Ceramic resistor type spark plug cap of motorcycle

A technology of spark plug caps and ceramic resistors, which is applied in the direction of spark plugs, circuits, electrical components, etc., can solve the problems of poor contact between the end face of the resistor and the screw, the residue is not easy to clean, and the poor conductivity between the spring and the resistor. Non-conduction phenomenon, simple structure, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

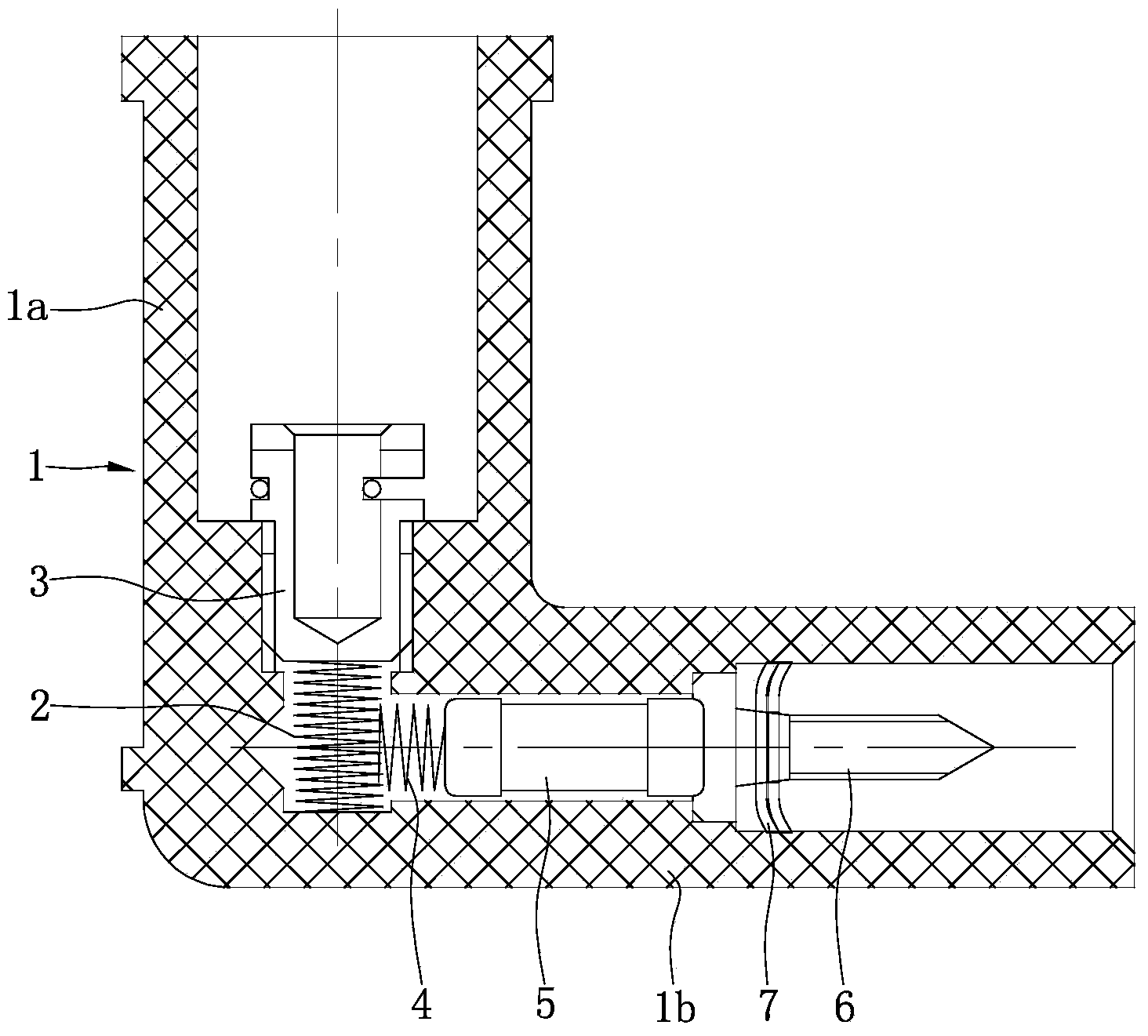

[0022] Such as figure 1 As shown, the body 1 of the ceramic resistance motorcycle spark plug cap is formed by injection molding and is composed of a first straight pipe 1a and a second straight pipe 1b perpendicular to each other. The outline of the body 1 is "L". The inner hole of the first straight pipe 1a communicates with the inner hole of the second straight pipe 1b to form an "L"-shaped accommodation space. The first spring 2 and the conductive cap 3 are installed in the first straight pipe 1a. One end of the first spring 2 is in contact with the bottom of the inner hole of the first straight pipe 1a, and the other end is in contact with the conductive cap 3. The conductive cap 3 is in contact with the bottom of the first straight pipe 1a. The first straight pipe 1a is threaded.

