spring (5) and a resistor (4) into the straight pipe section (1a) of the body (1) in sequence at a room temperature, and then screwing a conductive cap (2) into the straight pipe section (1a) of the body (1). The self-tapping screw, the resistor cap, and the connecting sheet are embedded into a mould so as to be moulded with the body. The technology is simple, the steps are simplified, and the production efficiency is high. The post assembly operation is carried out at a normal temperature, and thus the workers will not be burned. The contact area between the spring and the resistor cap is large, so the contacting performance is better, and the conducting performance is further improved.

Owner:CHONGQING CONGREN ELECTROMECHANICAL

Water stop sill and construction method thereof

ActiveCN112096064AEasy and quick assemblyImprove construction efficiencyForms/shuttering/falseworksWater stopScrew thread

The invention discloses a water stop sill and a construction method thereof, and relates to the technical field of decoration construction. The water stop sill comprises a left barrier plate, a plurality of middle barrier plates and a right barrier plate, wherein two support shafts are respectively and fixedly connected to the right side end of the front side wall of each of the left barrier plateand the plurality of middle barrier plates. The water stop sill and the construction method of the water stop sill have the advantages that through the arrangement and mutual cooperation of the leftbarrier plate, the plurality of middle barrier plates, the right barrier plate, round holes, the support shafts, connecting plates, first threaded holes, fixing screw rods, second threaded holes, clamp connection grooves and clamp connection blocks, the corresponding quantity of the plurality of middle barrier plates can be selected to be combined with the left barrier plate and the right barrierplate according to the length of the water stop sill to be poured; then, the left barrier plate, the plurality of middle barrier plates and the right barrier plate are assembled together through the clamp connection grooves and the clamp connection blocks; then, the left barrier plate, the plurality of middle barrier plates and the right barrier plates can be further fixed through connection by the connecting plates; and the goal of forming a complete formwork is further achieved.

Owner:苏州金世晟建筑装饰工程有限公司

Nozzle for powder spraying device and powder spraying device

PendingCN111495617AEasy to assembleReduce workload and difficultySpray nozzlesLiquid spraying apparatusPhysicsEngineering

The invention provides a nozzle for a powder spraying device and the powder spraying device. The nozzle comprises an outer sleeve, a centering assembly and an inner core, wherein the outer sleeve comprises a first sleeve body and a second sleeve body, the first sleeve body is provided with a first through hole, and the second sleeve body is provided with a second through hole; the centering assembly comprises a positioning cylinder and a positioning core, a channel is formed between the positioning cylinder and the positioning core, the upper end of the positioning cylinder is coaxially connected with the first sleeve body, the lower end of the positioning cylinder is coaxially connected with the second sleeve body, and the channel communicates with the first through hole and the second through hole; and the inner core is arranged in the second through hole, the upper end of the inner core is coaxially connected with the lower end of the positioning core, a cavity communicating with the channel is formed between the inner core and the second sleeve body, and a spraying port is formed between the bottom edge of the second sleeve body and the bottom edge of the inner core. Accordingto the nozzle, by arranging the centering assembly, coaxial assembling of the outer sleeve and the inner core can be achieved, it is guaranteed that the spraying port is a circular ring with a uniformring width, assembling operation is simple, convenient and fast, it is unnecessary to manufacture a tool separately for assembling, and the workload and difficulty of processing and assembling are greatly reduced.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

Steel galvanized group corner combining piece

InactiveCN109629972AEasy and quick assemblyReduce material and labor costsWindow/door framesBuilding materialWelding

The invention relates to the field of building materials, in particular to a steel galvanized group corner combining piece. The steel galvanized group corner combining piece comprises a steel subsidiary frame, an intermediate corner combining section plate is arranged at the corner of the steel subsidiary frame, the two sides of the intermediate corner combining section plate are provided with side edge corner combining section plates respectively, and the side edge corner combining section plates and the intermediate corner combining section plate are fixed through screws. According to the steel galvanized group corner combining piece, the side edge corner combining section plates and the intermediate corner combining section plate cooperate and are fixed through the screws, the steel subsidiary frame is stably fixed, welding is not needed, the structure and performance of sections cannot be damaged, later assembly is simple and quick, and the material and labor cost can be effectively reduced; during construction, wall whitewashing and plastering can be conducted to easily achieve the effect that the exterior is low and the interior is high, the defect that welding is needed whenan existing square pipe replaces the steel subsidiary frame is overcome, and rainwater can also be prevented from penetrating into a room; during installation, gaps between a window and a wall can bemore precise, the function of locating the window can be achieved, and the working efficiency is improved. The problem is solved that since the steel subsidiary frame is made of hot-dip galvanized steel, high-temperature welding is not suitable during later galvanizing processing.

Owner:雷小明 +1

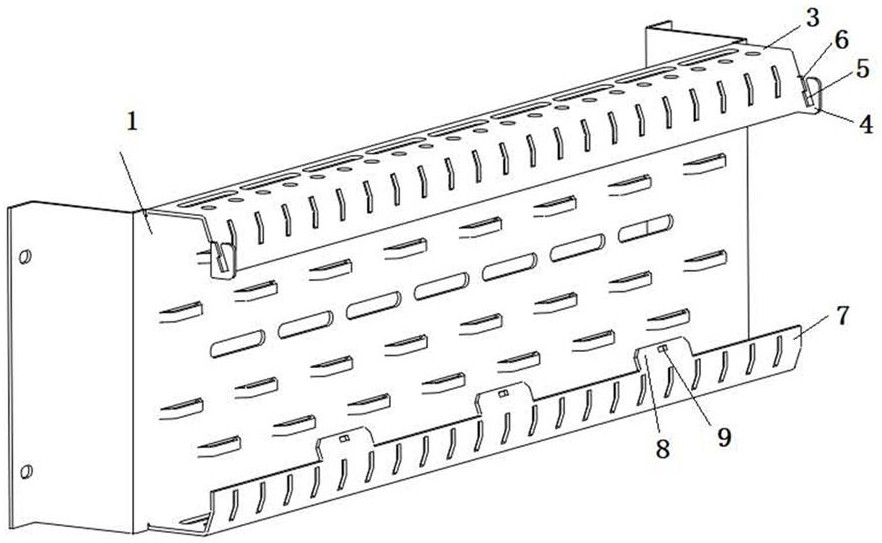

Anti-falling fastener-free cable mounting plate device

PendingCN113285402AReduce labor costsEasy and quick assemblyBus-bar/wiring layoutsCable installation apparatusEngineeringFastener

An anti-falling fastener-free cable mounting plate device belongs to the technical field of industrial cable production and comprises a mounting plate and a cover plate, the top and the bottom of the mounting plate are respectively provided with a mounting plate upper flange and a mounting plate lower flange which extend outwards, the mounting plate upper flange is provided with a hook, the mounting plate lower flange is provided with an insertion plate, the cover plate is provided with a hanging ring matched with the hook, the lower end of the cover plate is provided with an inserting opening matched with the inserting plate, and the mounting plate and the cover plate are buckled and fixed after being connected in an inserting mode through the hanging ring and the hook and connected in an inserting mode through the inserting plate and the inserting opening. The hook and the inclined hook are arranged between the cover plate and the mounting plate, and the angle design is matched, so that the cover plate and the mounting plate can be mounted and dismounted without a fastener, and the purpose of preventing falling is achieved.

Owner:SHENYANG RAILWAY SIGNAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com