Combined hot pan energy-saving device

An energy-saving device and combined technology, applied in the direction of the shell/sleeve of the cooker, can solve the problems of energy consumption, staff discomfort, prolonged cooking time, etc., to achieve simple and fast assembly and disassembly, and shorten the cooking time. Effect of heating time and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] With regard to the inventor's technical means, a preferred embodiment will be described in detail below in conjunction with the drawings, so as to provide an in-depth understanding and recognition of the present invention.

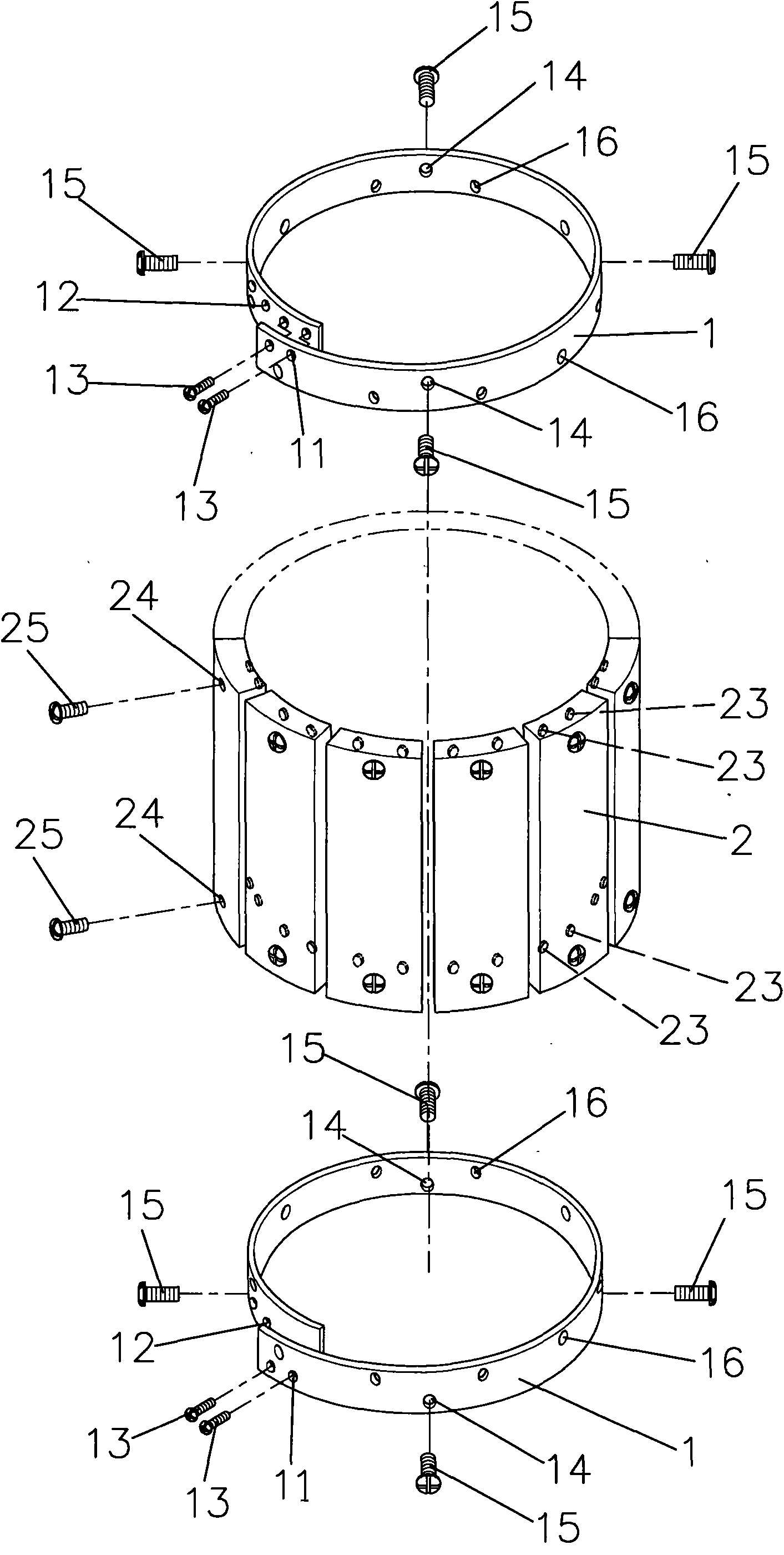

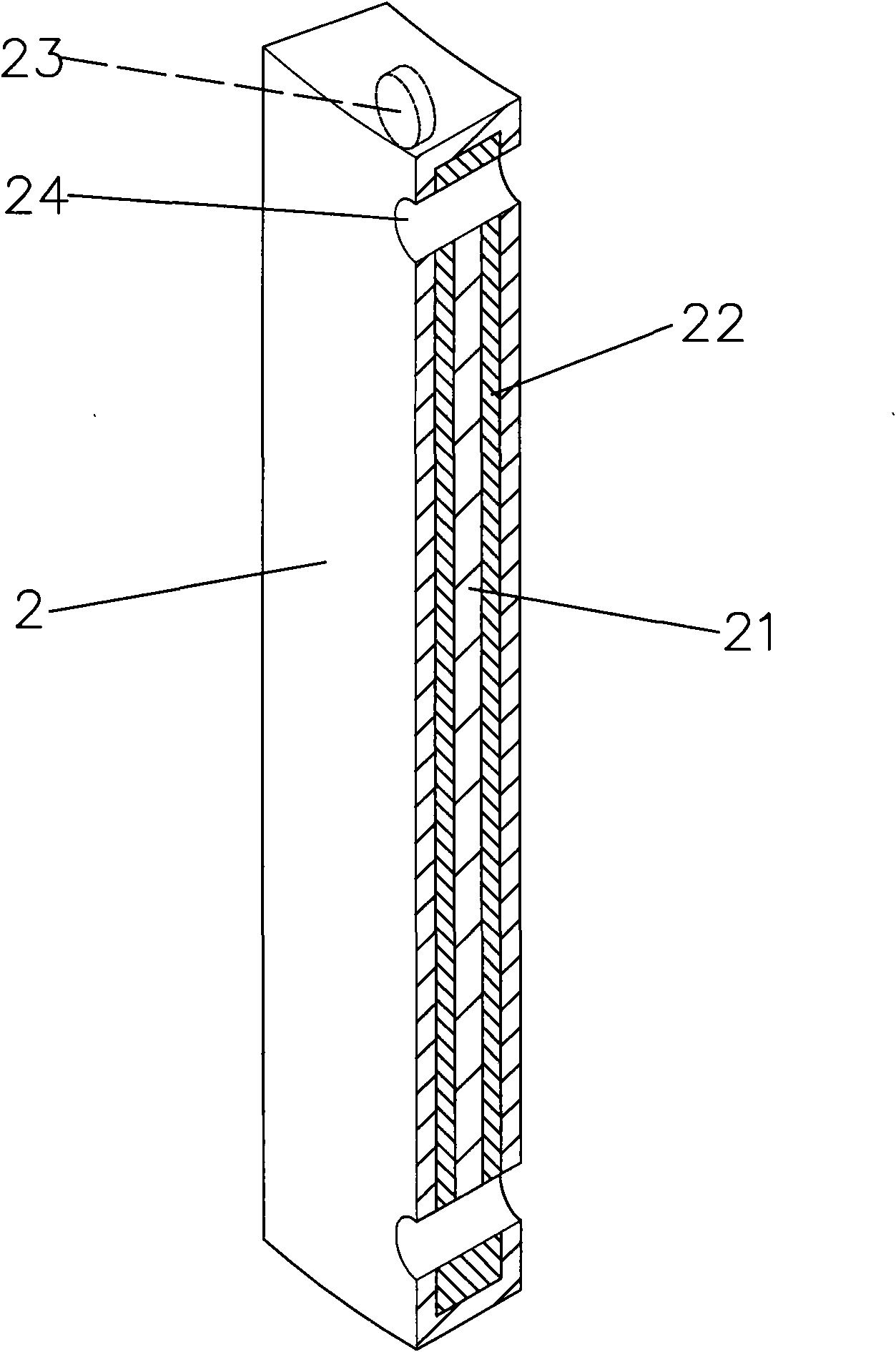

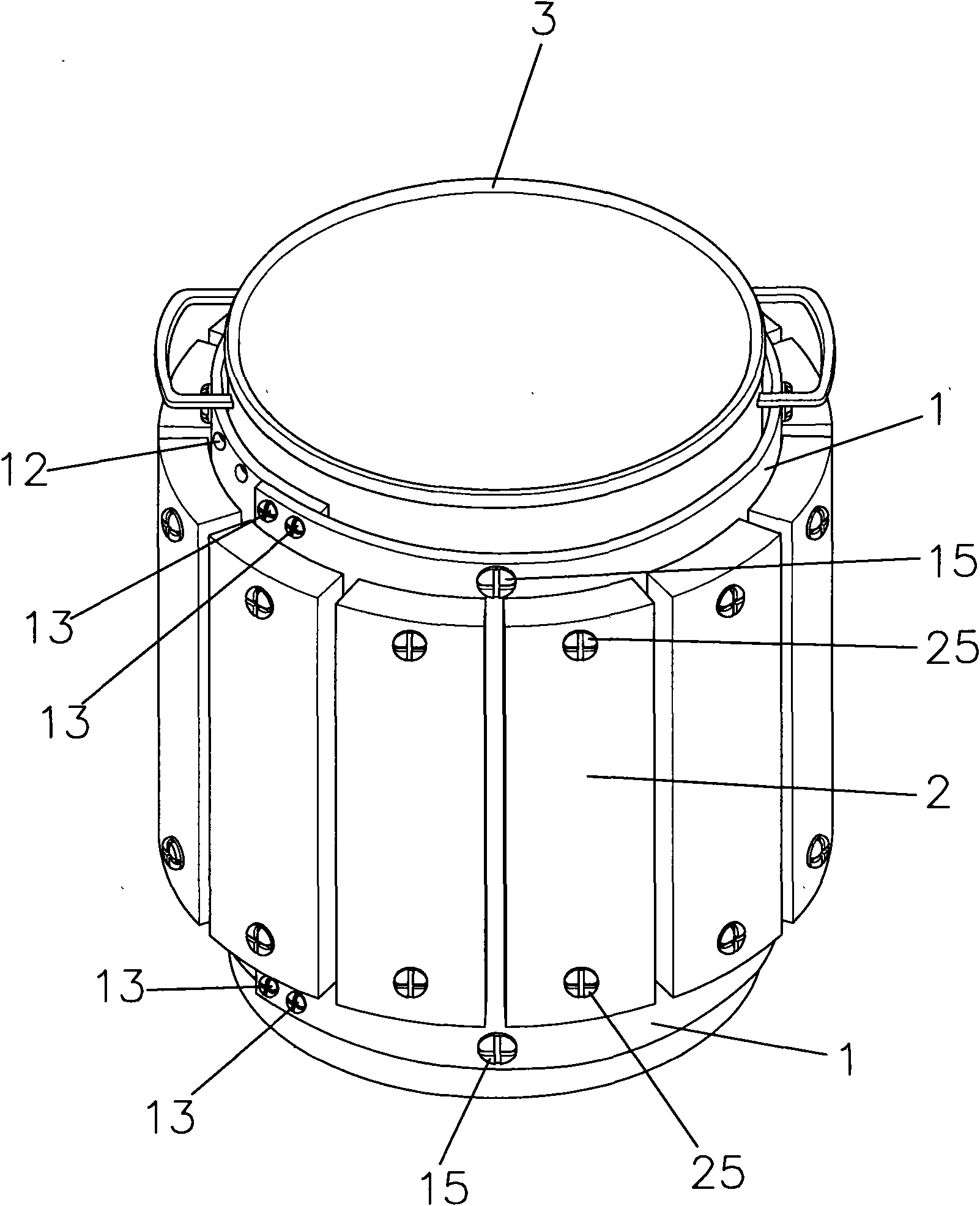

[0027] See first figure 1 , figure 2 As shown, the preferred embodiment of the present invention mainly includes a pair of fixing rings 1 and at least two energy-saving panels 2, wherein:

[0028] The pair of fixed rings 1 is a strip made of metal material (preferably magnetic stainless steel), such as figure 1 As shown, one end of the belt-shaped body is provided with a locking hole 11, and the other end is provided with a plurality of adjustment holes 12. The locking holes 11 can correspond to the adjustment holes 12 and are pierced by locking elements 13. Locking to form a fixed ring 1, the fixed ring 1 is provided with a plurality of through holes 14, the through holes 14 can be used for the locking element 15 to pass through, and the fixed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com