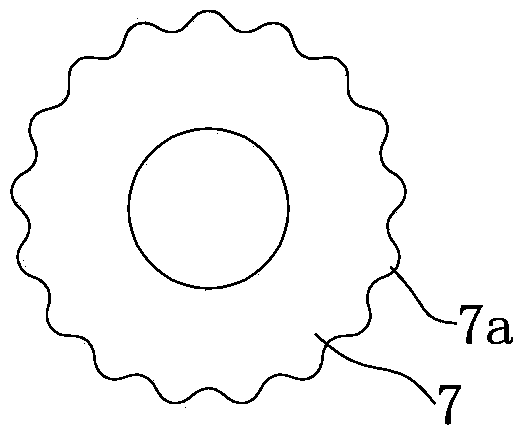

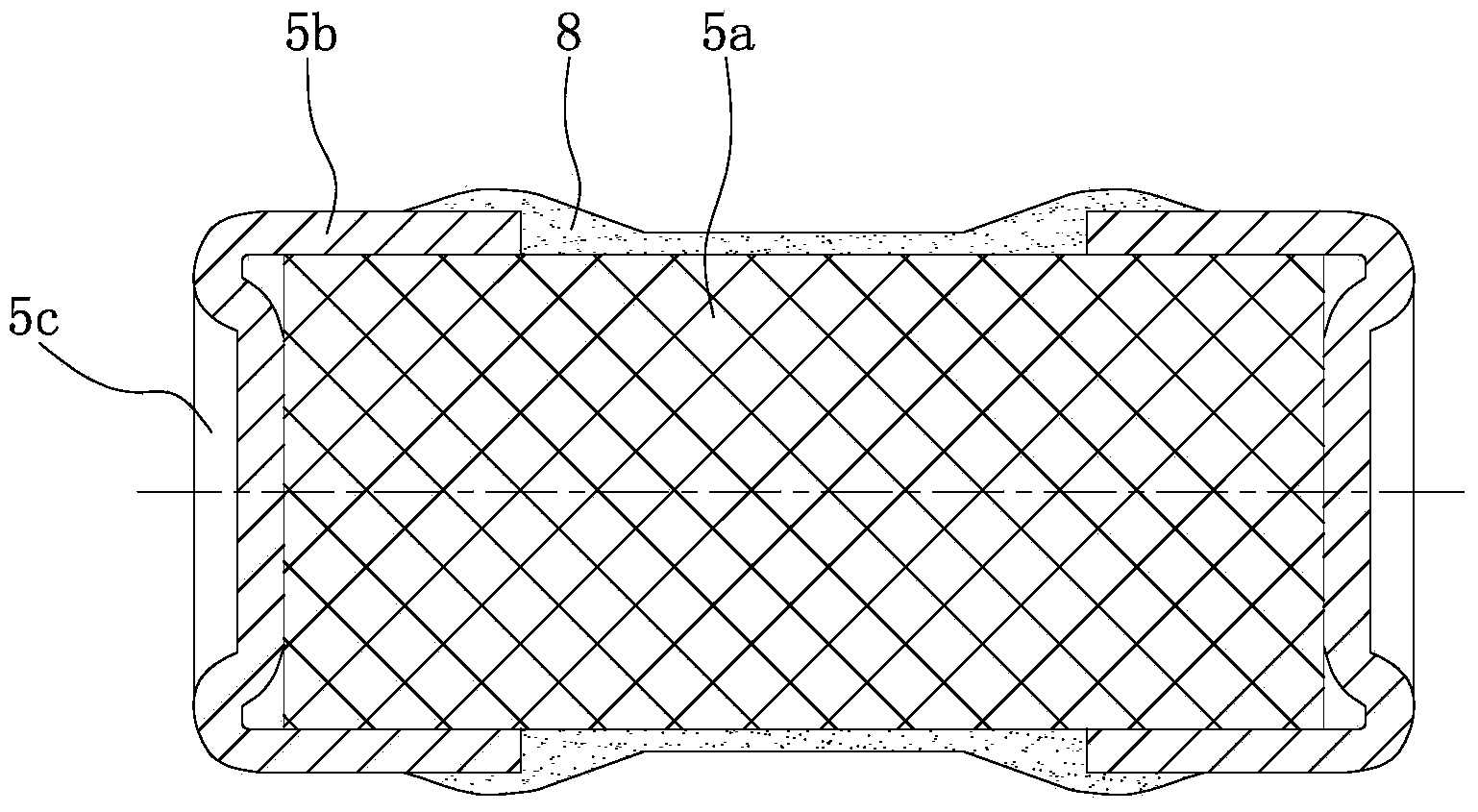

[0023] Such as figure 1 , image 3 As shown, the inner hole of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com