Spark plug cap production technology

A production process and spark plug cap technology, which is applied in the field of spark plug cap production technology, can solve the problems of difficult cleaning of residues, poor continuity between springs and resistors, and poor spring positioning reliability, so as to prevent poor product conduction and avoid The effect of scalding and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

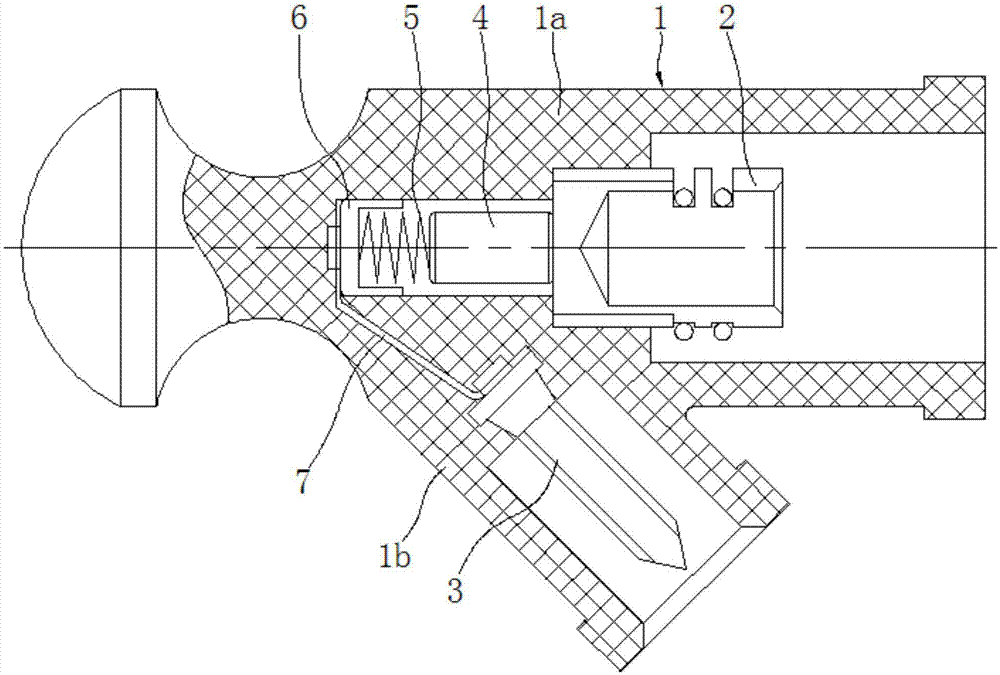

[0017] Such as figure 1 Shown, the production steps of the present invention are as follows:

[0018] 1) Set one end of the connecting piece 7 on the first boss integrally formed on the head of the resistance cap 6 at room temperature, and fix it by riveting; the other end of the connecting piece 7 is set on the first boss integrally formed on the head of the self-tapping screw 3 . The two bosses are also fixed by riveting; the resistance cap 6, the connecting piece 7 and the self-tapping screw 3 form a screw assembly.

[0019] 2) Install the screw assembly on the mold core, put the mold core into the mold, and produce the body 1 through the injection molding process, so that the screw assembly is located in the body 1, the head of the resistance cap 6 and the head of the self-tapping screw 3 And the connecting piece 7 is covered by the rubber of the main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com